A fuel injector for diesel engine and its method for realizing premixed combustion

A technology of fuel injectors and diesel engines, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as fuel injection hole blockage, achieve the effect of increasing air content and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

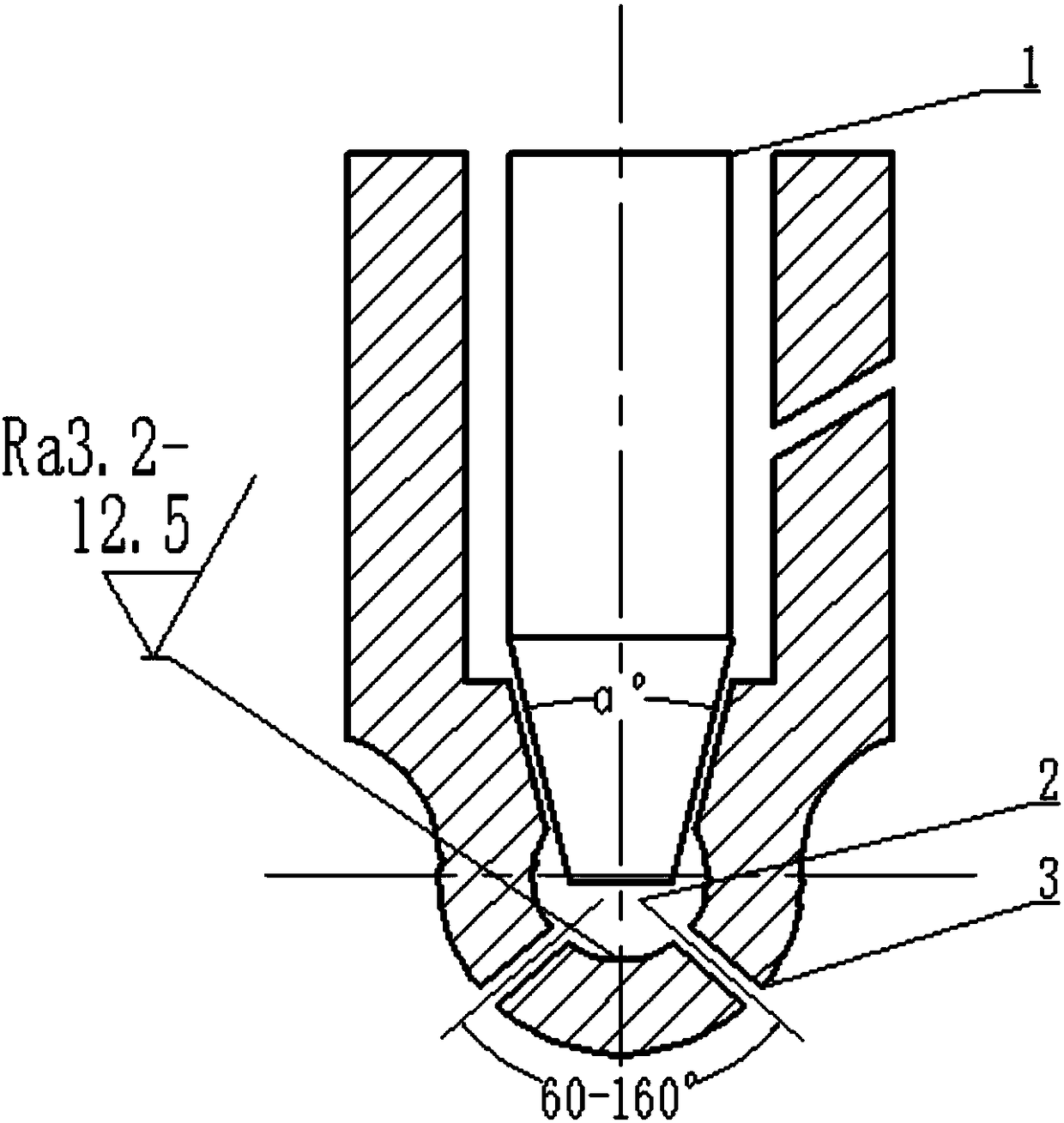

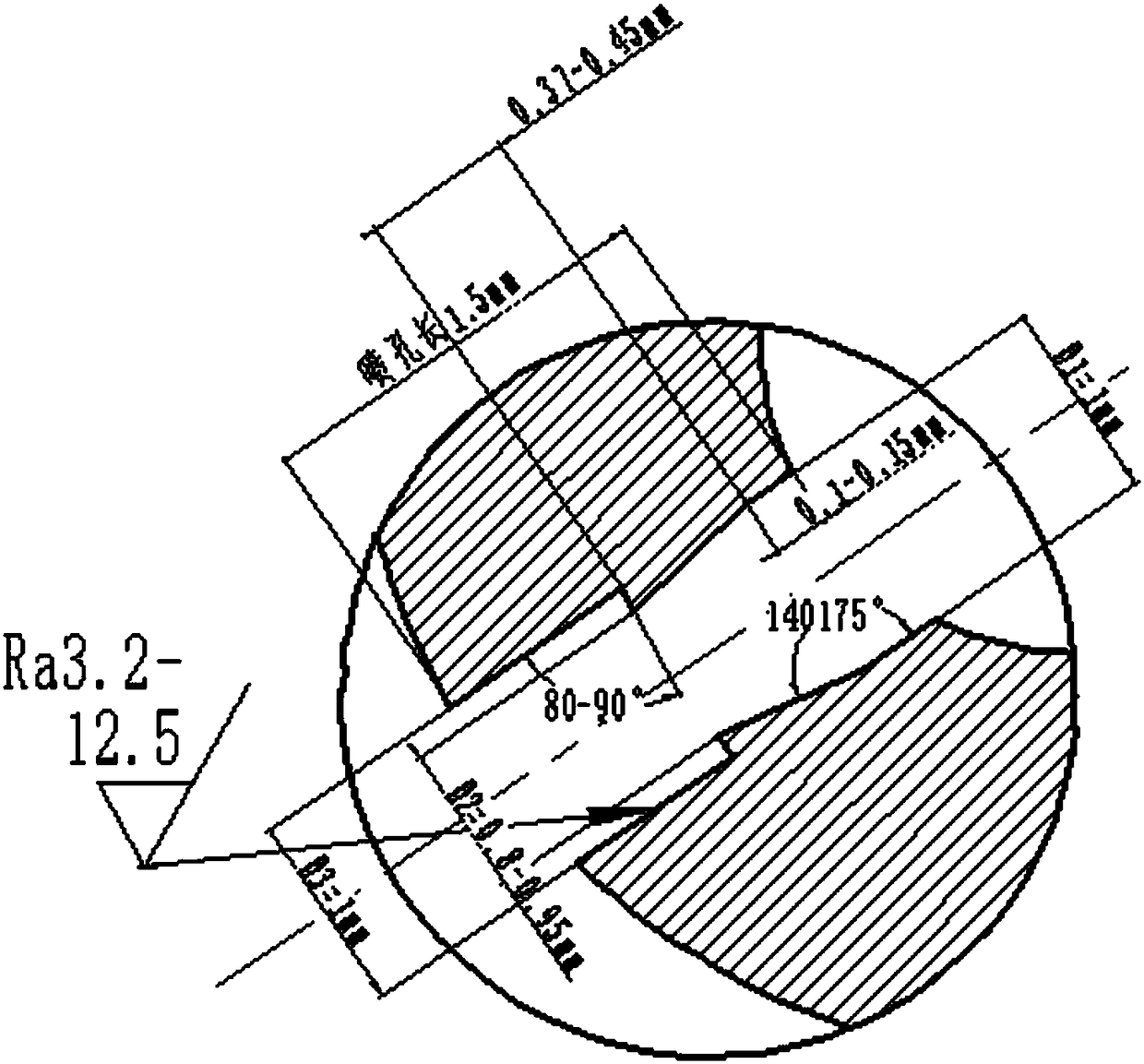

[0030] In order to further explain the technical means and methods adopted by the present invention to achieve the intended purpose of the invention, the method for realizing premixed combustion and the diesel injection method of gas-liquid two-state mixed injection proposed by the present invention will be described in conjunction with the accompanying drawings. The specific structure of the nozzle is described in detail as follows:

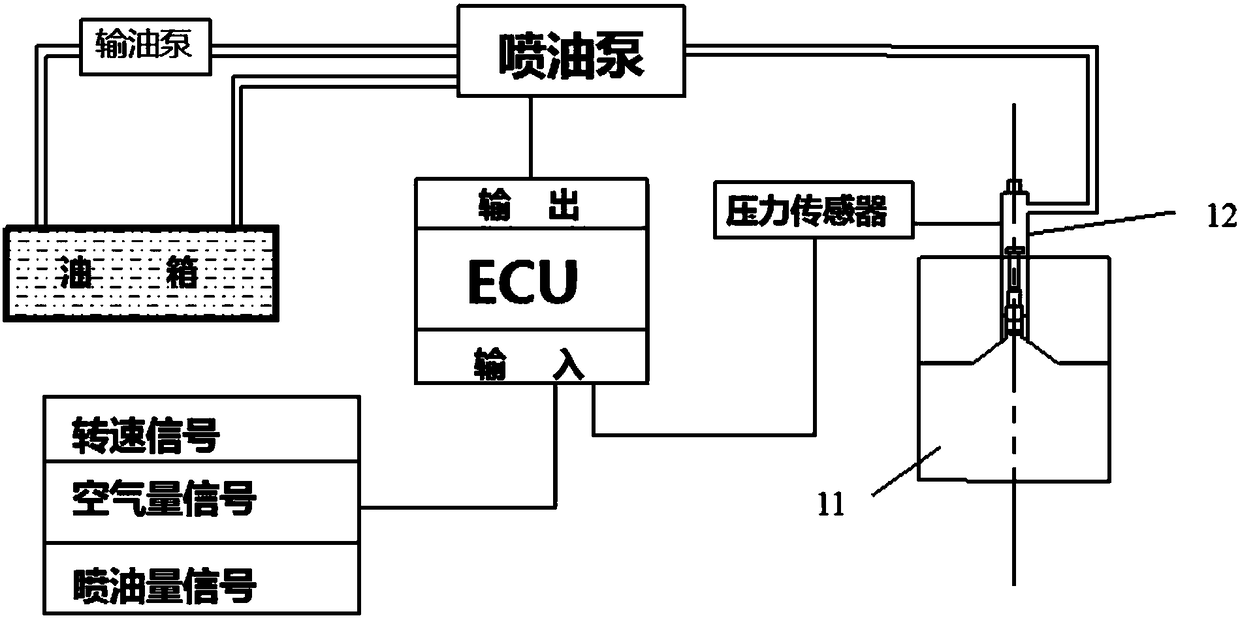

[0031] like figure 1 As shown, in the existing electronically controlled fuel injection system, the fuel injection pump is adjusted through the feedback signal of the pressure sensor and the feedback signal of the working condition of the diesel engine (including air volume signal, speed signal, fuel injection volume signal, etc.), changing The fuel injection volume of the jet in the nozzle controls the ratio of fuel and air in the gas-liquid two-phase fuel jet, so as to enhance the cavitation of the gas-liquid two-phase jet and realize the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com