Test method for fatigue crack growth rate of steel box girder

A technology of fatigue crack growth and rate testing, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems that the physical structure is far apart, cannot be dynamically collected in real time, and is difficult to obtain, so as to save the stoppage test Time to measure crack length, avoid crack tip plastic passivation, real and reliable effect of growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] The test method for fatigue crack growth rate of steel box girder includes the following steps:

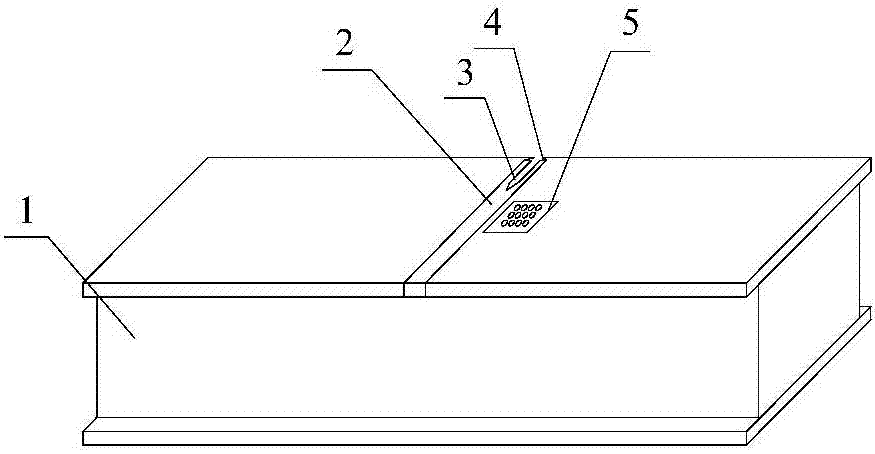

[0037] A. Preparation of steel box girder structural member samples

[0038] a1) According to the actual size of the steel box girder to be tested, the steel box girder sample is reduced in proportion according to the composition of the physical structure of the steel box girder to be tested and the welding process. The actual size and structure of the box girder are consistent, and the constraint state around it after the crack is formed is consistent with the actual steel box girder under test;

[0039] a2) Determine the dangerous section prone to crack propagation on the steel box girder sample according to the stress characteristics of the measured steel box girder physical structure, and process the mechanical notch on the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com