A kind of production method of apple cicadae health wine

A production method and technology for health-care wine, which are applied in the production field of apple cicada flower health-care wine, can solve the problems of high alcohol content, long cultivation period, light wine fragrance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

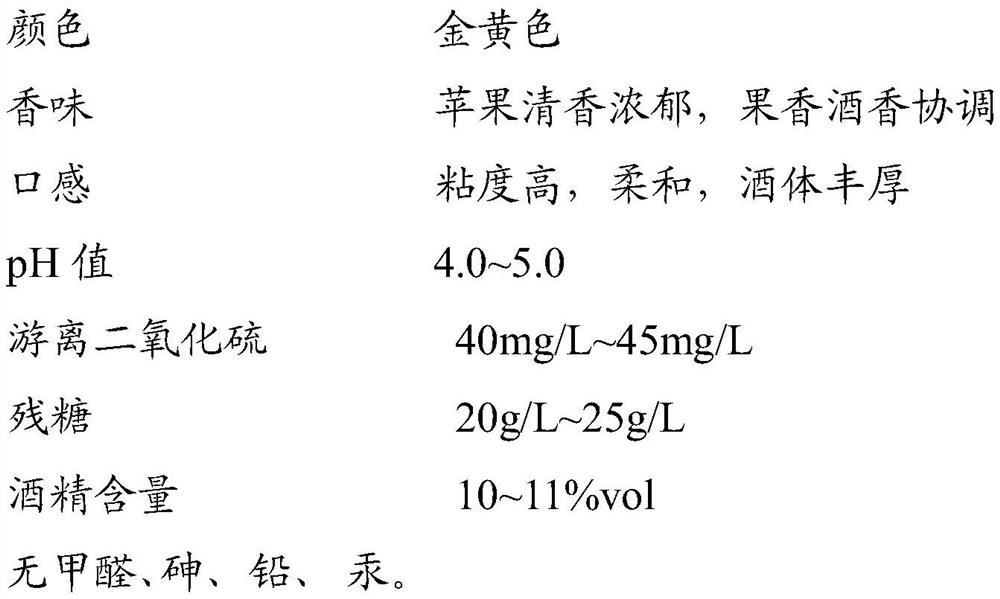

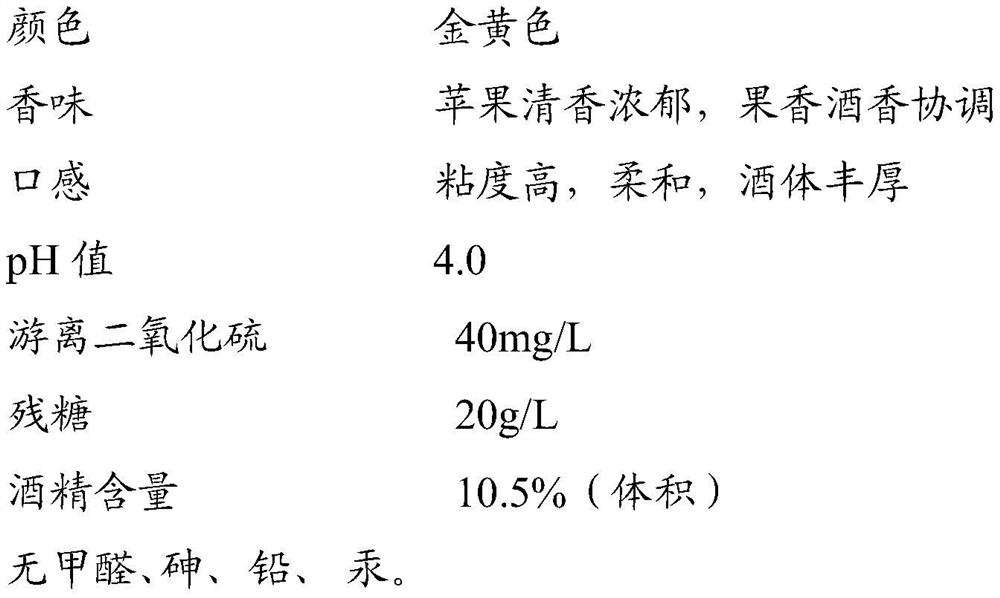

Embodiment 1

[0111] Embodiment 1: production of apple cicadae health wine of the present invention

[0112] The implementation steps of this embodiment are as follows:

[0113] A. Raw material pretreatment

[0114] Ripe high-quality red Fuji apples with a sugar content of 17.2% by mass are selected, peeled, cored, and cut into 0.8cm in size 3 apple chunks, set aside;

[0115] B. Preparation of Cicada apple culture medium

[0116] According to the ratio of sterile water in kilograms, sucrose in grams, food-grade citric acid in grams to ascorbic acid in grams is 1.1:22:3.2:0.1, mix sterile water, sucrose, food-grade citric acid and ascorbic acid Evenly, boil, then add the apple pieces obtained in step A with the same quality as sterile water, continue to boil for 20min, then cool to room temperature, filter, and adjust the pH value of the filtrate to 6.5 with food-grade sodium citrate, and then heat it at a temperature of 115 Sterilize at ℃ for 20 minutes, and cool to obtain the cicadae ...

Embodiment 2

[0134] Embodiment 2: production of apple cicadae health wine of the present invention

[0135] The implementation steps of this embodiment are as follows:

[0136] A. Raw material pretreatment

[0137] Ripe high-quality Red Star apples with a sugar content of 16.0% by mass are selected, peeled, cored, and cut into a size of 1.0cm 3 apple chunks, set aside;

[0138] B. Preparation of Cicada apple culture medium

[0139] According to the ratio of sterile water in kilograms, sucrose in grams, food-grade citric acid in grams to ascorbic acid in grams is 1.2:20:2.5:0.12, mix sterile water, sucrose, food-grade citric acid and ascorbic acid Mix well, boil, then add the apple pieces obtained in step A with the same quality of sterile water, continue to boil for 25min, then cool to room temperature, filter, and adjust the pH value of the filtrate to 6.2 with food-grade sodium citrate, and then add it at a temperature of 115 Sterilize at ℃ for 20 minutes, and cool to obtain the cica...

Embodiment 3

[0158] Embodiment 3: production of apple cicadae health wine of the present invention

[0159] The implementation steps of this embodiment are as follows:

[0160] A. Raw material pretreatment

[0161] Choose ripe high-quality Marshal Huang apples with a sugar content of 16.6% by mass, peel and remove the core, and then cut into a size of 1.2cm 3 apple chunks, set aside;

[0162] B. Preparation of Cicada apple culture medium

[0163] According to the ratio of sterile water in kilograms, sucrose in grams, food-grade citric acid in grams to ascorbic acid in grams is 1.1:25:2.9:0.14, mix sterile water, sucrose, food-grade citric acid and ascorbic acid Evenly, boil, then add the apple pieces obtained in step A with the same quality as sterile water, continue to boil for 22min, then cool to room temperature, filter, and adjust the pH value of the filtrate to 6.0 with food-grade sodium citrate, and then heat it at a temperature of 115 Sterilize at ℃ for 20 minutes, and cool to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com