Preparation method for super-amphiphobic surface of iron group metal

A super-amphiphobic surface and metal technology, which is applied to devices for coating liquids on surfaces, special surfaces, pre-treated surfaces, etc., can solve problems such as affecting chemical modification reactions, achieve simple process flow, convenient operation, and improve surface contact. corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

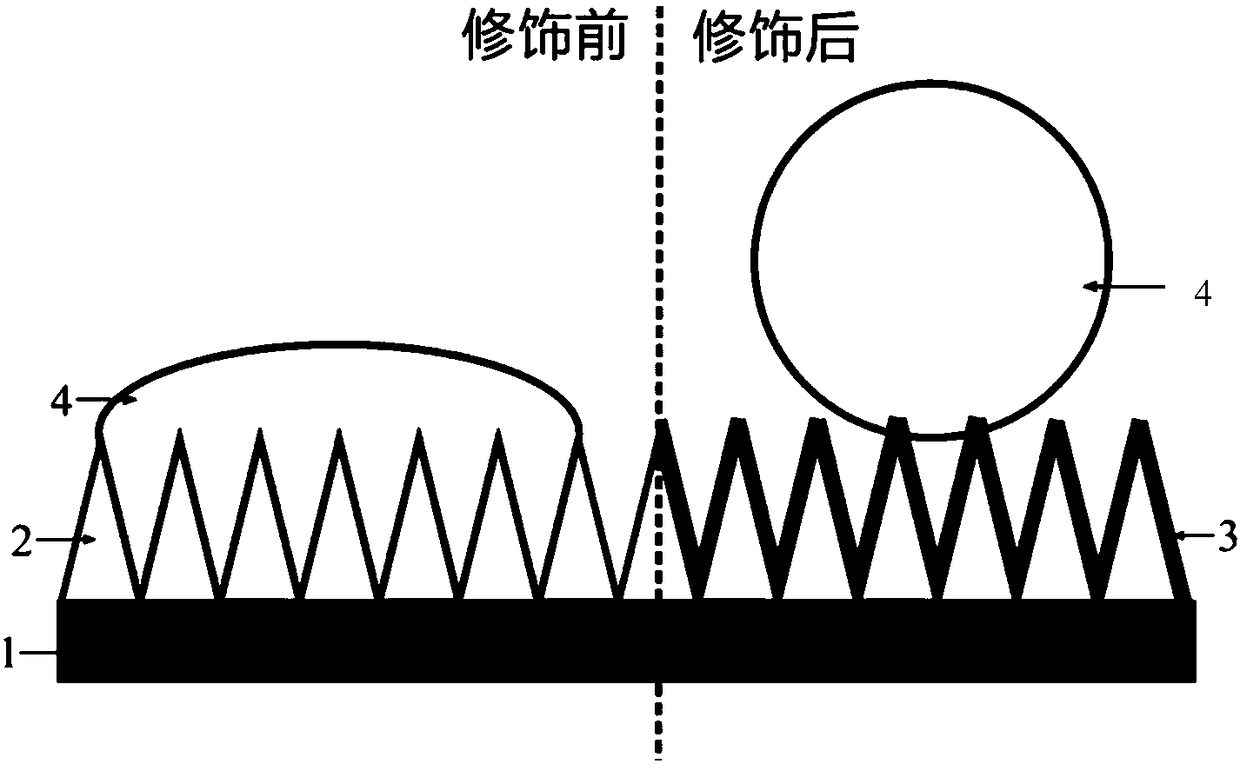

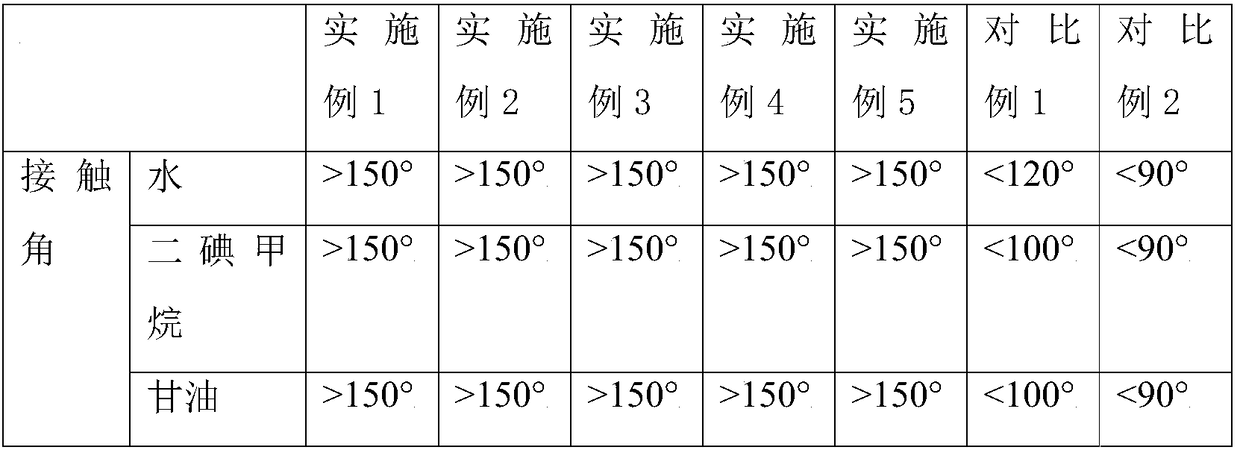

[0028] The present embodiment relates to a preparation method of a super-amphiphobic surface, such as figure 1 shown, the specific steps are as follows:

[0029] Step (1): preparation of nickel nano-needle cone array: take the substrate 1 and cut it properly, the substrate 1 is a nickel sheet, carry out degreasing, pickling and activation treatment on the surface of the substrate 1, and then place it in an electrochemical deposition solution Electroplating is carried out in the process, thereby obtaining the desired nickel nano-needle cone array;

[0030] Step (2): hydroxylation treatment of the substrate: put the nickel nano-needle cone array substrate of the above step (1) into a plasma cleaning machine, and bombard it with oxygen plasma for several seconds, so that the surface is hydroxylated;

[0031] Step (3): chemical modification of fluorosilane: put the hydroxylated substrate in the above step (2) into the prepared alcohol solution containing 1% volume fraction of per...

Embodiment 2

[0034] The present embodiment relates to a preparation method of a super-amphiphobic surface, and the specific steps are as follows:

[0035] Step (1): preparation of nickel nano-needle cone array: take the base material and cut it appropriately, the base material is a nickel sheet, carry out degreasing, pickling, and activation treatment on the surface of the base material, and then place it in an electrochemical deposition solution for electroplating , thereby obtaining the desired nickel nano-needle cone array;

[0036] Step (2): hydroxylation treatment of the substrate: put the nickel nano-needle cone array substrate of the above step (1) into a plasma cleaning machine, and bombard it with a nitrogen-oxygen mixed gas plasma for several seconds, so that the surface is hydroxylated;

[0037] Step (3): chemical modification of fluorosilane: put the hydroxylated substrate in the above step (2) into the prepared alcohol solution containing 15% volume fraction of perfluorooctylt...

Embodiment 3

[0040] The present embodiment relates to a preparation method of a super-amphiphobic surface, and the specific steps are as follows:

[0041] Step (1): preparation of nickel nano-needle cone array: take the base material and cut it appropriately, the base material is a nickel sheet, carry out degreasing, pickling, and activation treatment on the surface of the base material, and then place it in an electrochemical deposition solution for electroplating , thereby obtaining the desired nickel nano-needle cone array;

[0042] Step (2): Hydroxylation treatment of the substrate: put the nickel nano-needle cone array substrate of the above step (1) into the tabby reagent and the mixed reagent of ammonia and hydrogen peroxide to carry out ultrasonic treatment on the surface, so that the surface is hydroxylated;

[0043] Step (3): chemical modification of fluorosilane: put the hydroxylated substrate in the above step (2) into the prepared alcohol solution containing 20% volume fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com