Position sensing device and method using self-capacitance

A technology for sensing equipment and sensing methods, applied in the direction of transmitting sensing components, electronic switches, and measuring devices using electric/magnetic devices, which can solve the problems of unreliable sensors, late warnings, and difficulty in monitoring pollution with capacitive position sensors. problem, achieving a simple and economical absolute measurement system with low additional costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

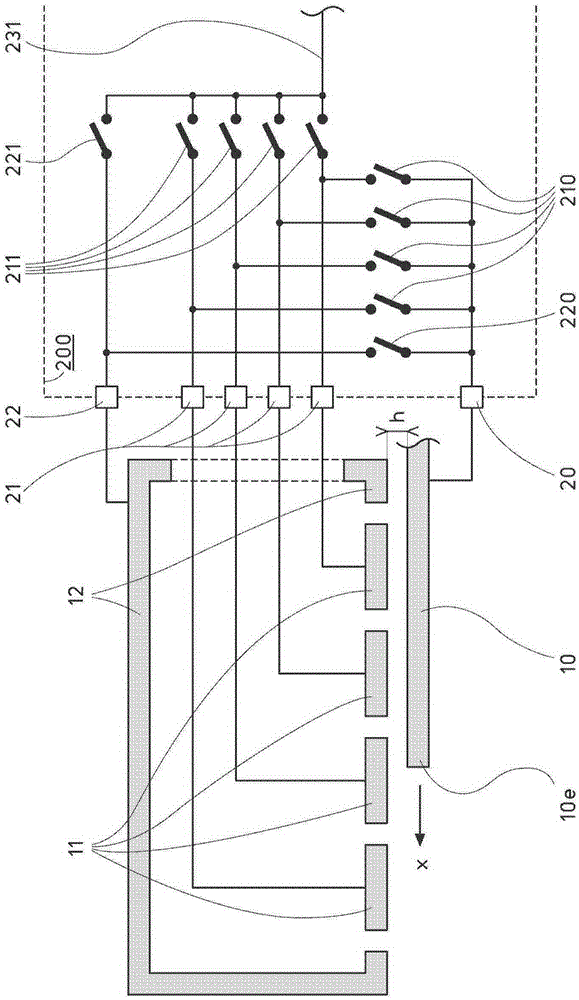

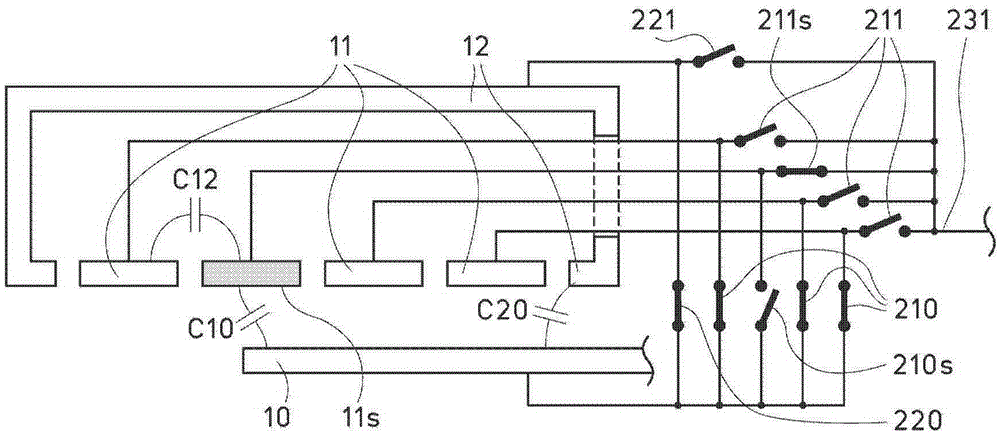

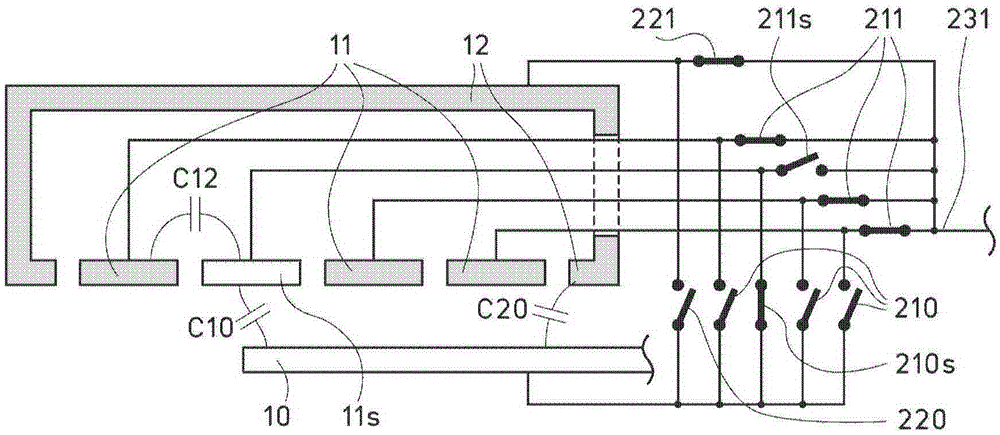

[0031] The position sensor described here is based on the measurement of the self-capacitance of the electrodes to use a microcontroller with integrated touch sensing electronics, of course any suitable circuit can be used to measure the self-capacitance instead. The circuit must be capable of measuring self-capacitance on one or more sense pads or sense pins by switching the one or more sense pads or pins to a capacitance that is linear enough for the required accuracy- digitizer while simultaneously switching it and the sense pad to ground to achieve the measurement.

[0032] An example of a capacitive sensing microcontroller that meets these requirements is the Silicon Labs (Silicon Labs) C8051F99x, which operates by connecting the sense pads, or any group of up to 14 sense pads, to a continuous approximation of capacitance - Digitizers (of the type disclosed in US Patent 8'193'822 to Welland) to measure their self-capacitance. The converter's most sensitive range is about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com