Totally-smooth screw rotor

A screw and smooth technology, applied in the field of dry twin-screw vacuum pump, can solve the problems of poor sealing performance, large gas leakage, easy deformation, etc., to improve the ultimate vacuum degree and pumping speed, improve comprehensive performance, improve sealing performance and mechanics performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

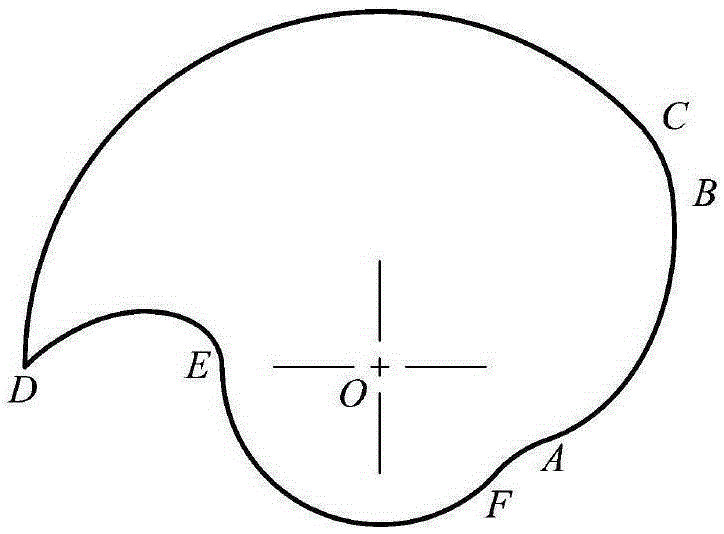

[0022] Such as figure 1 As shown, the connection point D between the addendum arc CD and the cycloid DE of the existing screw rotor end surface profile line is a rough point, that is, a sharp point.

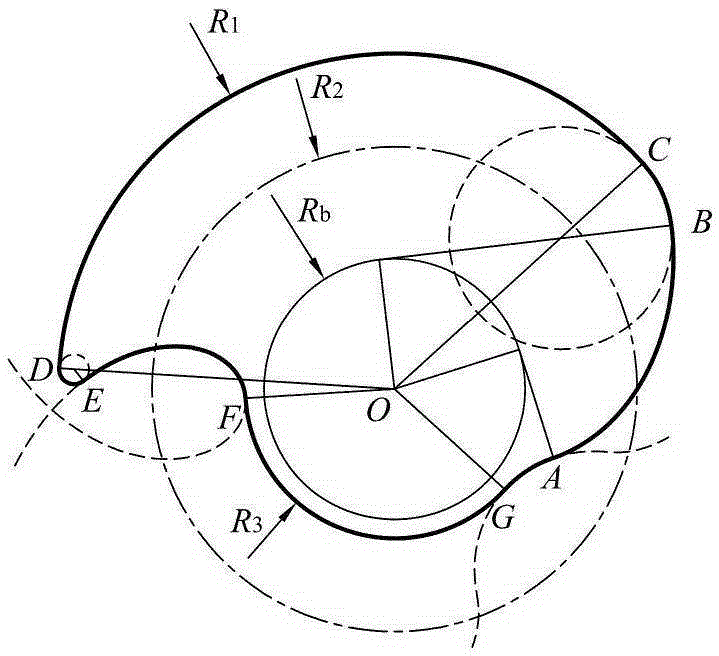

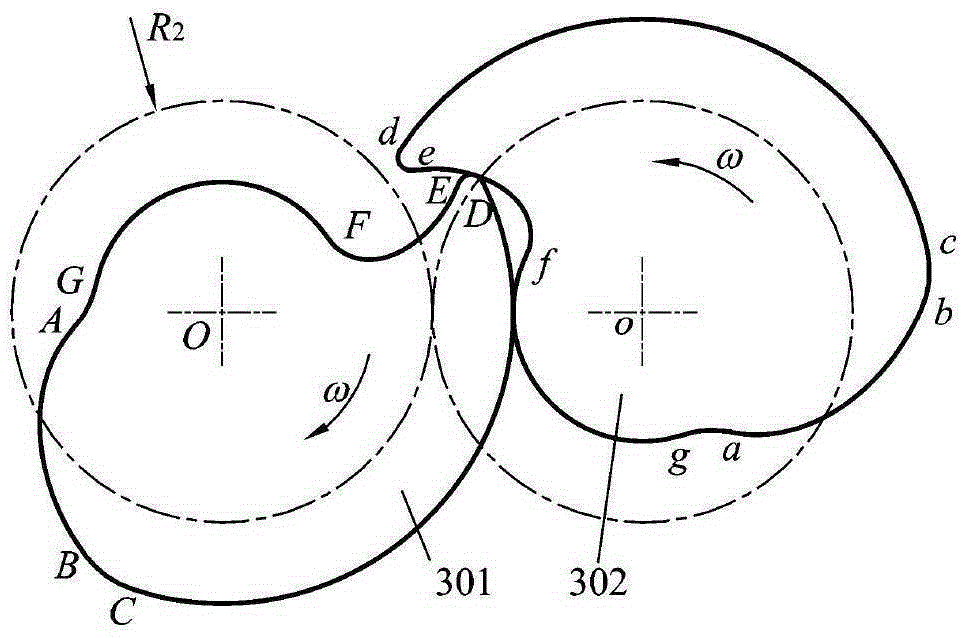

[0023] Such as figure 2 As shown, the proposed fully smooth screw rotor end surface profile is composed of 7 curves, which are: circular involute AB, circular arc BC, addendum circular arc CD, circular arc DE, equidistant cycloid Curve EF, dedendum arc FG, and cycloidal equidistant curve GA; use a segment of circular arc DE and a segment of cycloidal equidistant curve EF that are conjugated to each other to connect the dedendum arc CD and dedendum arc FG Smooth connection, using the equidistant curve GA of the cycloid to smoothly connect the dedendum arc FG and the circular involute AB, and using the circular arc BC to smoothly connect the circular invo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com