Method of etching grating groove by rotating etching angle

A technology of grating grooves and angles, applied in diffraction gratings, optics, optical components, etc., can solve the problem that the processing method is not suitable, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

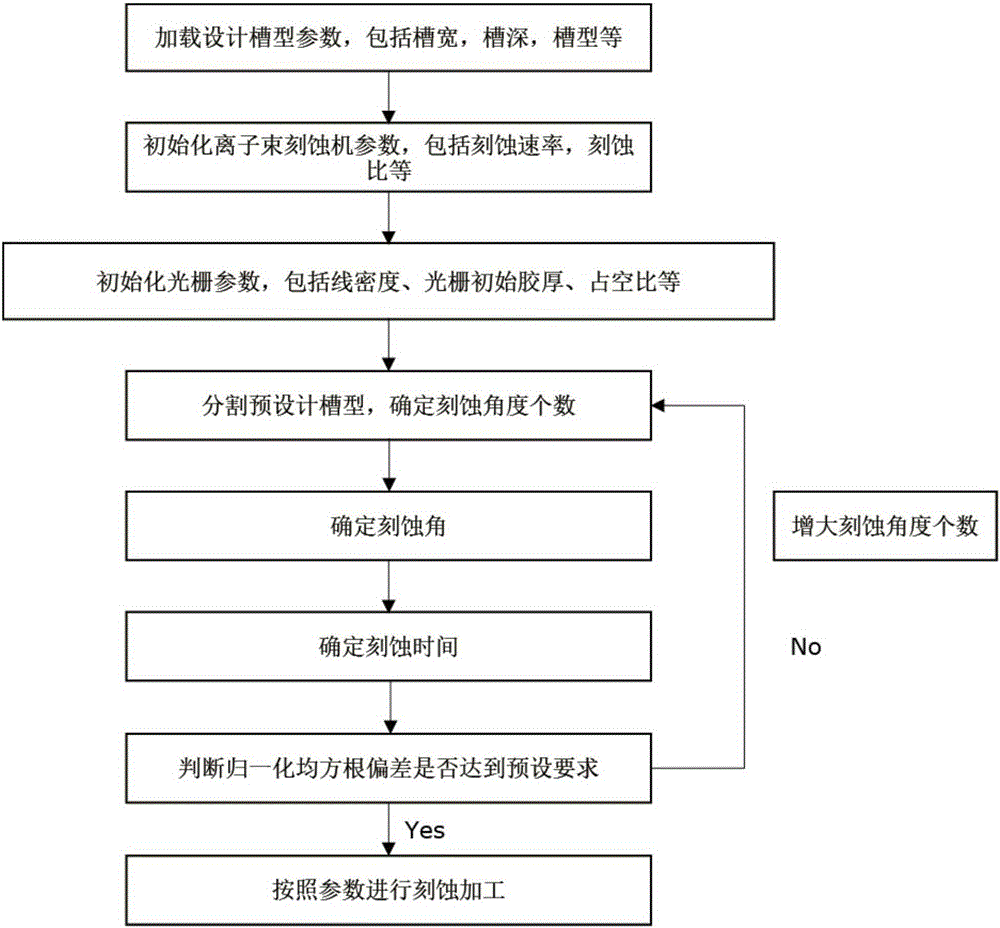

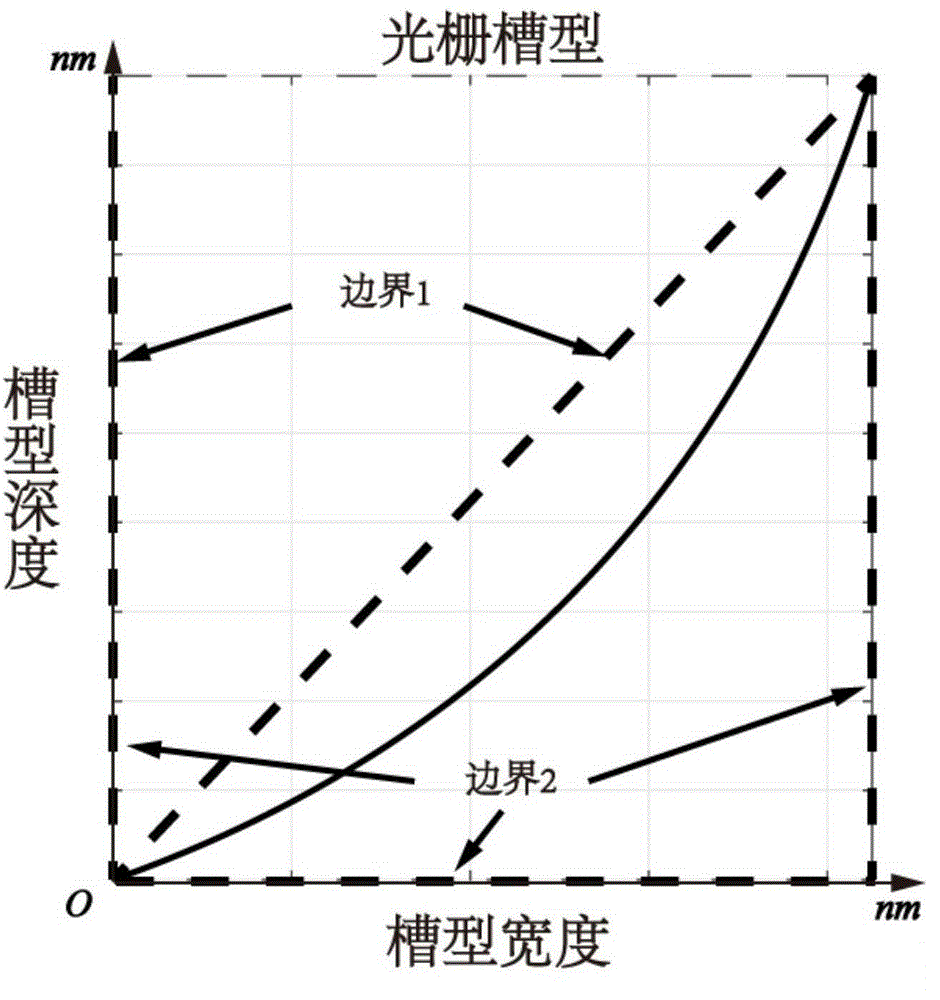

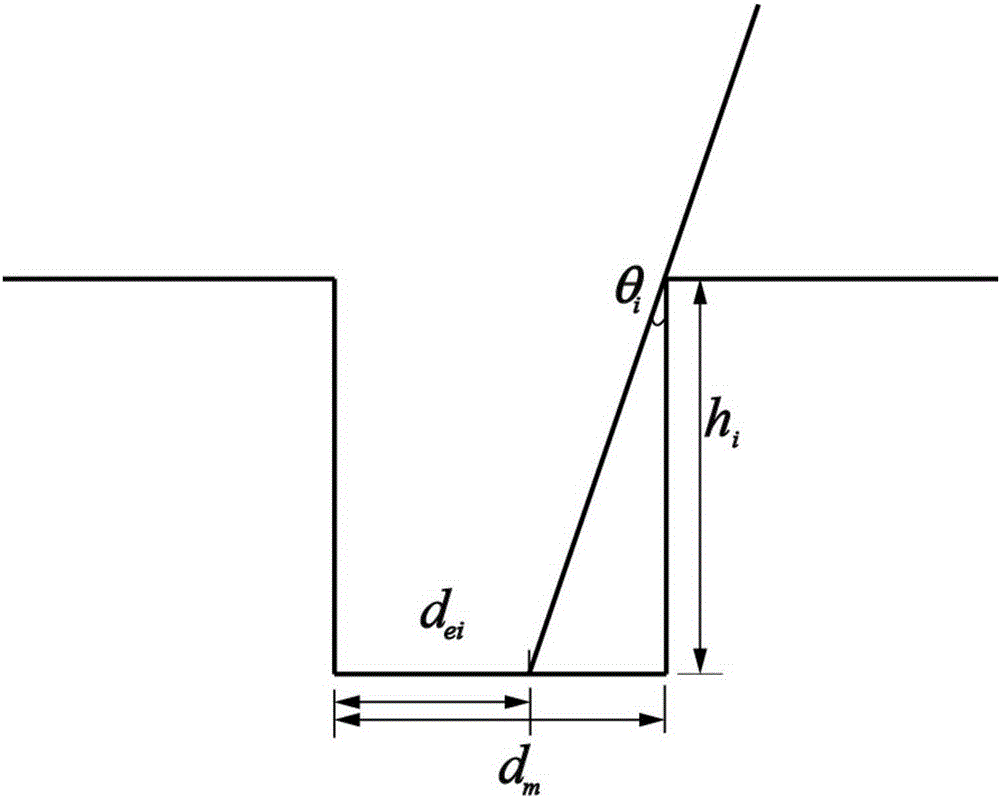

[0047] Before the specific embodiment, the idea of this method is introduced: relying on the blocking effect of the photoresist at a certain etching angle, the etched area at the bottom of the groove changes with the etching angle. By controlling the etched time under the corner, that is, controlling the etched depth of the groove bottom, a certain groove shape can be obtained.

[0048] Given some preconditions of this method, in the actual etching process, those in the related field should know that the two variables most related to the etching groove type are the etching angle and the etching rate. The etching angle determines the effective etching area of the bottom of the etched groove each time, and the etching rate determines the depth of the bottom of the etched groove under a certain etching angle and a certain etching time.

[0049] Simplify the relationship between etching rate and etching angle under certain conditions:

[0050] E. r =E r0 cosθ,

[0051] E in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com