Drying and incineration system

A drying and incinerator technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of uneven incineration, insufficient thermal efficiency, low production efficiency, etc. of incinerators, and achieve improved mechanical stirring effect and thermal efficiency and production efficiency, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

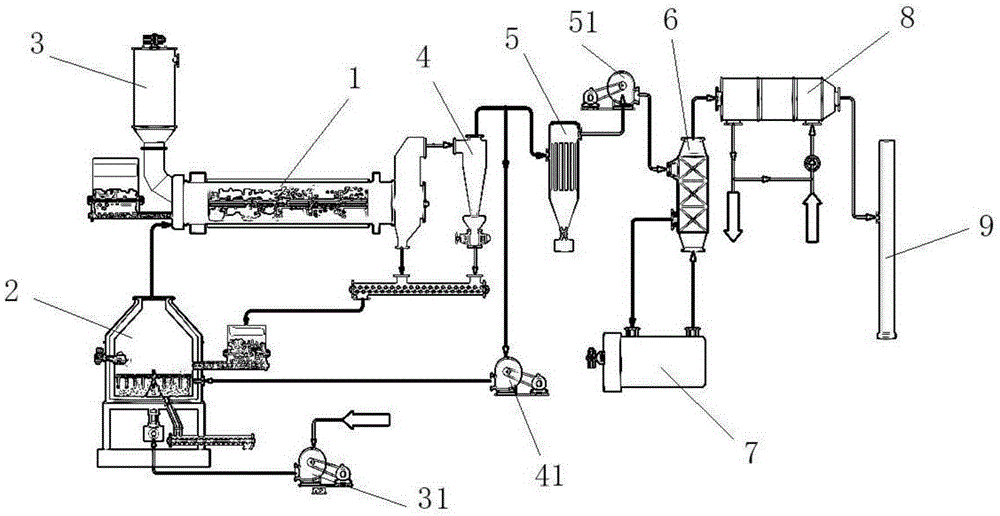

[0054] This embodiment provides a dry incineration system, such as figure 1 mentioned, including

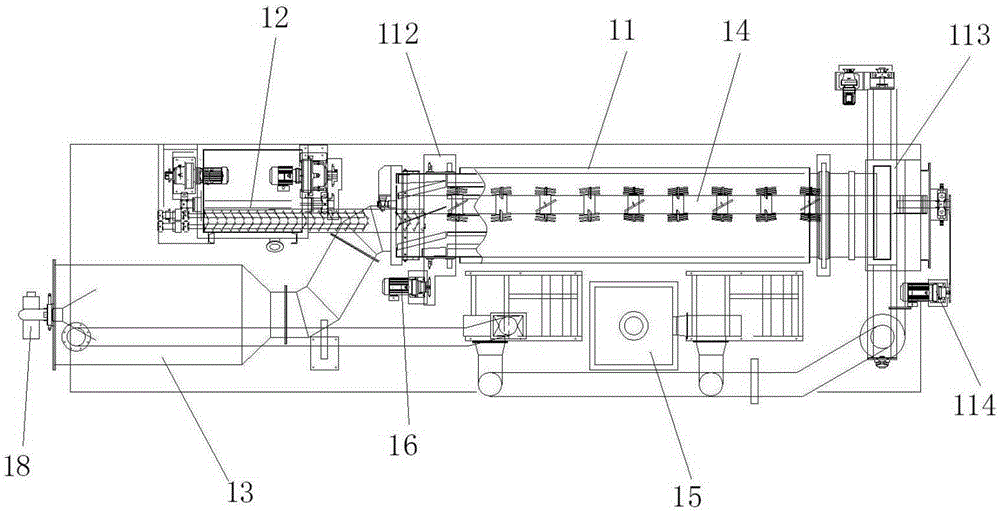

[0055] Drying equipment 1, used for drying materials, has a gas inlet and a gas outlet;

[0056] A hot blast generator 3 communicates with the gas inlet for feeding hot blast into the drying equipment 1;

[0057] The incineration equipment 2 is used to receive the materials dried by the drying equipment 1;

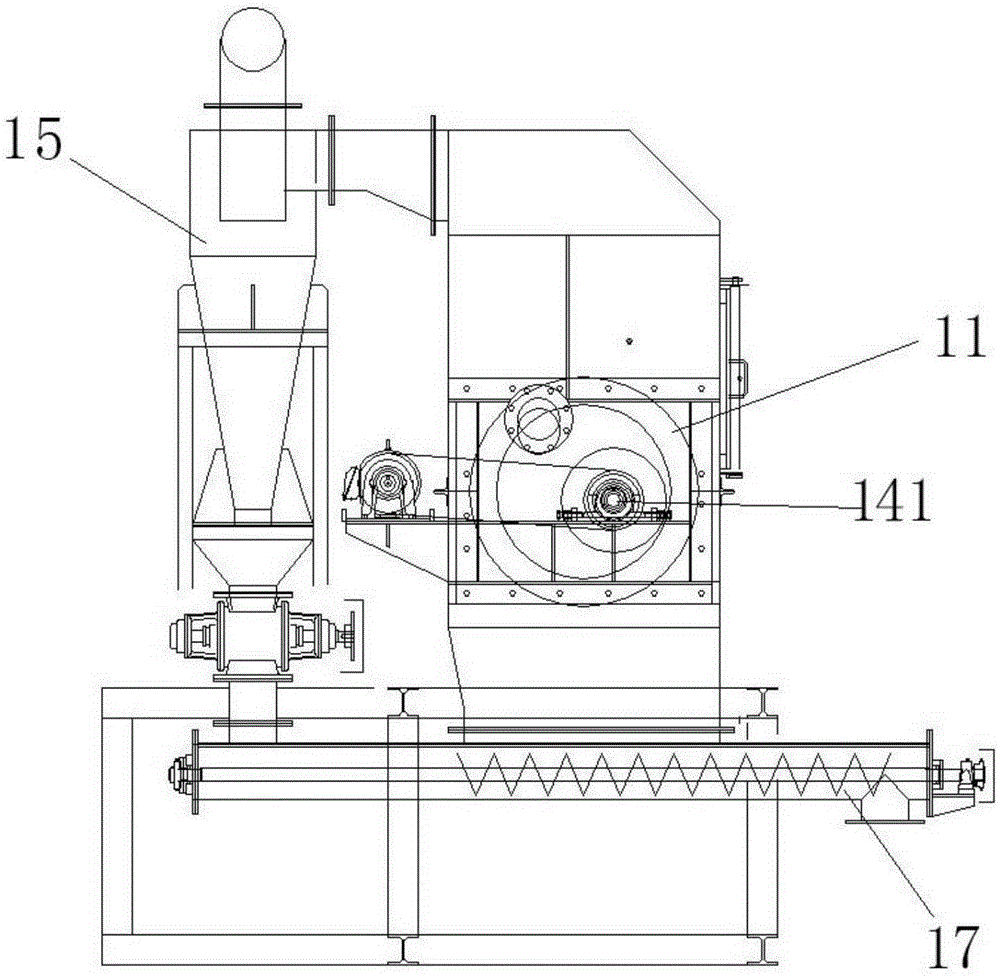

[0058] The incineration equipment 2, such as Figure 5 or 6, including

[0059] The incinerator 22 has a feed inlet 221 and a high-temperature gas tuyere 225 on the side wall, an air outlet 223 on the top, and a discharge outlet 222 on the bottom;

[0060] The burner 25 communicates with the high-temperature gas tuyere 225 and is used for blowing high-temperature gas into the interior of the incinerator 22;

[0061] stirring device, such as Figure 7 or 8, for stirring the materials in the incinerator 22;

[0062] The stirring device includes a rotating shaft 211, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com