Rose sparking wine and production method thereof

A production method, rose technology, applied in the production field of rose sparkling wine and rose sparkling wine, can solve problems such as high alcohol content, lower nutritional value of roses, and restriction of consumer groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

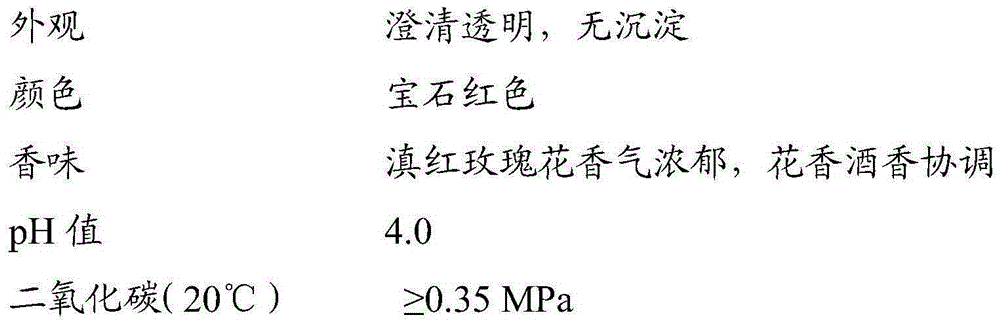

[0090] Embodiment 1: the production of rose sparkling wine

[0091] The implementation steps of this embodiment are as follows:

[0092] A. Rose screening

[0093] The pollen sac and calyx of the mature Dianhong rose are removed, and the red rose petals with good quality and color are selected; the water content of the fresh rose is determined to be 80% by weight by drying and weight loss method.

[0094] B. Leaching

[0095] Rose petals in kilograms: sterile water in kilograms: food-grade citric acid in grams: potassium metabisulfite in milligrams The mass ratio is 1:1.0:38:55, the rose petals, sterile Water, food-grade citric acid and potassium metabisulfite were mixed evenly, and then placed in a light-proof airtight container sold by Langfang Aosen Steel Aluminum Container Co., Ltd. under the trade name of stainless steel extraction tank, and extracted at a temperature of 30 ° C for 8.5 hours; Then, according to the 35 mg pectinase per liter of the extraction mixture, t...

Embodiment 2

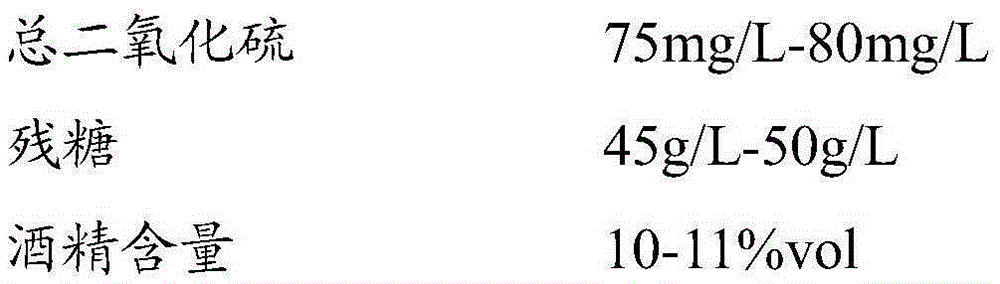

[0104] Embodiment 2: the production of rose sparkling wine

[0105] The implementation steps of this embodiment are as follows:

[0106] A. Rose screening

[0107] The pollen sacs and calyxes of mature Dianhong roses are removed, and red rose petals with good quality and color are selected; the water content of the fresh roses is determined to be 82% by weight by drying and weight loss method.

[0108] B. Leaching

[0109] Rose petals in kilograms: sterile water in kilograms: food-grade citric acid in grams: potassium metabisulfite in milligrams The mass ratio is 1:1.0:38:55, the rose petals, sterile Water, food-grade citric acid and potassium metabisulfite were mixed evenly, and then placed in a light-proof airtight container sold by Langfang Aosen Steel Aluminum Container Co., Ltd. under the trade name of stainless steel extraction tank, and extracted at a temperature of 35 ° C for 8.0 hours; Next, according to 20 mg of pectinase per liter of the extraction mixture, the p...

Embodiment 3

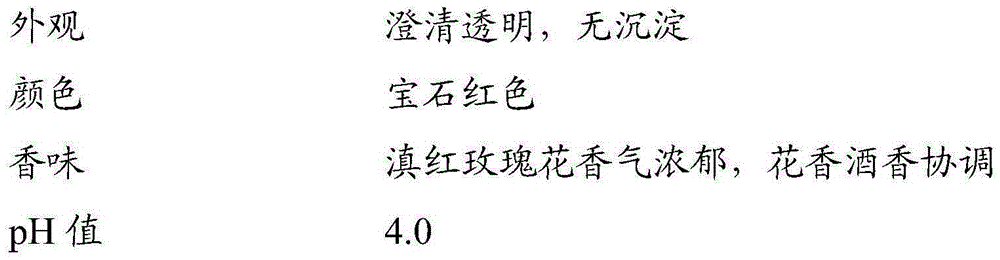

[0118] Embodiment 3: the production of rose sparkling wine

[0119] The implementation steps of this embodiment are as follows:

[0120] A. Rose screening

[0121] The pollen sac and calyx of the mature Dianhong rose are removed, and the red rose petals with good quality and color are selected; the water content of the fresh rose is determined to be 85% by weight by drying and weight loss method.

[0122] B. Leaching

[0123] Rose petals in kilograms: sterile water in kilograms: food-grade citric acid in grams: potassium metabisulfite in milligrams The mass ratio is 1:1.0:38:55, the rose petals, sterile Water, food-grade citric acid and potassium metabisulfite are mixed evenly, and then placed in a light-proof airtight container sold by Langfang Aosen Steel Aluminum Container Co., Ltd. under the trade name of stainless steel extraction tank, and extracted at a temperature of 40 ° C for 7.5 hours; Next, according to 50 mg of pectinase per liter of the extraction mixture, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com