Device for controlling control valve of construction machine, method for controlling same, and method for controlling discharge flow rate of hydraulic pump

A technology for controlling engineering and hydraulic pumps, which is applied to mechanical equipment, soil movers/shovels, fluid pressure actuators, etc., can solve problems such as trembling of working equipment, increased pressure loss, and increased pressure, so as to prevent trembling, Effect of reducing pressure loss and load pressure and reducing human accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, an apparatus and method for controlling a control valve of a construction machine and a method for controlling a discharge flow rate of a hydraulic pump of a construction machine according to preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

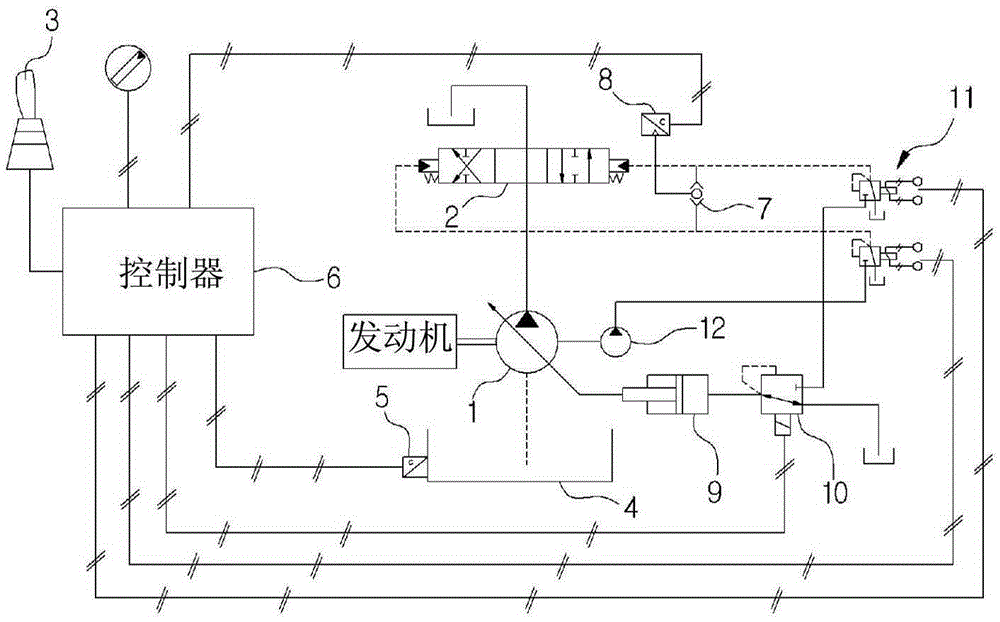

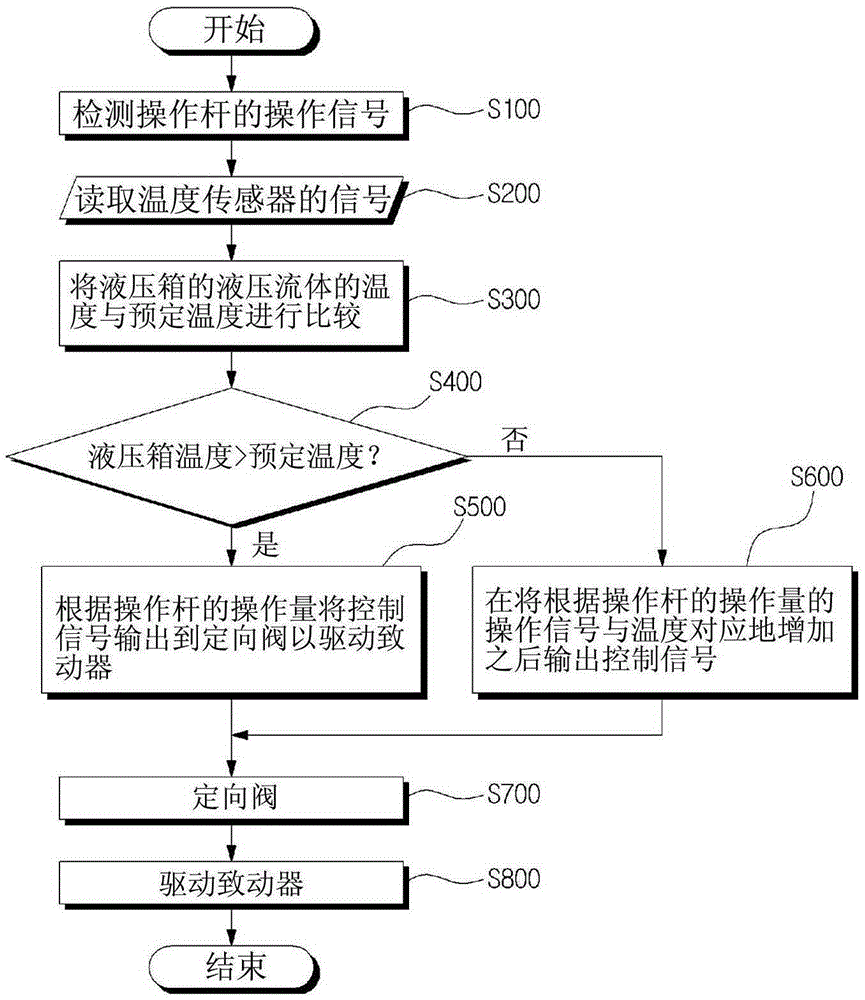

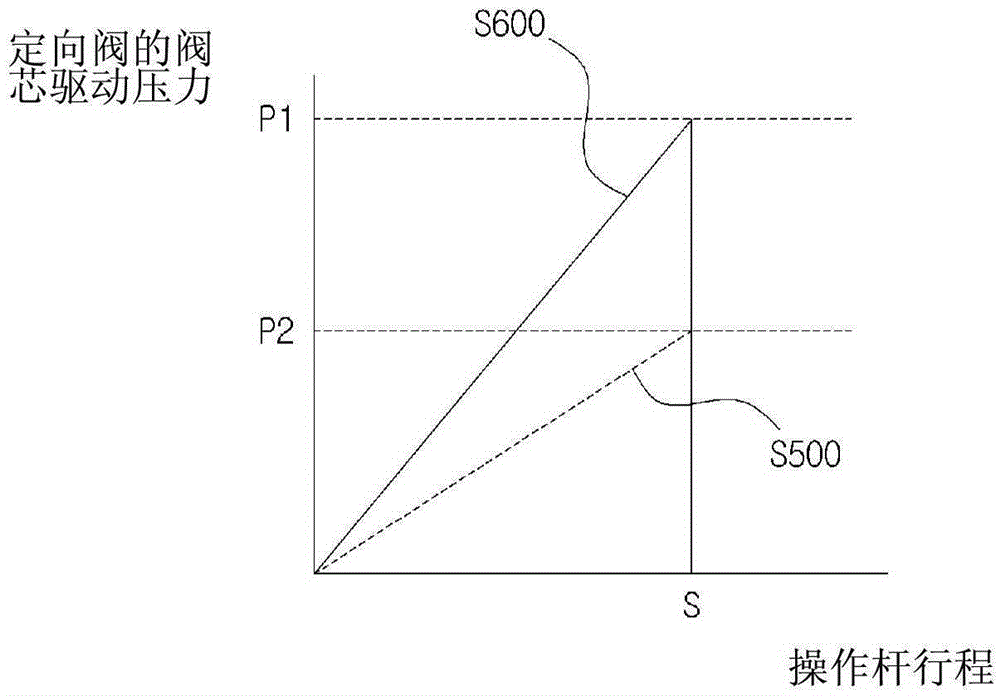

[0063] figure 1 is a hydraulic circuit diagram of an apparatus for controlling a control valve of a construction machine according to an embodiment of the present invention, figure 2 is a control algorithm diagram of a method for controlling a control valve of a construction machine according to an embodiment of the present invention, image 3 is a graph showing a relationship between a stroke of an operating rod and a spool displacement pressure of a control valve in an apparatus for controlling a control valve of construction machinery according to an embodiment of the present invention. Figure 4 is a hydraulic circuit diagram of a control devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com