Production method of gamma-oryzanol

A production method and technology of oryzanol, which is applied in the field of γ-oryzanol production, can solve the problems of low purity of crude γ-oryzanol, low yield of crude γ-oryzanol, unreasonable and effective procedures, etc., to shorten the time of filtration and improve the purity , good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: filter residue preparation

[0042] Extract the rice bran oil from the rice bran oil soapstock with n-hexane, the obtained rice bran oil has a solubility of 1.5-2.0% γ-oryzanol, add caustic soda for deacidification, and obtain alkaline oil residue, then add sulfuric acid, add hydrolysis to obtain black oil and refined rice oil; the black oil is esterified with methanol and sulfuric acid, and then distilled under reduced pressure at 180 degrees at 5 mmHg, and the residue obtained is the filter residue, which contains about 30% gamma-oryzanol.

Embodiment 2

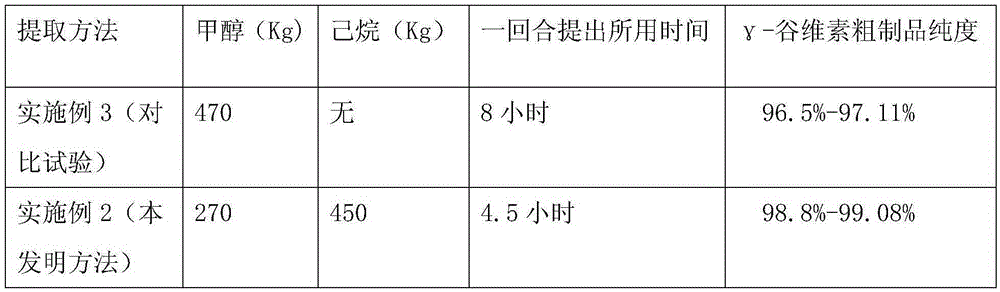

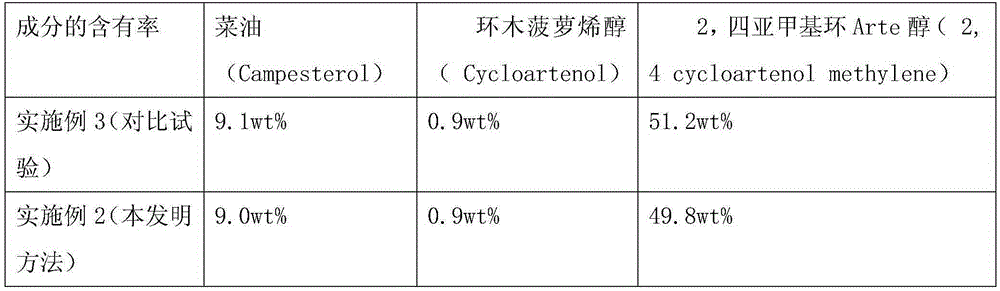

[0043] Embodiment 2: production of gamma-oryzanol crude product

[0044] 1. the filter residue 190Kg gained in embodiment 1 is poured into 2000L dissolving tank; The filter residue is alkaline, and solubility is 30% gamma-oryzanol;

[0045] ② Add 270Kg of methanol and mix, then add 300Kg of hexane and stir for about an hour; the stirring speed is 60 rpm;

[0046] ③Put in 16Kg acetic acid for neutralization, stir and reflux in the dissolving tank for 30 minutes to obtain the mixture;

[0047] ④Heat the mixture in a water bath to 50°C, heat, stir and reflux for about 30 minutes;

[0048] ⑤Continue to pour 36L of water for stirring; the stirring rate is 60 rpm, and stand for one hour after the stirring is stopped; the crude product γ-oryzanol is precipitated;

[0049] ⑥ The solution is automatically stratified, the upper layer is a hexane solution containing pigments, impure oils, and viscous substances; the lower layer is a crude product γ-oryzanol precipitate and methanol dis...

Embodiment 3

[0054] Embodiment 3: comparative test

[0055] This comparative test is actually the method used in the prior art.

[0056] 1. pour 190Kg of embodiment 1 gained filter residue into 2000L dissolving tank; Described filter residue is alkaline, contains 20-30% gamma-oryzanol;

[0057] ②Add 470Kg of methanol to mix, and circulate in a water bath at 60°C for 2 hours; cool to 40°C to separate layers, and take the upper filtrate;

[0058] ③ Add 16Kg acetic acid to the upper layer filtrate to neutralize and separate out the γ-oryzanol precipitated particles, then stir and reflux for 30 minutes;

[0059] ④Heat in a water bath to 50°C for about 30 minutes; then add 160Kg of methanol;

[0060] ⑤ Pour 36L of water into it for stirring, and let it stand for one hour after the stirring stops;

[0061] ⑥Filter for 5 hours;

[0062] ⑦ Collect the precipitated particles of γ-oryzanol and dry them at low temperature at 40°C to obtain crude γ-oryzanol; the methanol waste liquid is recovered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com