Combined layered dredging multifunctional raw material warehouse

A multi-functional, raw material warehouse technology, applied in the field of biomass bulk raw material storage, can solve problems such as unreasonable design, easy blockage, no dredging means, etc., to eliminate the "dead angle" of dredging, avoid bridging, and prevent material blockage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

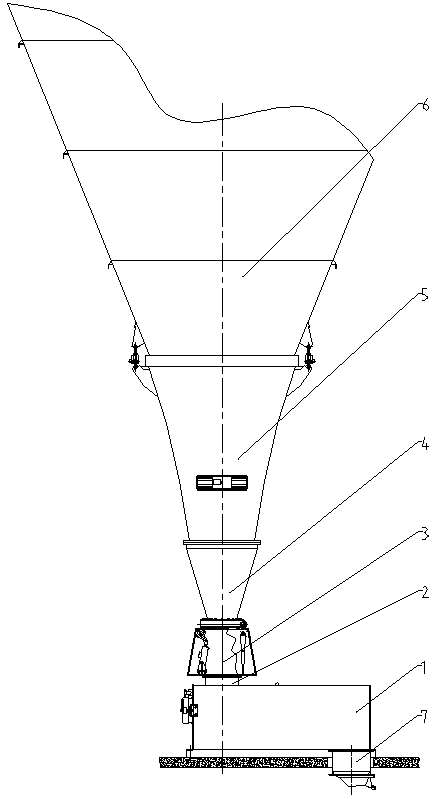

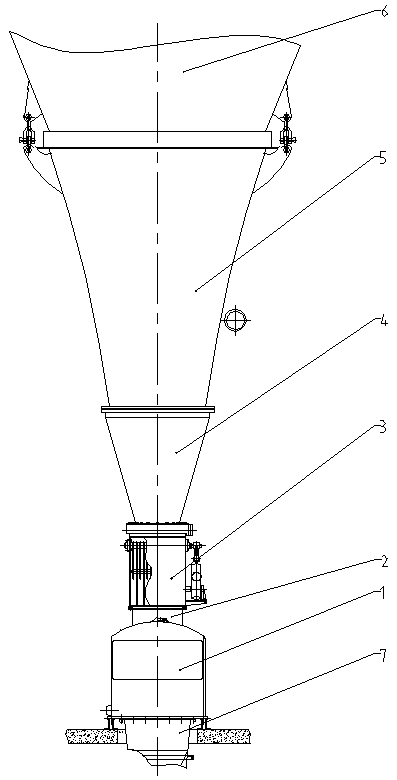

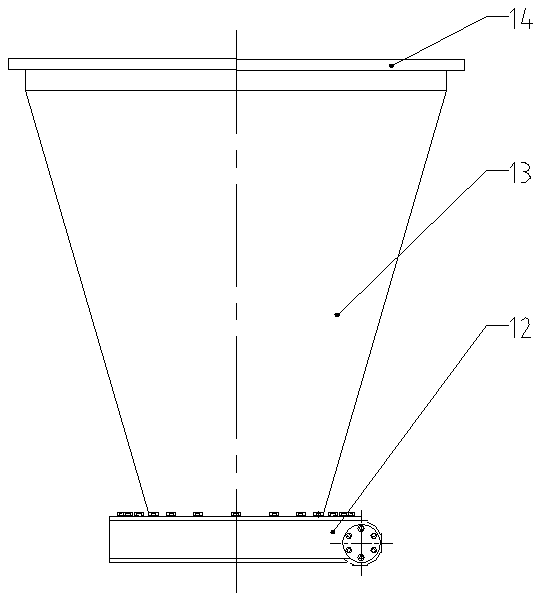

[0026] Firstly, the embodiment of the present invention is generally described in conjunction with the accompanying drawings: Figure 6 As shown, when the biomass raw material is stored in the raw material bin 6 and flows by its own weight from top to bottom, since the upper mouth of the raw material bin 6 is large and the lower mouth is small, and the outlet of the raw material bin 2 is provided with a riser from bottom to top. Section 19 and panel door (bar) 20 (and itself does not have dredging means again). Such design and setting can easily cause the raw material to stick to the wall, arch or block here.

[0027] Such as figure 1 , figure 2 As shown, when the raw material is blocked in the raw material bin 6, it will cause the raw material bin outlet 2, feeder 1, feeder outlet 7 and downstream equipment to be cut off. At this time, the present invention can receive the material breaking signal and start working sequentially from the multifunctional palate dredging dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com