Prestressed pipe pile construction method based on building information modeling (BIM) and prestressed pipe pile

A technology of prestressed pipe piles and construction methods, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of environmental pollution of surrounding roads, different construction methods, and long construction processes, etc., to achieve increased shear resistance, Ensure the construction period and shorten the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

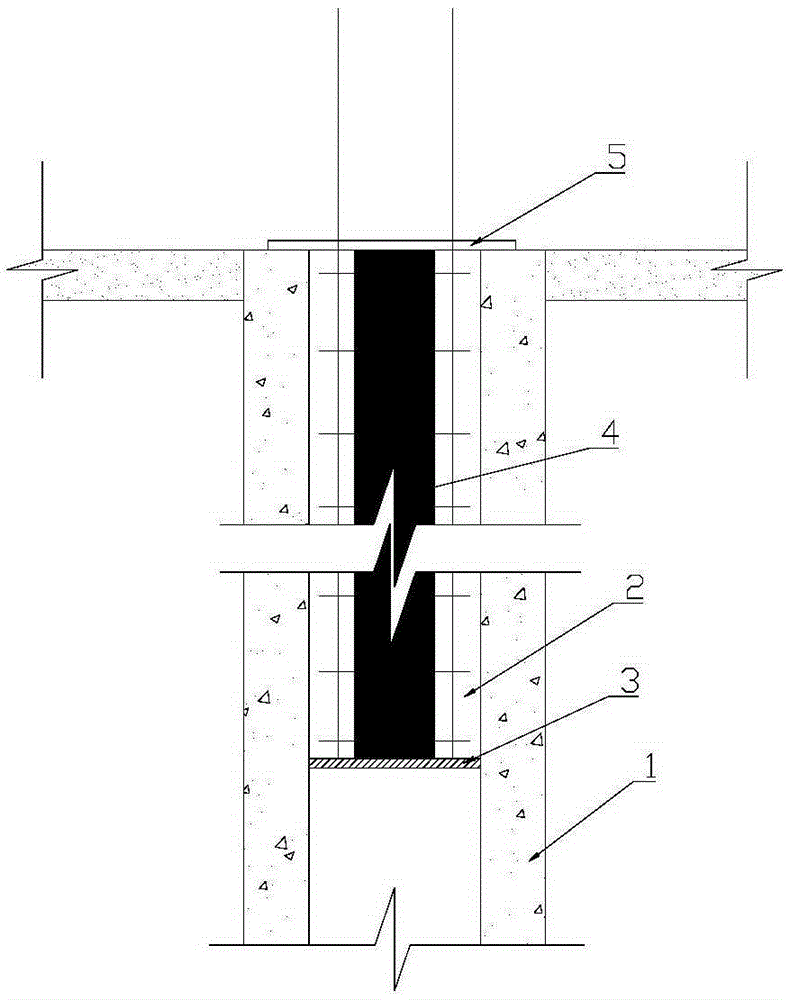

[0033] The present invention provides a construction method for prestressed pipe piles based on BIM. Before implementing the present invention, the geological conditions of the construction must be analyzed through the method of advanced drilling and exploration. , get the drilling histogram of each foundation pile hole, the drilling histogram includes drilling coordinates, drilling depth, hole elevation, description of the soil quality of the stratum, depth of layer bottom, thickness of layer, elevation of layer bottom, etc. content. Carry out the construction of prestressed pipe pile by the present invention then, specifically comprise the following steps:

[0034] a. Carry out the construction work of the pipe pile, and press the pipe pile into the soil layer;

[0035] b. According to the borehole histogram, input the layer thickness and mechanical properties of various soil layers around the pipe pile into BIM, and establish a 3D model of the pipe pile. The mechanical pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com