Coaxial filter rod with double permeability

A permeability and coaxial technology, applied in the direction of e-liquid filter, application, tobacco, etc., can solve the problem that the flue gas temperature and flue gas flow path are not adjusted, affect the use of filter rods in cigarettes, and do not mention the tow specifications, etc. It can improve the sensory quality, reduce the tar content and CO release of cigarettes, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

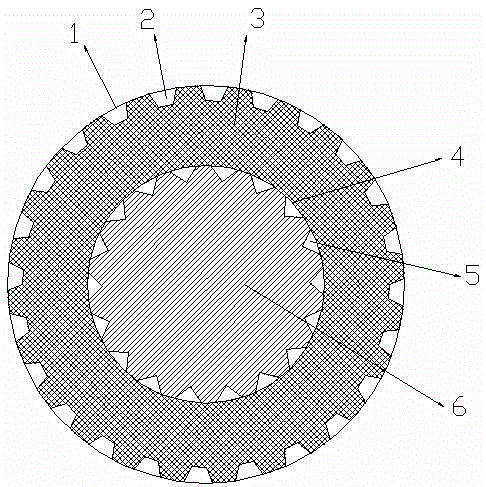

[0023] The grooved coaxial core filter rod prepared by the special specification acetate fiber tow adopted in the present invention, such as figure 1 As shown, the outer diameter of the prepared filter rod is 7.5-7.7mm, the inner core diameter is 4.7-5.0mm, the length of the filter rod is 84-120mm, and the pressure drop of the filter rod is 2800-4000Pa.

[0024] Special specification tows are used, the inner core tow is 11Y / 15000, and the outer core tow is 6.7Y / 17000; other raw and auxiliary materials are the same, and the same process is used to prepare grooved coaxial core filter rods. The inner core is full, the filling amount of the outer filter element is moderate, the inner and outer grooves of the filter rod are clear, the pressure drop difference of the inner core is 3 / 4 of the pressure drop of the outer core, the effect of reducing cigarette tar and CO is good, and the cigarette smoke Optimal sensory quality. In addition, the hardness of the inner core and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com