Automatic pipe cutting device for cable protection pipes

A technology of cable protection tube and tube cutting device, which is applied in metal processing and other directions, can solve the problems of poor product quality, low work efficiency, and slow cutting speed, and achieve the effect of fast cutting speed, high work efficiency and precise cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

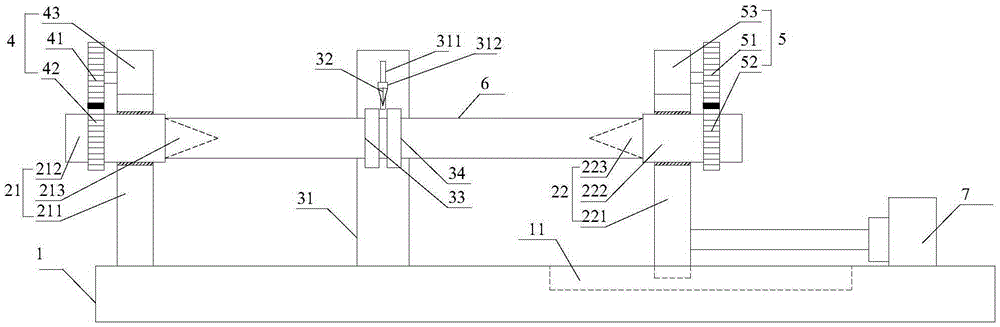

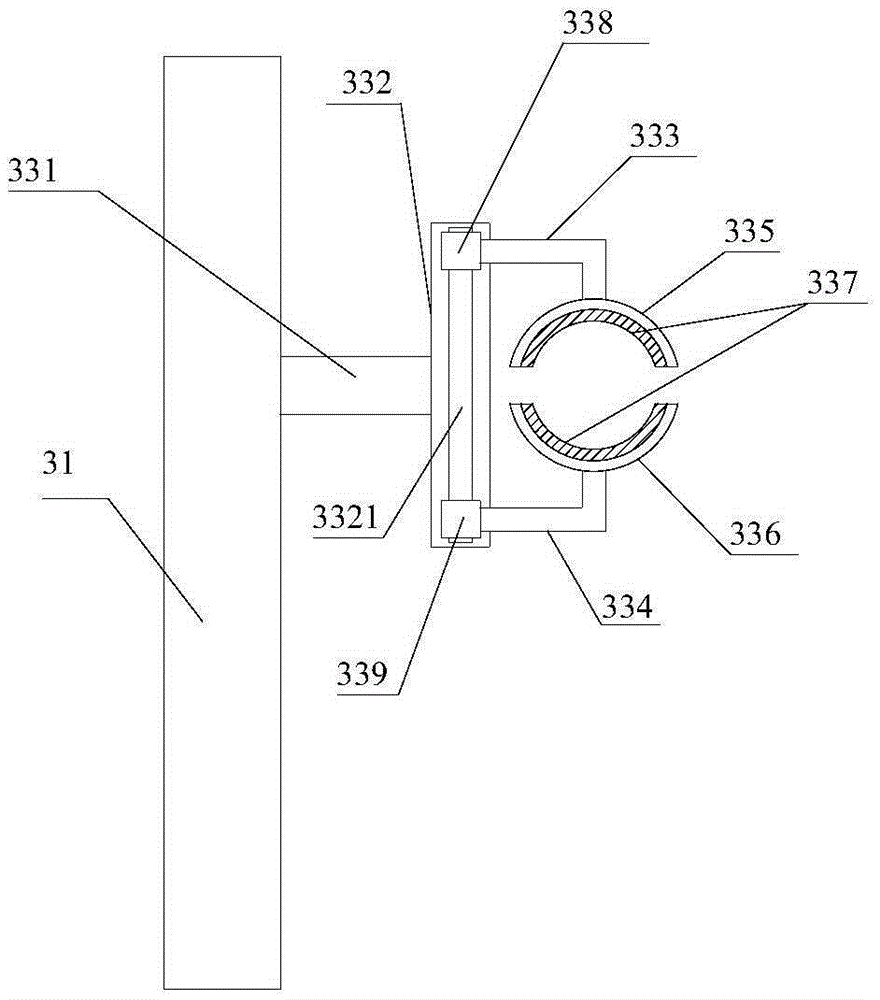

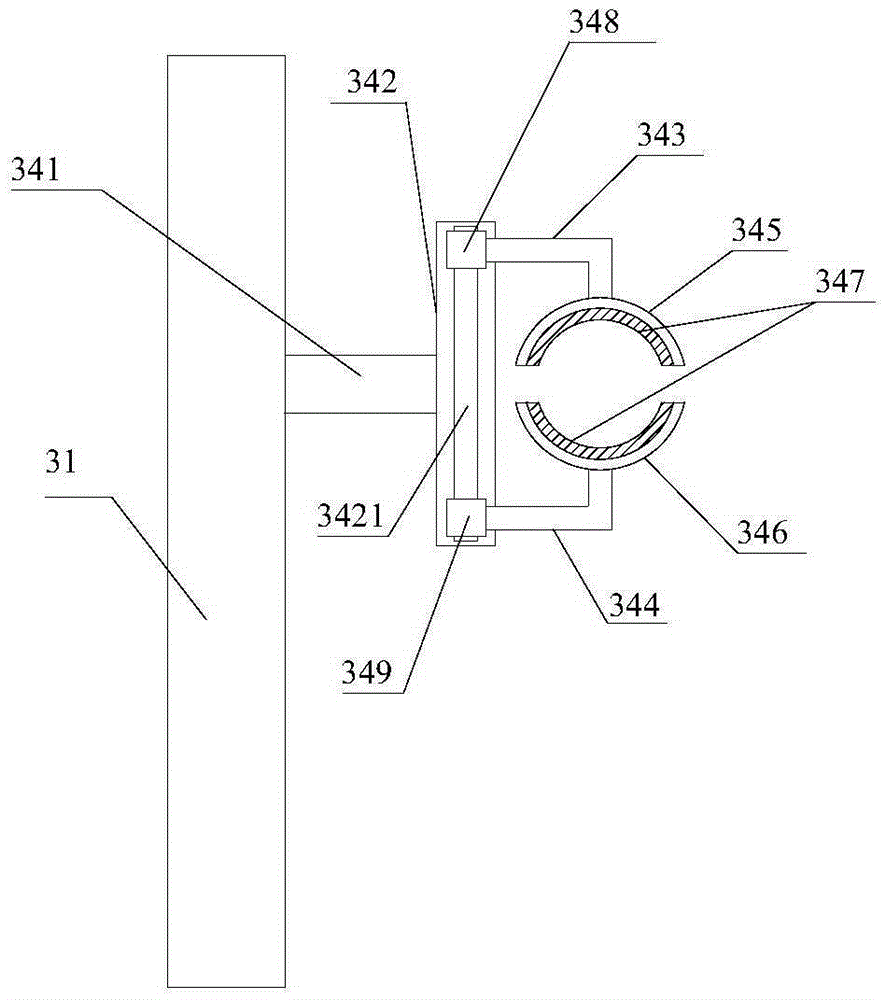

[0021] refer to figure 1 , figure 2 , image 3 , the present invention proposes an automatic pipe cutting device for cable protection pipes, including a base 1, a fixing mechanism for fixing the cable protection pipe 6, a pipe cutting mechanism for cutting the cable protection pipe 6, a first driving mechanism 4, a second driving mechanism Mechanism 5, the third driving device 7, wherein:

[0022] The fixing mechanism includes a first fixing device 21 and a second fixing device 22. The first fixing device 21 includes a first fixing frame 211 installed on the base 1, a first cylinder 212 installed on the first fixing frame 211 through a bearing, The first conical column 213 installed on the first cylinder 212, the first conical column 213 is used to fix the cable protection tube 6, the first drive mechanism 4 is connected with the first cylinder 212 for driving the first cylinder 212 Do axial rotation; the second fixing device 22 includes a second fixed frame 221 movably mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com