Connection device of solar photovoltaic panel assembly and production method of connection device

A technology of solar photovoltaic panels and connection devices, which is applied to the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., which can solve the problems of low possibility of integrated support, difficult production, inconvenient installation and disassembly, etc. The effect of reducing production accuracy and defective rate, reducing cost and processing difficulty, and ensuring strength and load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

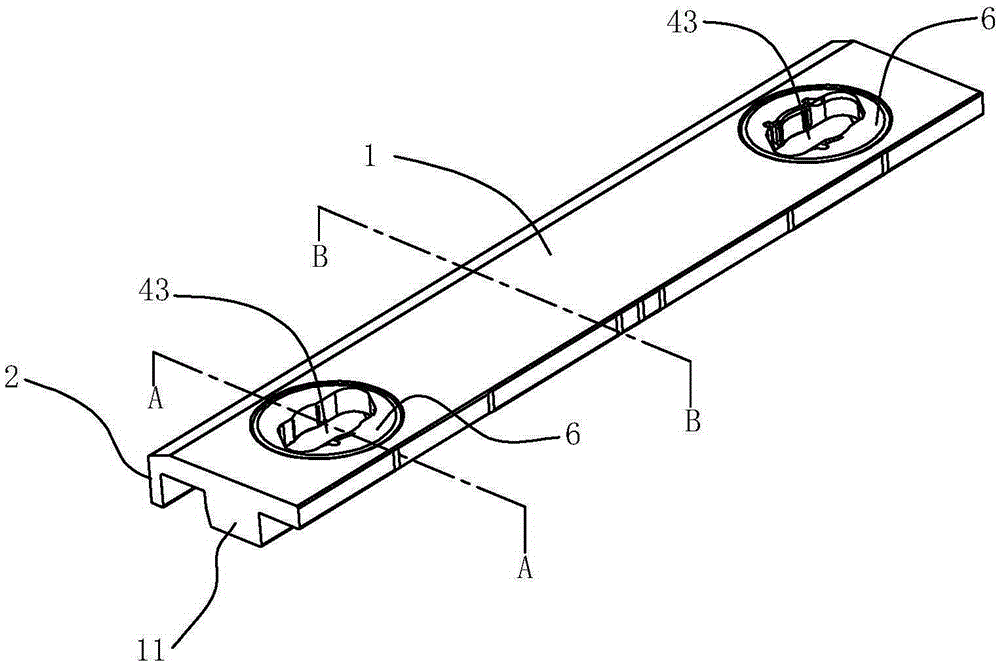

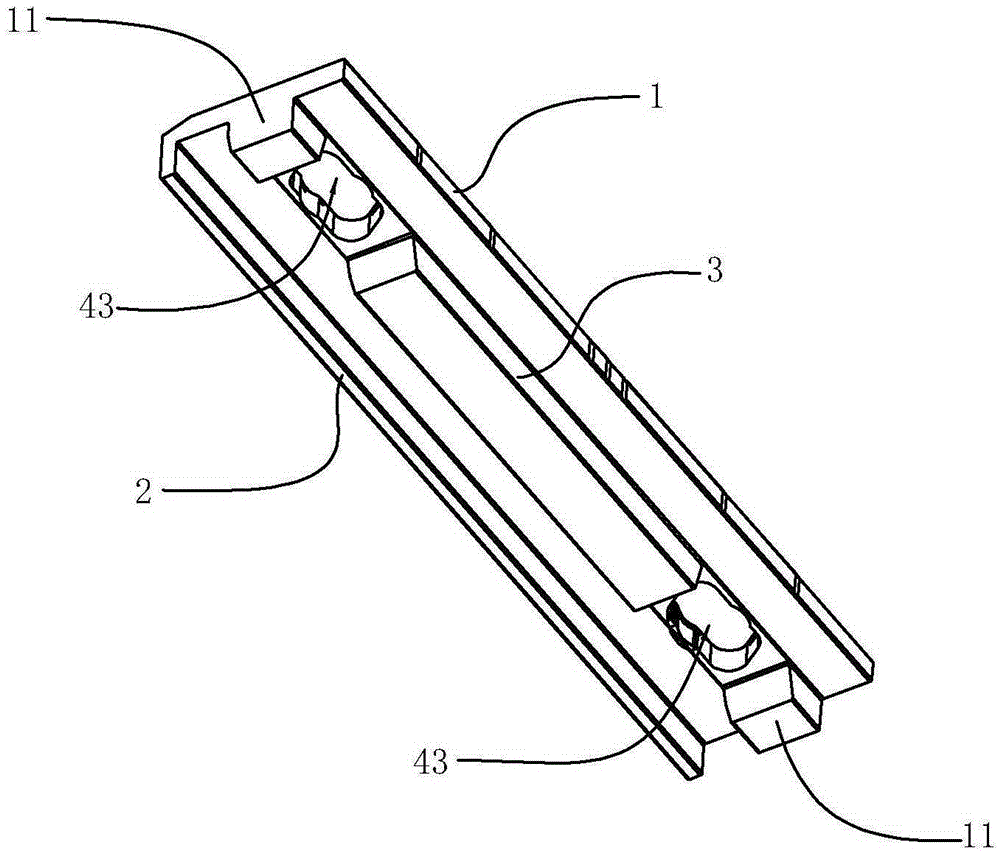

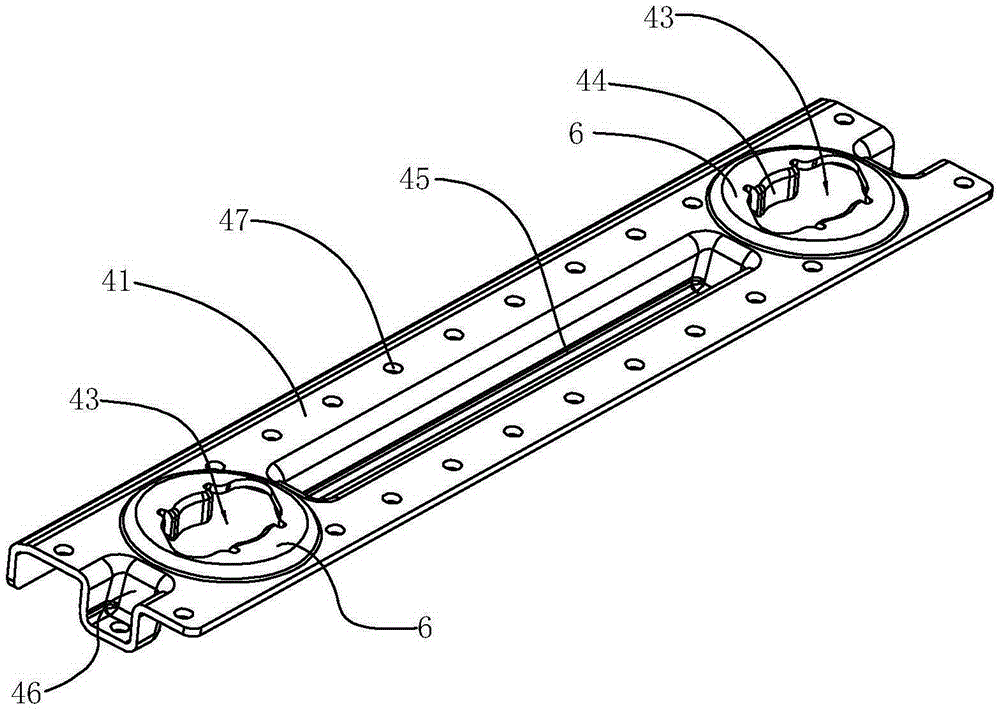

[0029] Such as Figure 1-6 As shown, the connecting device of the solar photovoltaic panel assembly according to the embodiment of the present invention is a strip-shaped part, including a strip-shaped body 1, and a side of the body 1 extending along its length and perpendicular to the body 1 On the side 2 of the body 1, on the lower surface of the body 1, that is, on the surface on the same side as the extension direction of the body 1 and the side 2, there is a reinforcing rib 3 extending in the same direction as the side 2, and the reinforcing rib 3 extends along the body 1 extending in the length direction.

[0030] The body 1 includes a conductive substrate 4 located inside, and an injection molding layer 5 surrounding the conductive substrate 4 . The shape of the conductive substrate 4 also includes a body 41 and a side 42 on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com