High-strength mold adjustment plate for injection molding machine

A high-strength, injection molding machine technology, applied in the field of adjustment platen of injection molding machine, can solve the problems of uneven force of adjustment platen, bending deformation of adjustment platen, easy to produce deformation, etc., to achieve small deformation, reduce stress concentration, and resist deformation. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

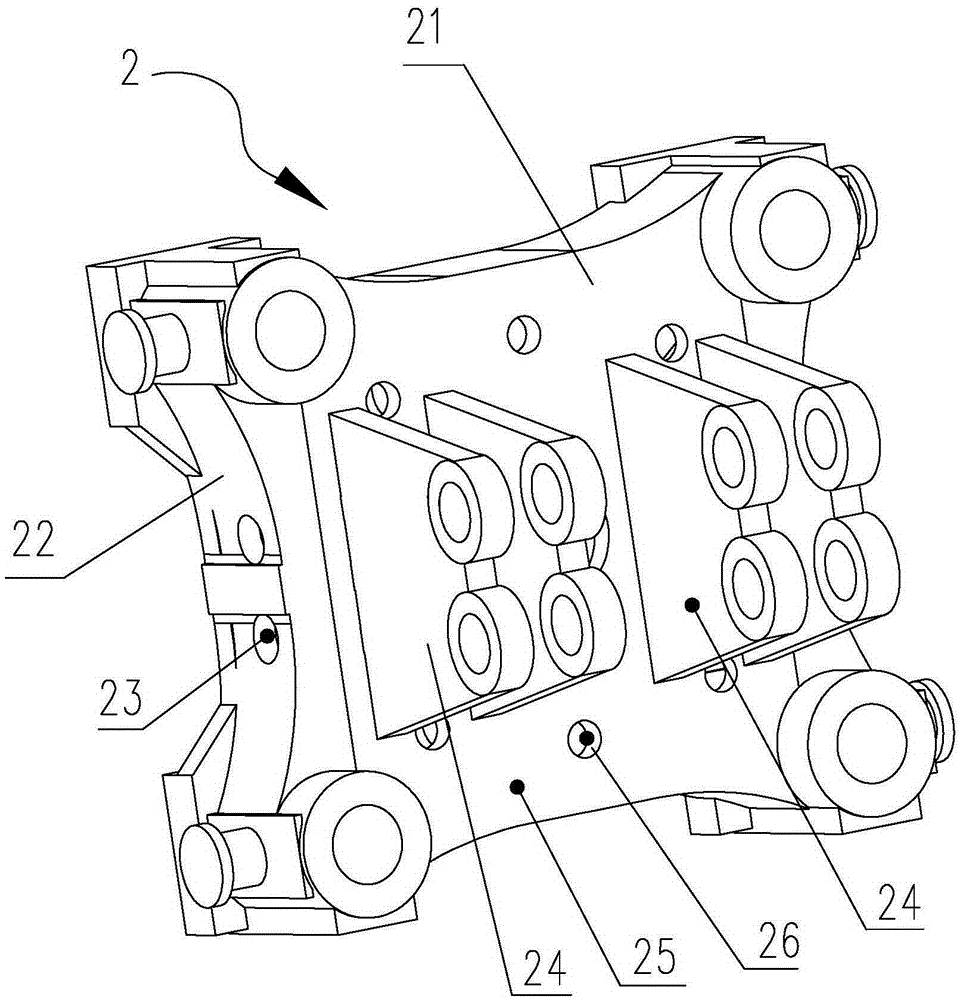

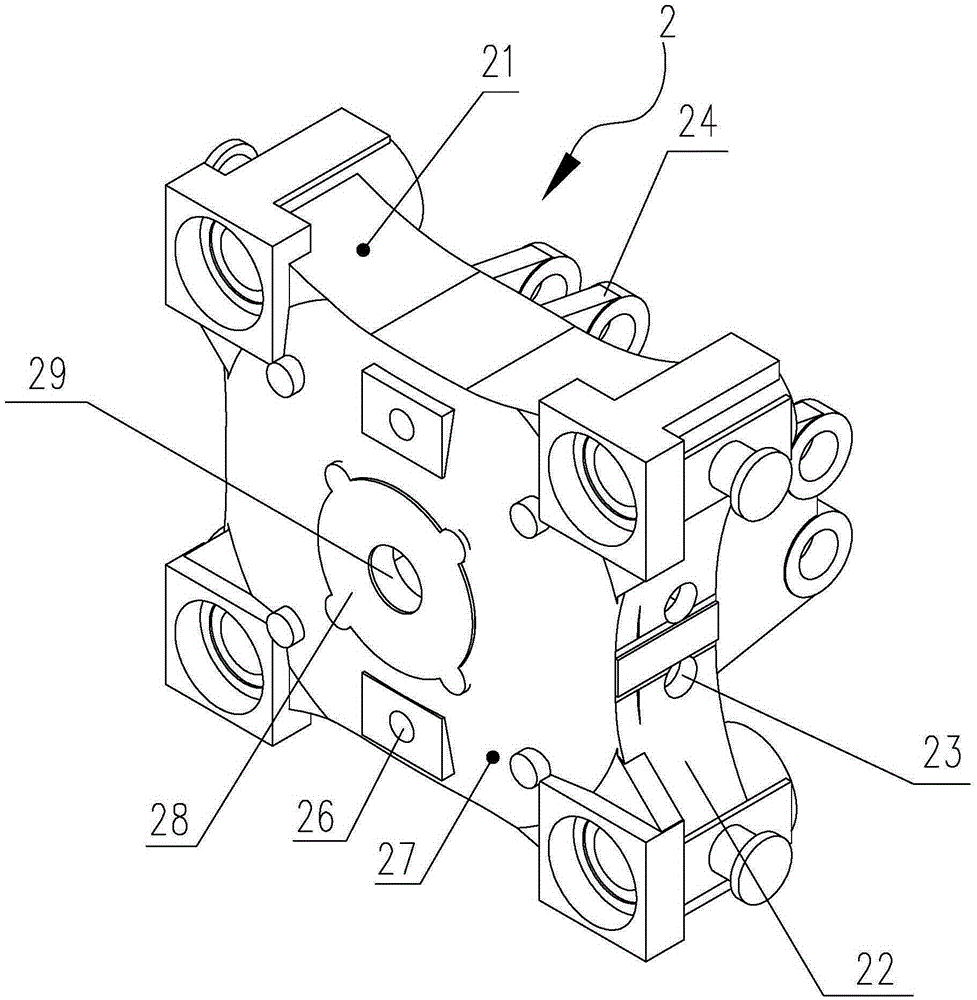

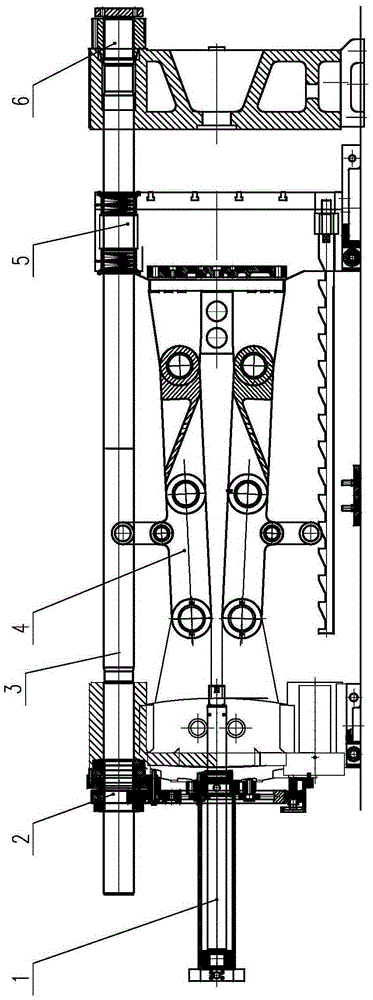

[0018] Such as figure 1 , figure 2 As shown, the high-strength adjustment template for injection molding machine of the present invention includes a template body 21, the template body 21 is a flying saucer shape, the template body 21 includes a template front 25 and a template back 27, and the surrounding sides between the template front 25 and the template back 27 The edge is connected to form the template side 22, the outer surface of at least one of the template front 25 and the template back 27 is an outwardly convex curved surface, and the template front 25 is connected with the template front 25 and is integrated with it. The conjoined connecting rod winch 24. In this embodiment, the outer surface of the template front 25 is an outwardly convex curved surface, and the conjoined connecting rod hinge seat 24 is connected to the outwardly convex curved surface of the template front 25 . The template back 27 is provided with a clamping oil cylinder installation end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com