Interconnect structure and method of forming the same

A technology of interconnection structure and plasma, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as poor smoothness, affecting the shape of through holes, and affecting the performance of conductive plugs, etc., to achieve improved Effects of smoothness, improved bond strength, and reduced dents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

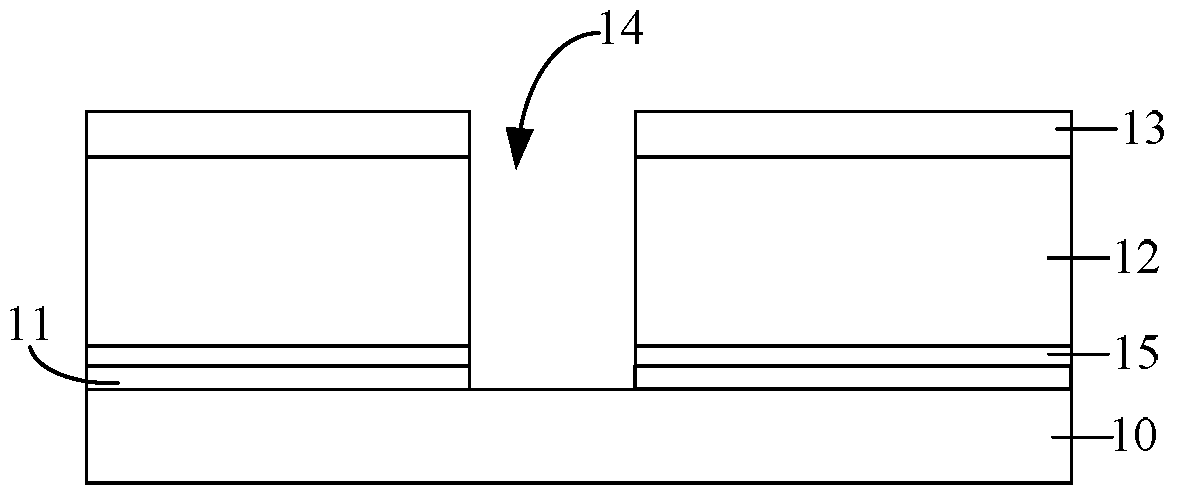

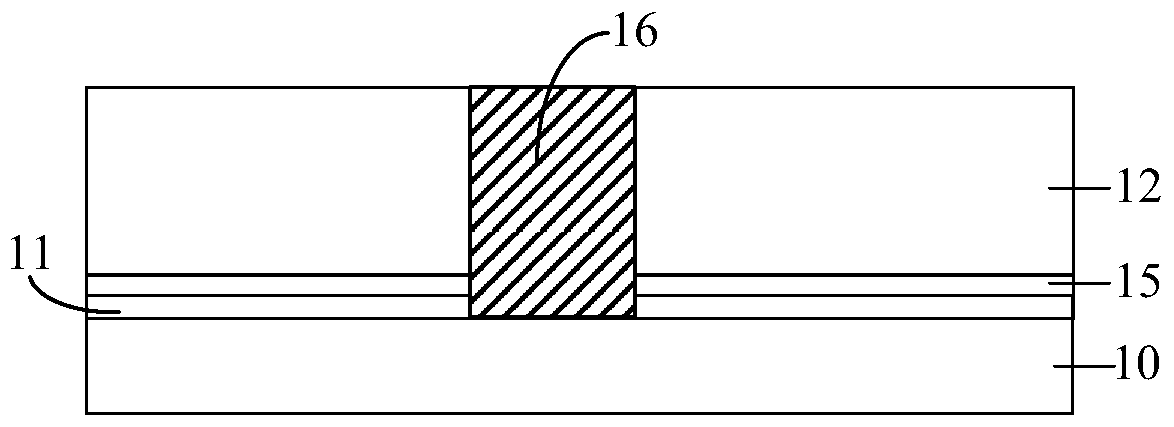

[0054] As mentioned in the background, in the interconnection structure of the prior art, the smoothness of the sidewall of the through hole is poor, which affects the shape of the through hole, and further affects the performance of the interconnection structure.

[0055] Analyzing the reason, in the wet cleaning process after etching the insulating layer, adhesion layer and dielectric layer to form the through hole, the consumption rate of the existing adhesion layer is lower than the consumption rate of the dielectric layer, so the formation of In addition, compared with the technical scheme of directly forming a dielectric layer on the substrate, forming an adhesion layer between the substrate and the dielectric layer can improve the bonding strength of the substrate and the dielectric layer, but in the wet cleaning step, The cleaning solution will still penetrate into the bonding interface of the substrate, the plasma-enhanced silicon oxide adhesion layer and the dielectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com