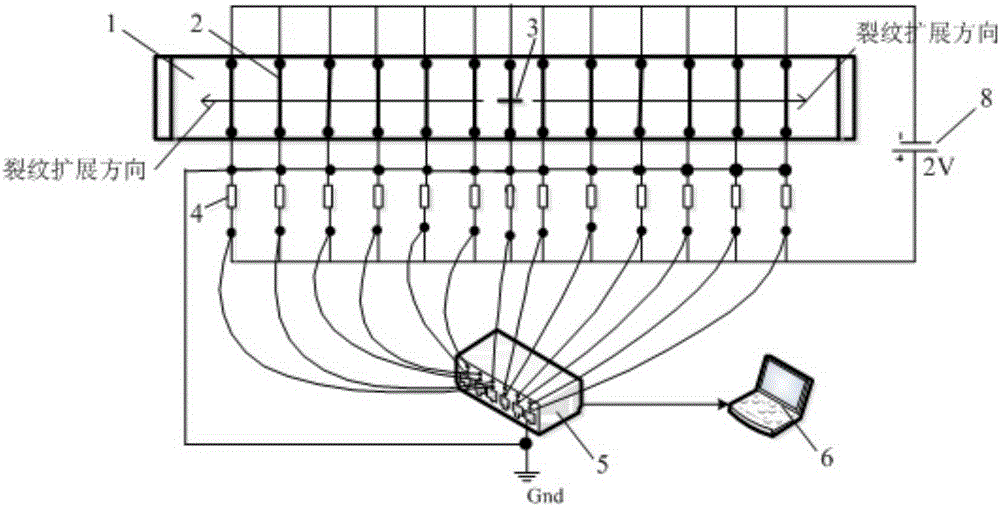

Pressurization device, tube wall crack propagation speed testing device, pressurization method and testing method

A pressurizing device and pipe wall technology, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, strength characteristics, etc., can solve damage to buildings and facilities, economic loss and environmental pollution, long pipeline Problems such as distance expansion, to achieve the effect of safe and reliable test method, safe method and meeting the test requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

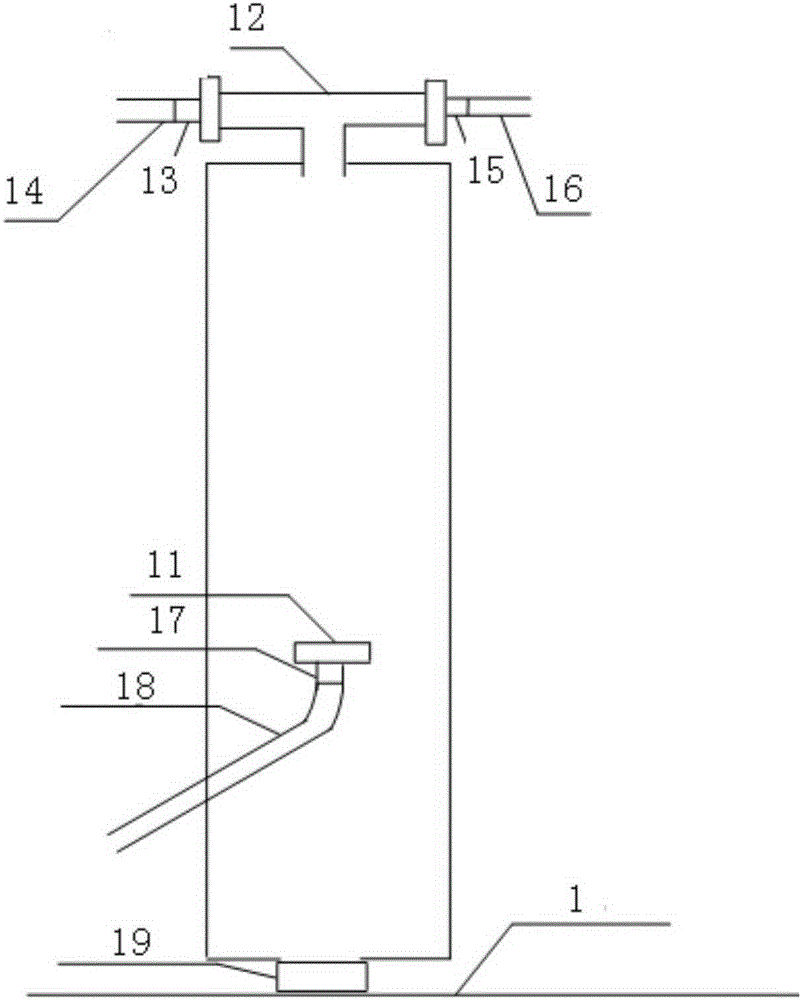

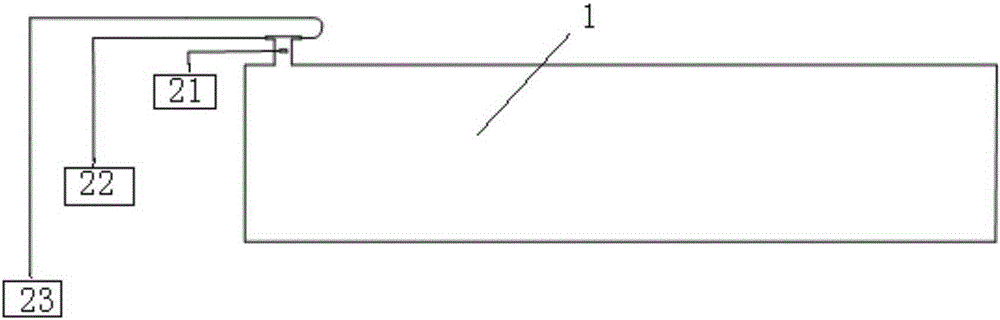

[0035] Such as figure 1 and figure 2 As shown, a pressurizing device of the present invention includes a high-pressure gas delivery pipe for delivering high-pressure gas to the metal pipe 1, a Class A air compression device 21, a Class B air compression device 22, and a Class C air compression device 23. The high-pressure gas delivery pipe communicates with the metal pipe 1 through a primary valve 19, the Class A air compression device 21 is installed on the high-pressure gas delivery pipe, and the end of the high-pressure gas delivery pipe is provided with a three-way converter 12. They are respectively connected with the Class B air compression device 22 and the Class C air compression device 23 . Wherein, the Class A air compression device 21 includes a first two-stage valve 11, a first conversion joint 17 and a first air delivery pipe 18, and the first air delivery pipe 18 is connected to the first two-stage valve 11 through the first conversion joint 17, The first two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com