Foam glass heat-insulation layer construction method

A foam glass and construction method technology, applied in thermal insulation, building components and other directions, can solve the problems of inconvenient construction method of foam glass thermal insulation layer, poor laying effect of foam glass thermal insulation layer, complicated production process, etc. The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

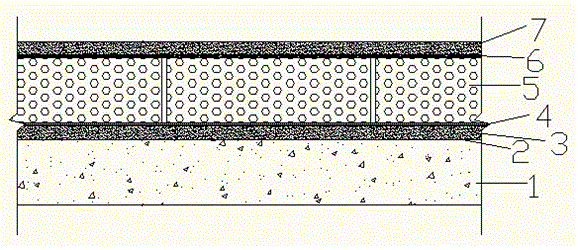

[0038] see now figure 1 , figure 1 It is a structural schematic diagram of the foam glass insulation layer of the embodiment of the present invention. As shown in the figure, the

[0039] The construction method of the foam glass insulation layer of the present invention, its operating conditions: the roof base should be leveled, its slope, separation joints, etc. The on-site representatives of the unit, the general contractor, the supervisory unit, and our company have passed the inspection and acceptance, and the ventilation pipes, flues, and embedded parts that go out of the roof should be installed in advance.

[0040] The foam glass insulation layer construction method of the present invention is characterized in that comprising the following steps:

[0041] a. Material preparation, transportation and storage of foam glass plates

[0042] b. Lay foam glass insulation layer on the roof

[0043] (1) Construct an interface agent (dry powder type, YQ-MR type concrete int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com