Air filtration material and manufacturing method thereof

A technology of air filter material and filter screen, which is applied in the field of composite air filter material and its manufacturing, can solve the problems of weakened filtering capacity of tiny dust particles, loss of electrostatic adsorption capacity of filter material, and negative effects, etc., so as to achieve easy control of production costs, The effect of easy weaving and brushing process and sewing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

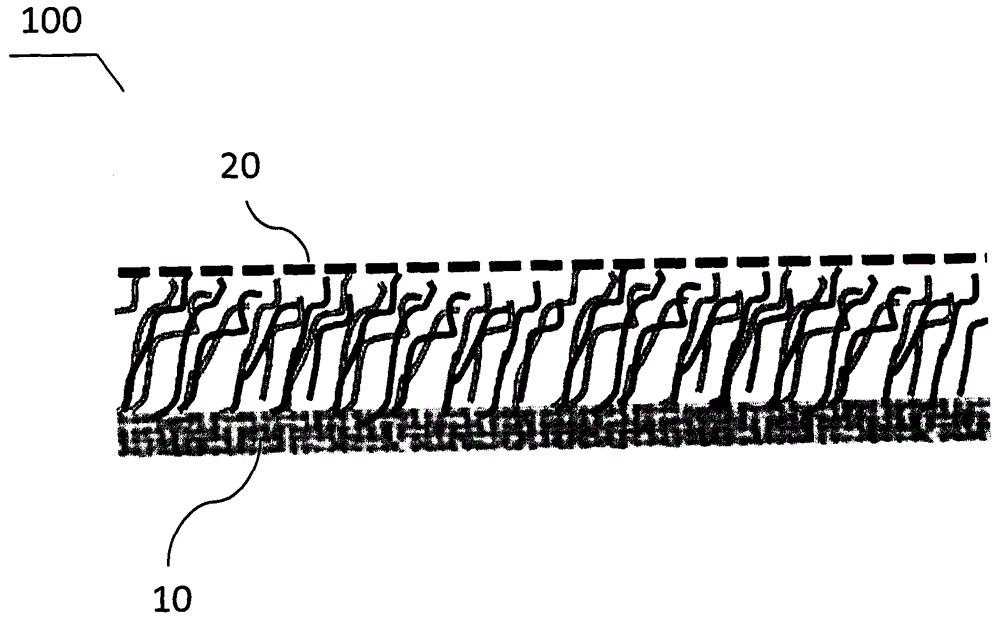

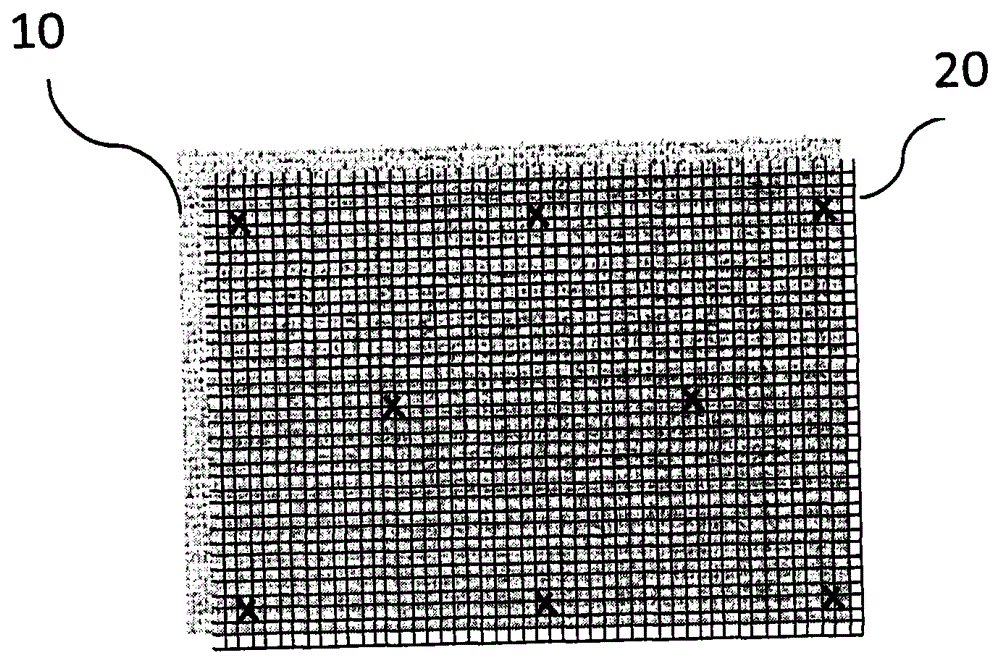

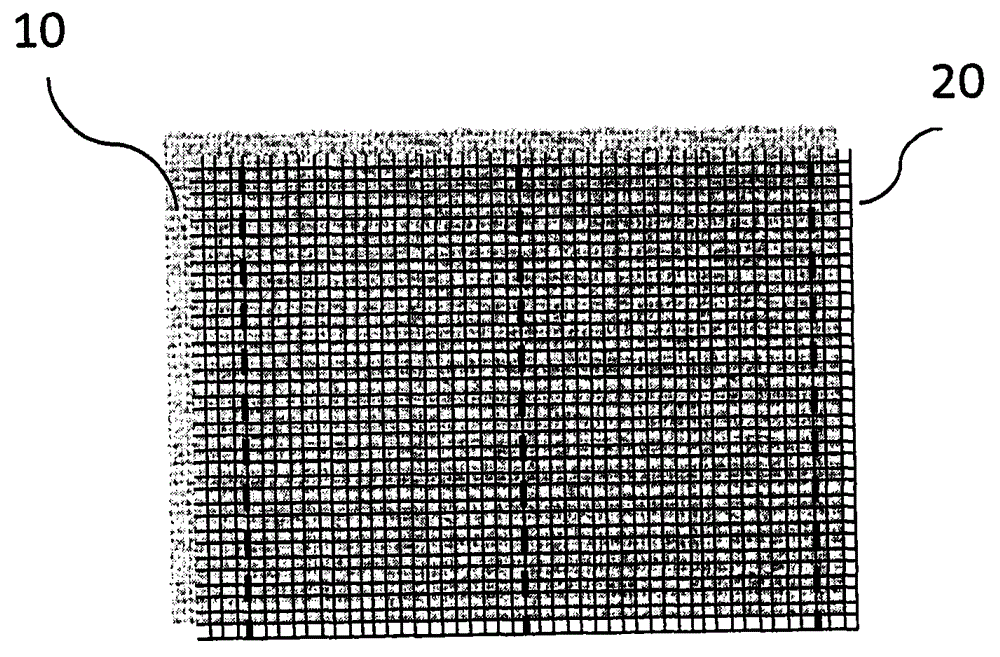

[0025] According to one embodiment of the present invention, figure 1 A schematic cross-sectional view of an air filter material 100 is shown. As shown in the figure, the air filter material 100 may include a blended brushed filter cloth made by blending a first polymer fiber and a second polymer fiber in a ratio of 1:1 10. The brushed surface of the blended brushed filter cloth 10 is sewn with nylon mesh 20 . According to another embodiment of the present invention, the nylon mesh 20 may also be a polytetrafluoroethylene filter mesh.

[0026] In order to achieve a better filtering effect, the aperture of the nylon mesh 20 (or polytetrafluoroethylene filter mesh) can be selected as 180-300 mesh.

[0027] According to an embodiment of the present invention, the first polymer fiber may be a single polyester fiber or a single acrylic fiber, or a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com