Semiconductor structure and formation method therefor

A technology of semiconductor and interconnect structure, applied in the direction of semiconductor device, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of unstable electrical performance and poor reliability of through-silicon vias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] As described in the background art, the through silicon vias formed in the prior art have poor reliability and unstable electrical properties.

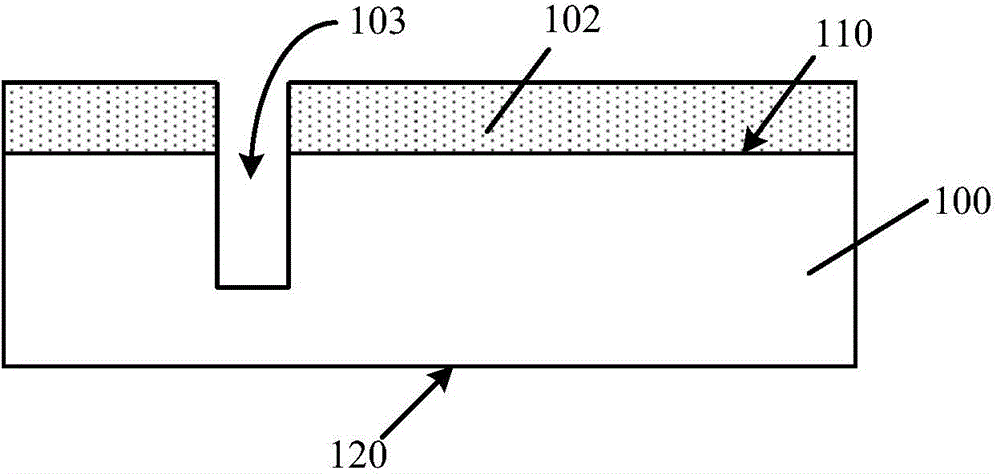

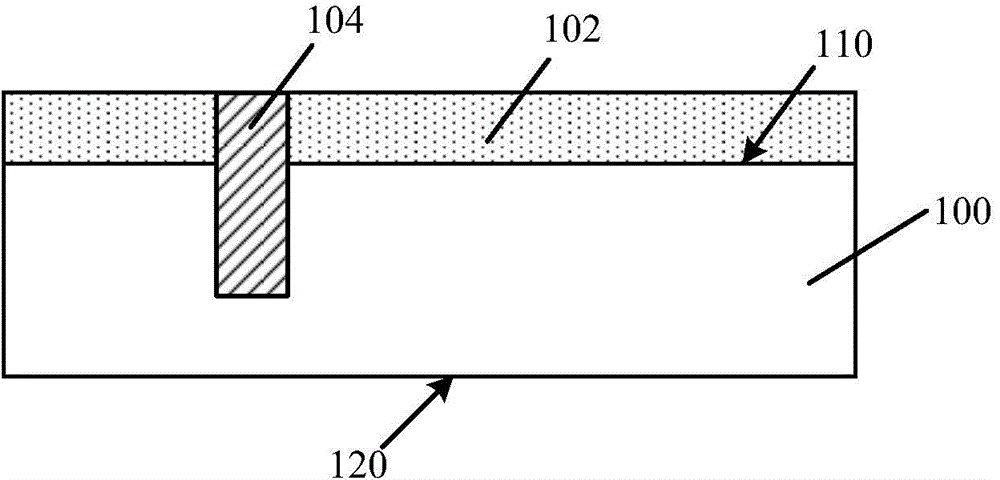

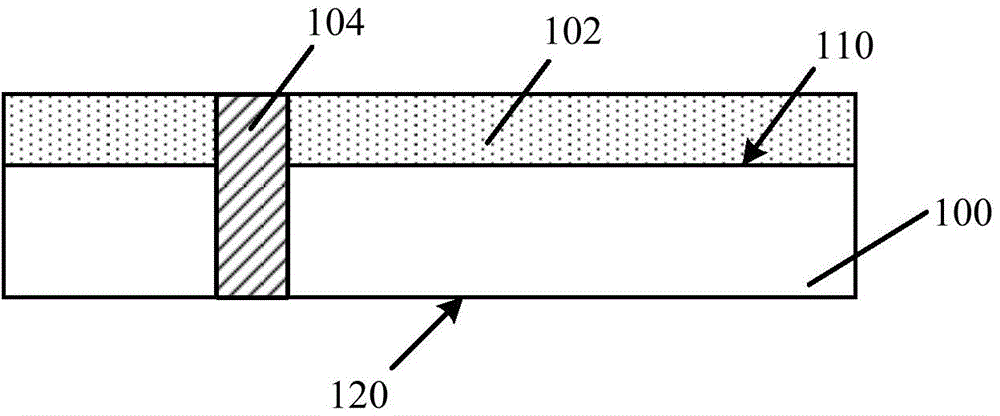

[0040] After research, please continue to refer to Figure 1 to Figure 3 The material of the conductive plug 104 formed in the through hole 103 is metal, such as copper, and the semiconductor substrate 100 is usually a silicon substrate. Due to the difference in thermal expansion coefficient between the metal material and the silicon material, when the conductive When the plug 104 is heated or cooled in the process, there will be a difference in the volume change between the conductive plug 104 and the semiconductor substrate 100, resulting in a gap between the conductive plug 104 and the semiconductor substrate 100 in contact. stress. Moreover, since the conductive plug 104 is used to form a through silicon via structure, the conductive plug 104 needs to penetrate the semiconductor substrate 100 after the second surface 120 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com