Preparation method of tobacco lotus fibers and moisture preserving filter tip containing same

A technology of lotus fiber and filter rod, which is applied in the field of preparation of cigarette filter rods, can solve the problems of less chemical odor, lotus fiber cannot be used in cigarettes, affects the taste of cigarettes, etc., and achieves increased comfort and moisturizing, and smoke interception. Good effect, the effect of improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

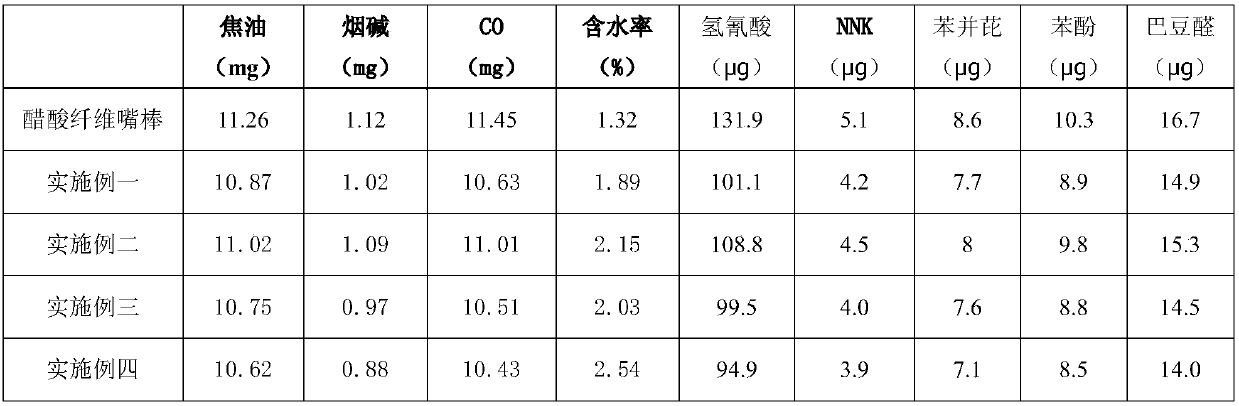

Examples

Embodiment 1

[0023] Embodiment 1, the specific preparation steps of the lotus fiber for tobacco are as follows:

[0024] (1) Select fresh lotus petiole to remove dirt and impurities on the surface, cut the lotus petiole into raw material slag, extrude and grind the raw material slag to form a slurry raw material, add 1% cellulase solution to the slurry raw material, and heat to Stirring and reacting at 50°C for 2 hours to obtain lotus fiber pulp; wherein the concentration of the cellulase solution is 0.5-1%;

[0025] (2) immerse the lotus fiber slurry in the step (1) in a NaOH aqueous solution with a concentration of 20%, and mix and stir evenly to obtain a mixture;

[0026] (3) Put the mixture into a cooking tank, heat it with steam and cook it, and keep it at 120°C and a pressure of 1.0Mpa for 1.5 hours, and then separate the solid phase from the cooking tank through a sieve to obtain crude fiber ;

[0027] (4) Adopt the NMMO aqueous solution that volume fraction is 15~20% to make solv...

Embodiment 2

[0033] Embodiment 2: The specific preparation steps of the lotus fiber for tobacco are the same as the lotus fiber for tobacco in Example 1, and the lotus fiber for tobacco is compounded with acetate fiber according to the ratio of 20% of the weight of the filter core to prepare a filter element. The specific preparation process is as follows: the lotus fibers for cigarettes are sequentially bundled and crimped according to the existing preparation process of cellulose acetate tows to make lotus fiber tows, which are then glued, shaped, and cut to form lotus fiber filter core segments, and Composite wrapping molding paper with cellulose acetate tow section, and prepare moisturizing filter rod B containing lotus fiber for tobacco.

Embodiment 3

[0034] Embodiment three, the specific preparation steps of the lotus fiber for tobacco are as follows:

[0035](1) Select fresh lotus root to remove dirt and impurities on the surface, cut the lotus root into raw material slag, extrude and grind the raw material slag to form a slurry raw material, add 3% cellulase solution to the slurry raw material, and heat to 60°C Stirring and reacting for 2 hours to obtain lotus fiber pulp; wherein the concentration of the cellulase solution is 0.5-1%

[0036] (2) immerse the lotus fiber slurry in the step (1) in a 30% NaOH aqueous solution, and mix and stir evenly to obtain a mixture;

[0037] (3) Put the mixture into a cooking tank, heat it with steam and cook it, and keep it at 120°C and a pressure of 1.0Mpa for 1.5 hours, and then separate the solid phase from the cooking tank through a sieve to obtain crude fiber ;

[0038] (4) Adopt the NMMO aqueous solution that volume fraction is 15~20% to make solvent, add the acetic anhydride o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com