In-situ detection method of polarization aberration of projection objective lens of lithography machine

A technology of projection objective lens and lithography machine, which is applied in the field of lithography machine, and can solve the problems of small number of aberrations, low measurement accuracy of polarization attenuation and polarization delay components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the examples and drawings, but the examples should not limit the protection scope of the present invention.

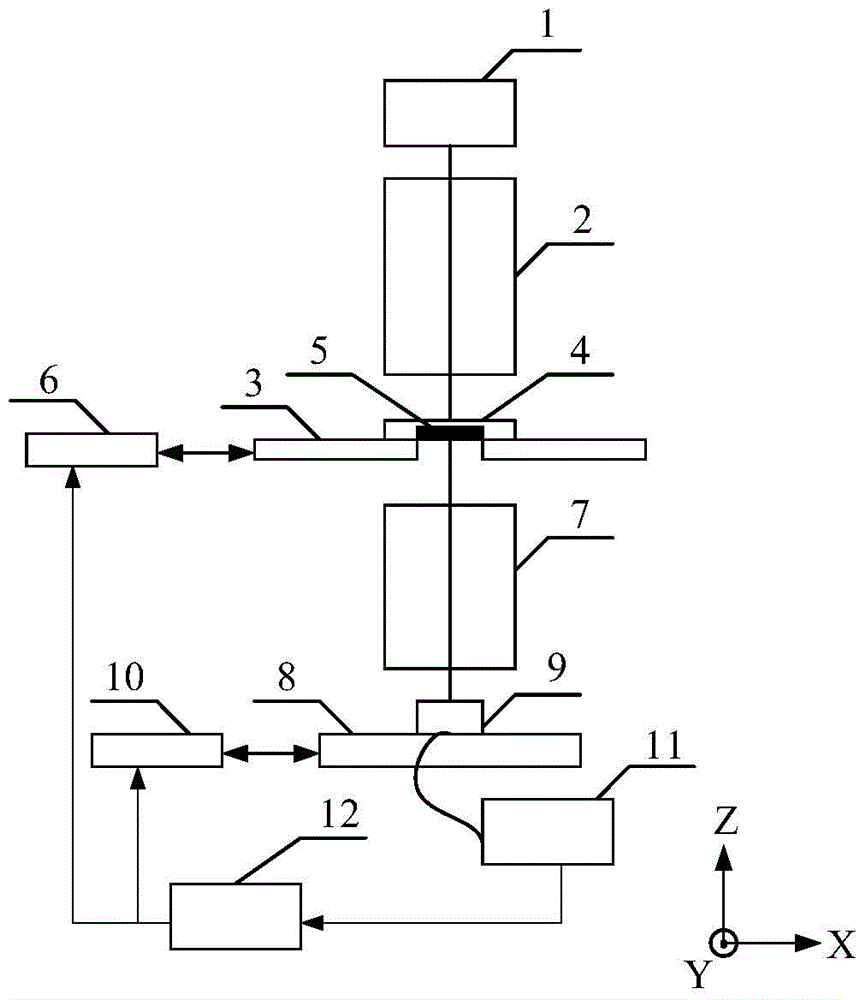

[0078] figure 1 Schematic diagram of the structure of the projection objective polarization aberration detection system used in the present invention, including a light source 1 that generates an illumination beam, an illumination system that adjusts the illumination mode (including polarization illumination mode) and partial coherence factor of the beam emitted by the light source 1 and makes the beam uniformly illuminated 2. A mask table equipped with a mask and using a positioning system 6 to achieve precise positioning 3. A mask 4 including a polarization aberration detection mark 5. A projection objective lens with large numerical aperture capable of imaging the mask pattern and having an adjustable numerical aperture 7. A workpiece table 8 capable of carrying silicon wafers and using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com