A treatment process for reuse of reclaimed water

A treatment process and reclaimed water technology, which is applied in the field of water treatment, can solve the problems of security filter fouling, reverse osmosis membrane fouling, reverse osmosis device inlet water not up to standard, etc., to achieve the effect of preventing blockage and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

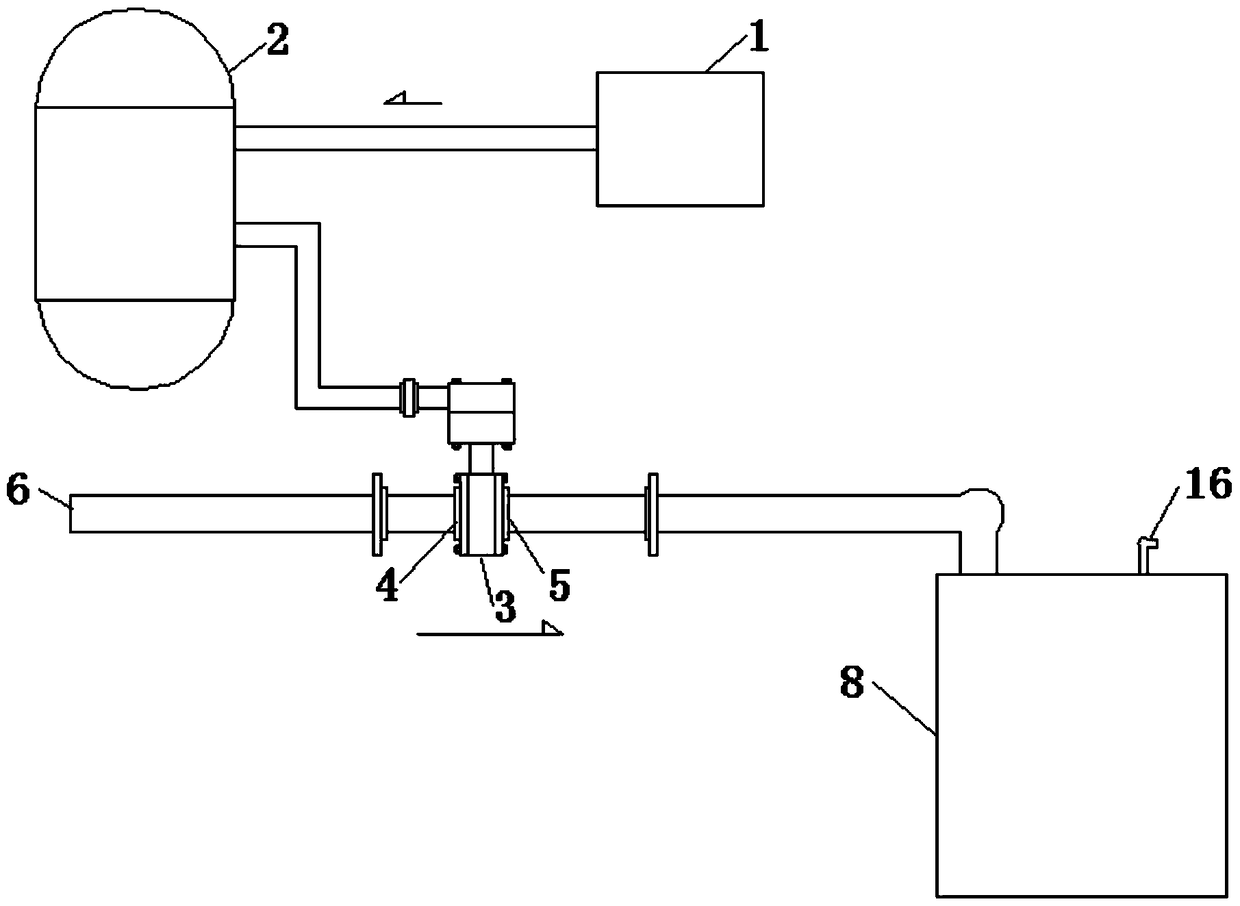

[0028] This embodiment provides a treatment process for reuse of reclaimed water. The process uses circulating water and sewage as raw water, and performs ozone aeration treatment before the raw water enters the reuse water tank, oxidizes and sterilizes, and oxidizes ferrous ions in the water body. into ferric ions to remove dissolved carbon dioxide in water.

[0029] The treatment process of reclaimed water reuse in this embodiment avoids adjusting the water body to alkaline conditions in the subsequent treatment process of reclaimed water reuse to remove dissolved carbon dioxide in the water body, thereby avoiding or reducing the generation of silica colloids or gels, Thus, the condition of acidic water inflow to the reverse osmosis membrane of the reverse osmosis device used in the follow-up treatment process of reclaimed water is satisfied, the clogging of the reverse osmosis membrane is prevented, and the service life of the reverse osmosis membrane is prolonged. Replenis...

Embodiment 2

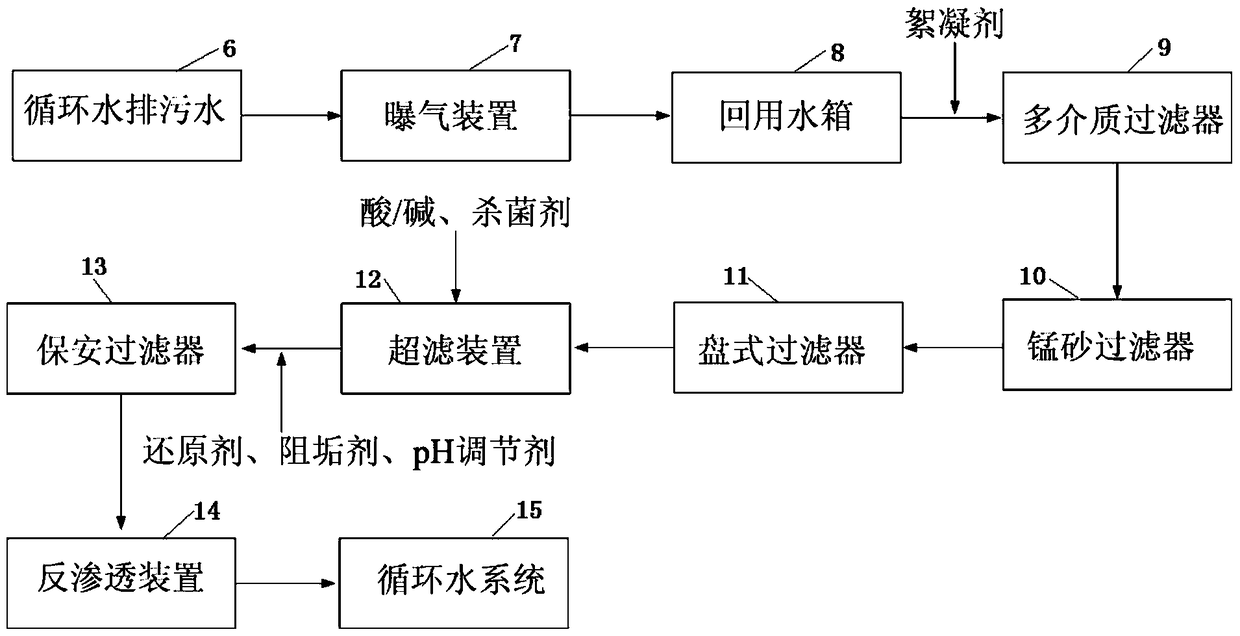

[0031] Such as figure 1 As shown, the present embodiment provides a treatment process for reclaimed water, comprising the following steps:

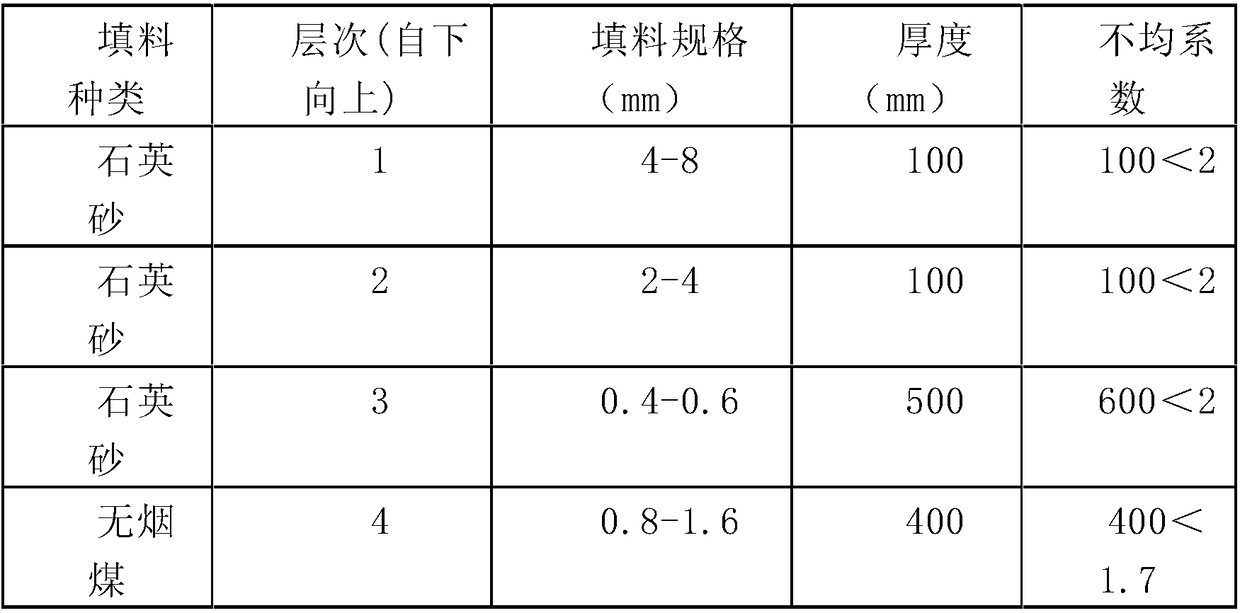

[0032] The circulating water sewage 6 is used as raw water, and before the raw water enters the reuse water tank 8, ozone aeration treatment is performed to oxidize and sterilize, and ferrous ions in the water body are oxidized to ferric ions. Preferably, the concentration of iron ions in the circulating water sewage 6 is 0.3-1.0 mg / L. Add ozone aeration treatment before entering the reuse water tank 8, utilize the oxidation and sterilization properties of ozone, pass ozone into the raw water for sterilization, and remove dissolved carbon dioxide in the water body. The silicon dioxide in the circulating water sewage 6 in this embodiment exceeds the standard.

[0033] The treatment process of reclaimed water reuse in this embodiment avoids adjusting the water body to alkaline conditions in the subsequent treatment process of reclaimed wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com