Patents

Literature

51 results about "C++ classes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A class in C++ is a user-defined type or data structure declared with keyword class that has data and functions (also called member variables and member functions) as its members whose access is governed by the three access specifiers private, protected or public. By default access to members of a C++ class is private. The private members are not accessible outside the class; they can be accessed only through methods of the class. The public members form an interface to the class and are accessible outside the class.

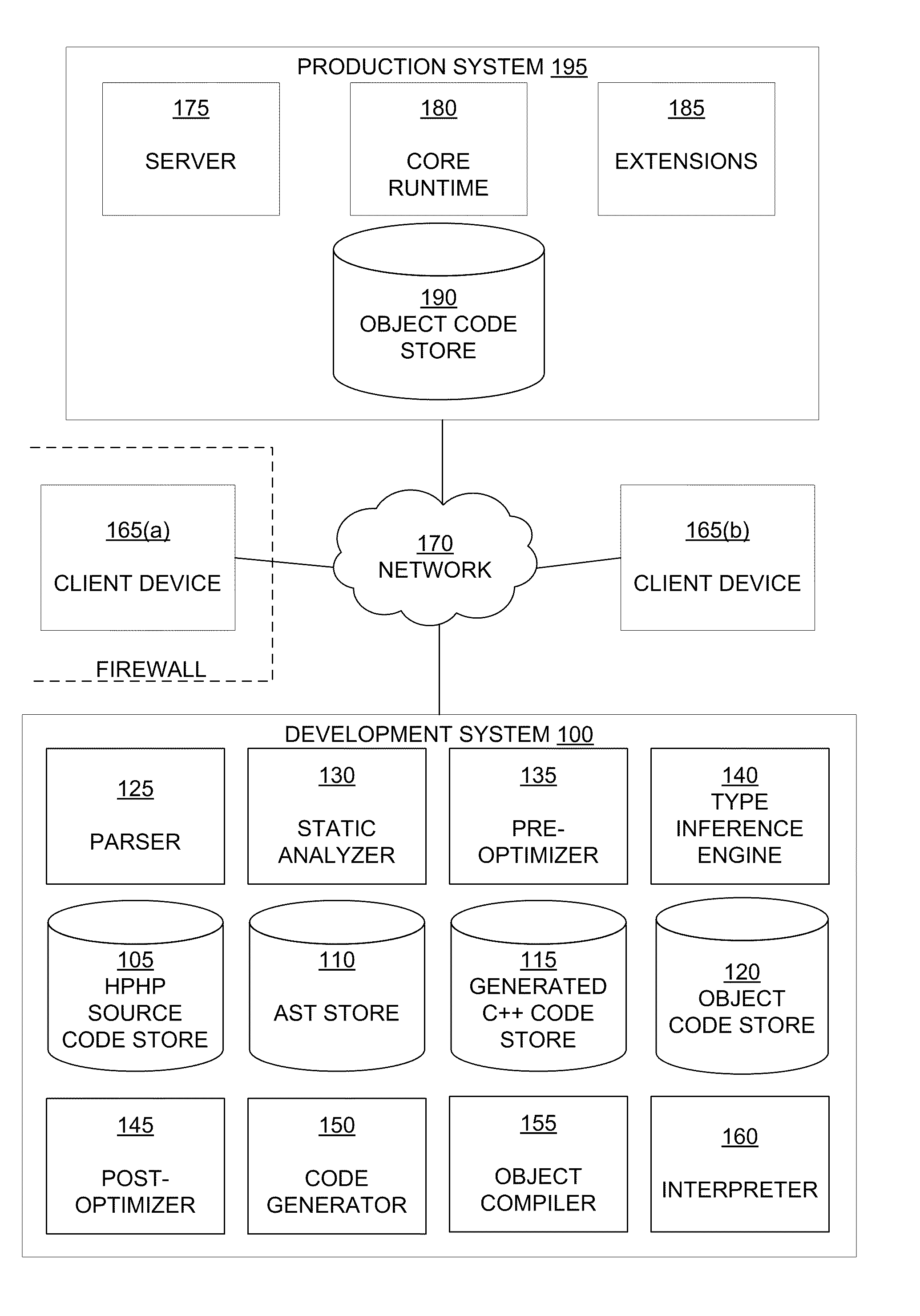

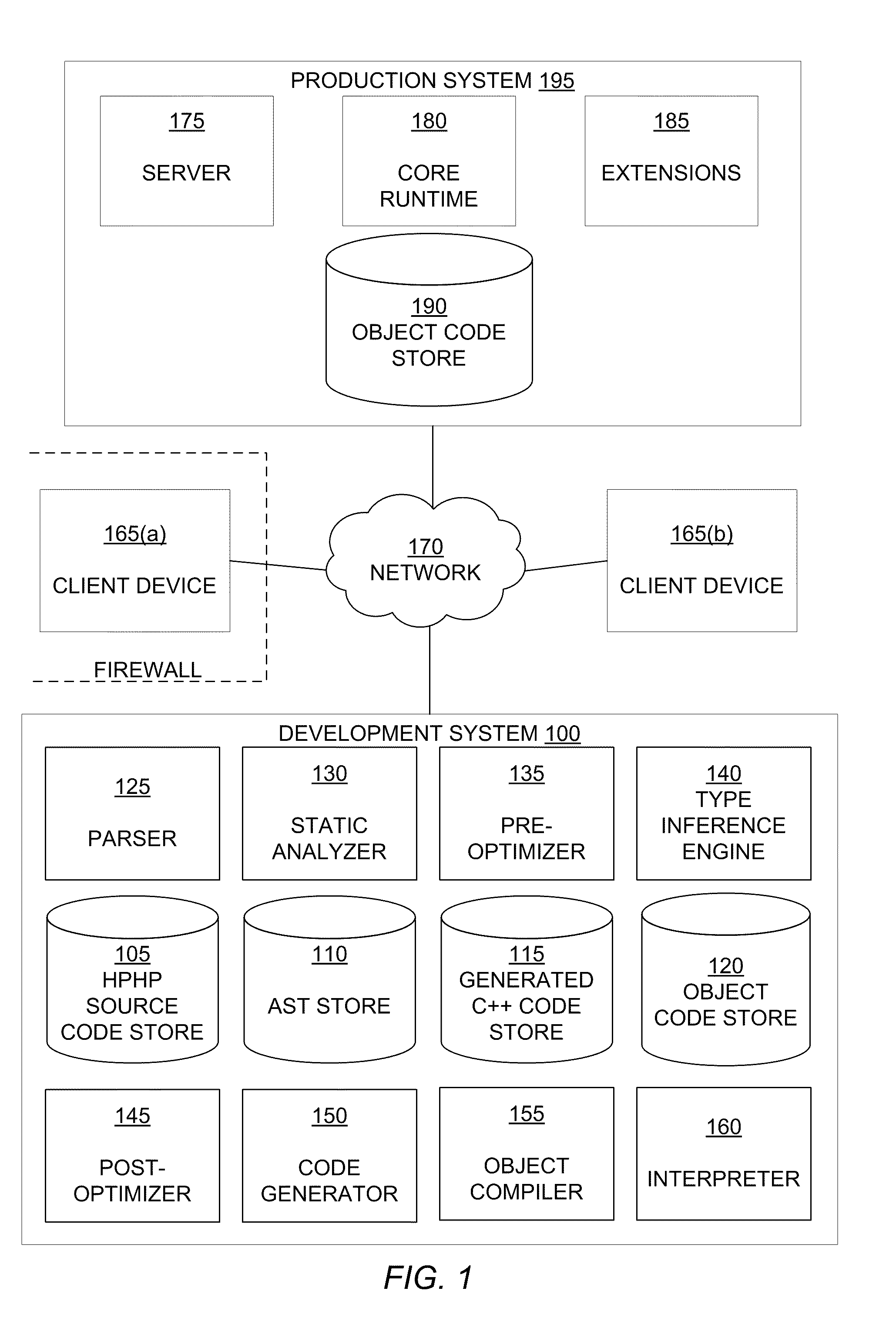

High performance php

ActiveUS20110179347A1Programming languages/paradigmsNatural language data processingObject codeDocument preparation

Markup language documents including server side scripting code using PHP syntax are executed efficiently in response to requests received by a server. The processing of the markup language document results in generation of a transformed markup language document that is returned in response to the request. The server side script code is input to a compiler that generates C++ code (or code in any object-based language based on C language) implementing the functionality of the server side script code. The C++ code is compiled to generated object code which is executed in order to process the markup language document. The generated C++ code includes functionality supported by PHP language including redeclaration of functions, dynamic variables, global variables, and the like. The generated C++ code invokes memory allocation code that allocates and deallocates objects obtained by instantiating the generated C++ classes.

Owner:META PLATFORMS INC

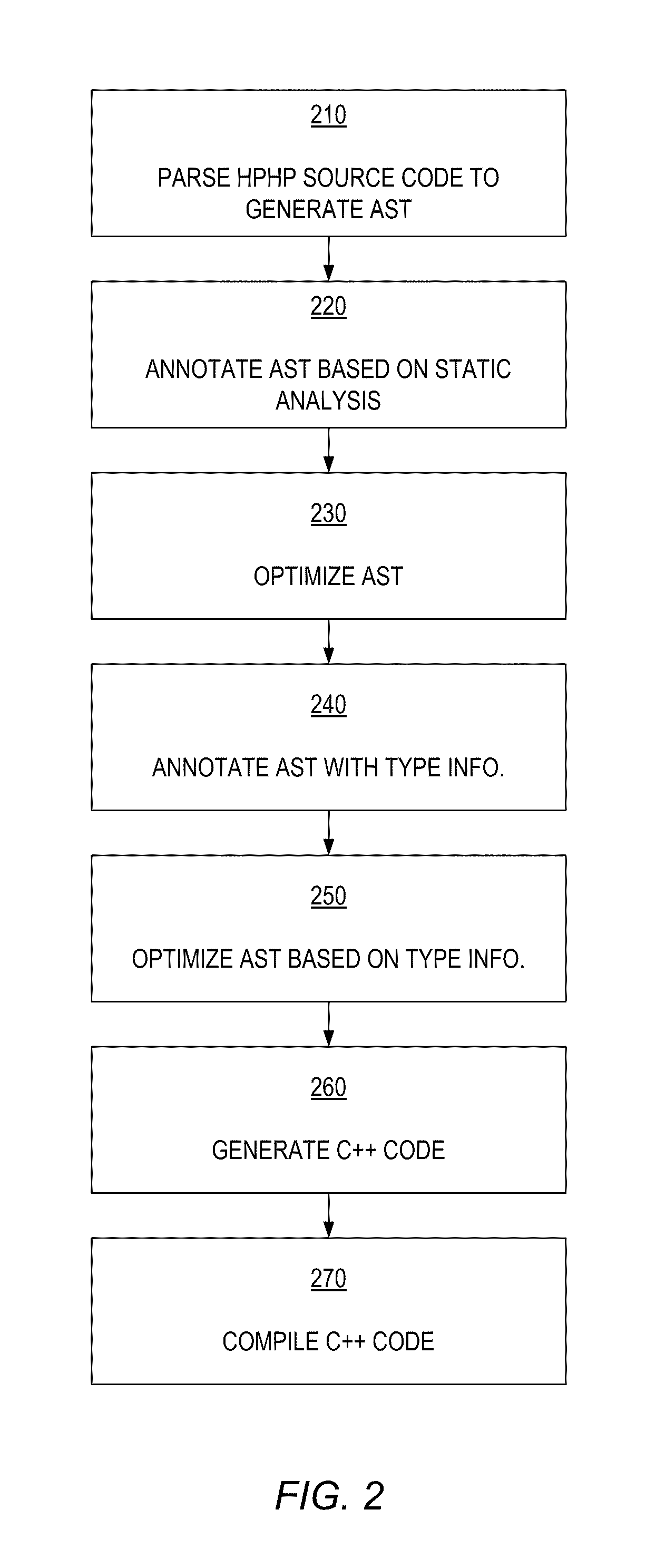

User mode network protocol stack system and method for processing message

ActiveCN101867558AImprove securityImprove security management and control capabilitiesTransmissionComputer hardwareNetworking protocol

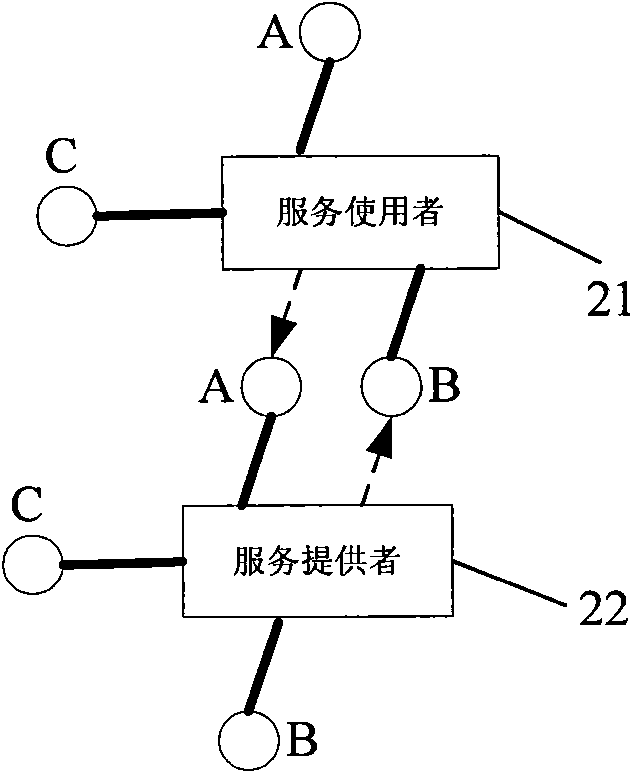

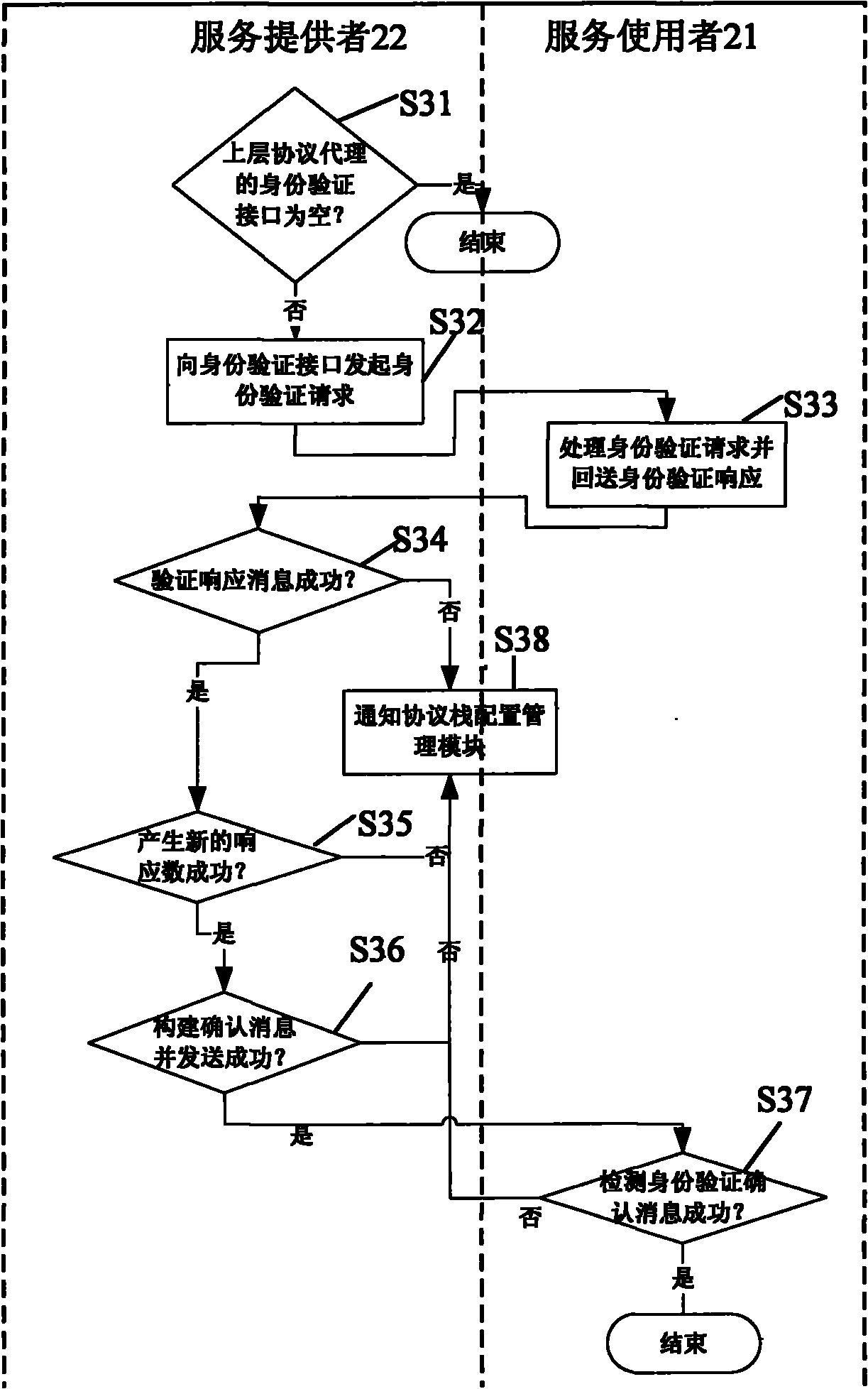

The invention relates to a user mode network protocol stack system, which comprises a protocol stack configuration management module, an array receiving module, an array sending module and a plurality of proxy protocol modules. The protocol stack configuration management module is used for cutting proxy protocols in a protocol stack and configuring the filter rule of each proxy protocol; the array receiving module is used for managing a cache region which receives a message; the array sending module is used for managing a cache region which sends the message; the plurality of proxy protocol modules are positioned on a plurality of layers; each proxy protocol module comprises an A-class interface, a B-class interface and a C-class interface; the A-class interface is used for receiving the message sent by the upper layer of proxy protocol module; the B-class interface is used for the lower layer of proxy protocol module to submit the message; and the C-class interface is used for the protocol stack configuration management module to configure the proxy protocol module. The invention realizes a user mode network protocol stack through the protocol stack configuration management module.

Owner:SHENZHEN Y& D ELECTRONICS CO LTD

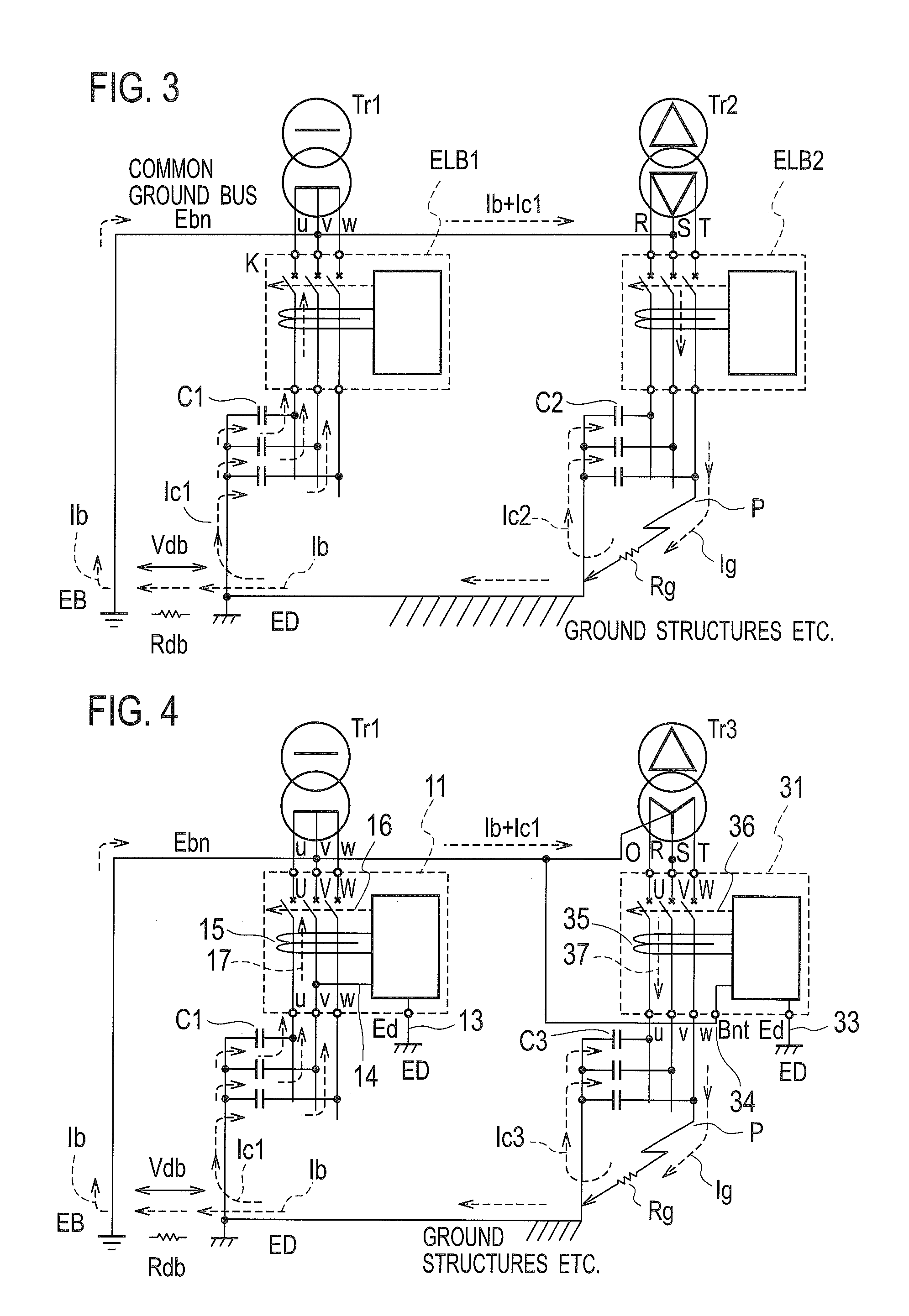

Earth leakage detector with suffered current-blocking function

ActiveUS20130063842A1Reduce stepsReduce riskSwitch operated by earth fault currentsShort-circuit testingElectricityElectrical devices

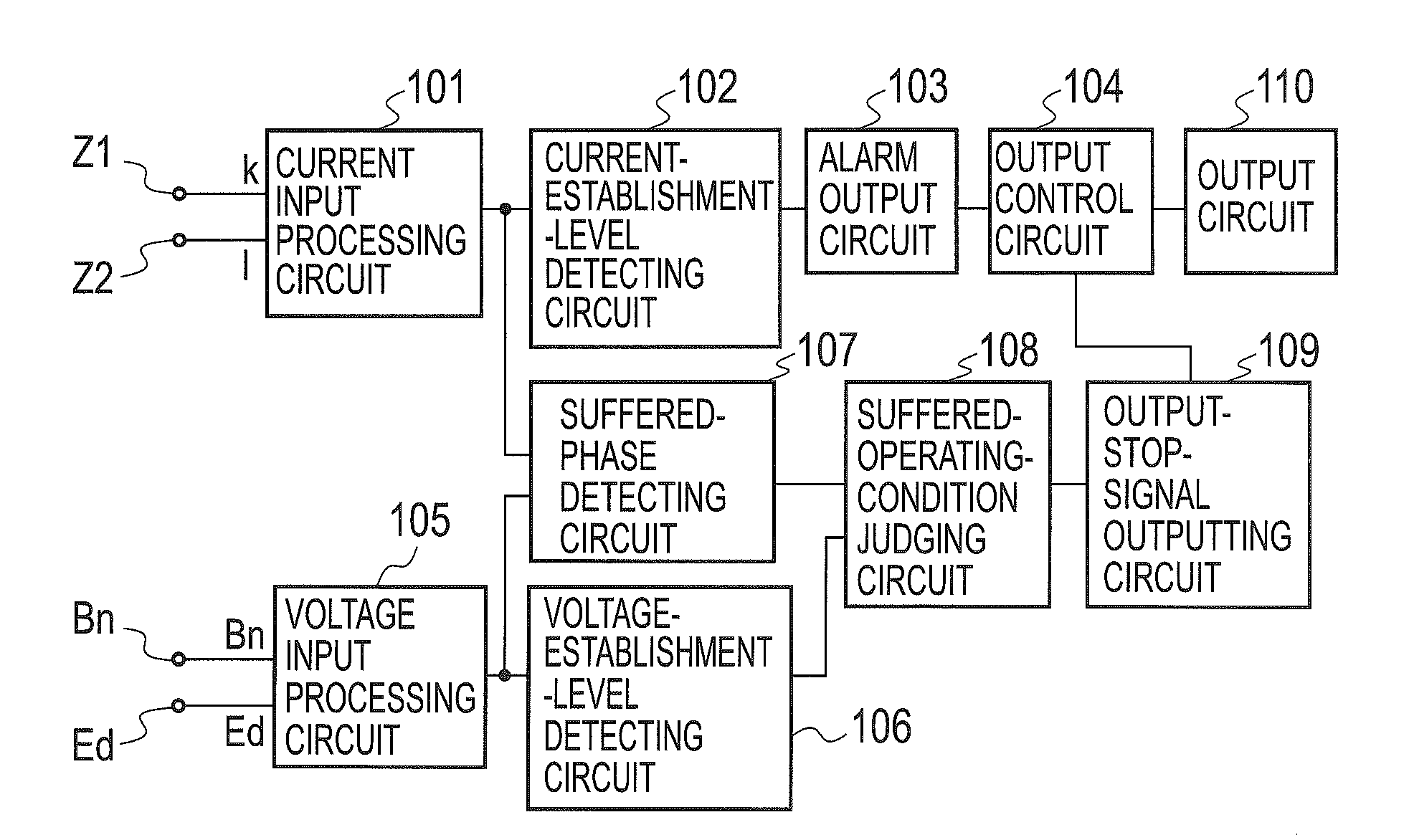

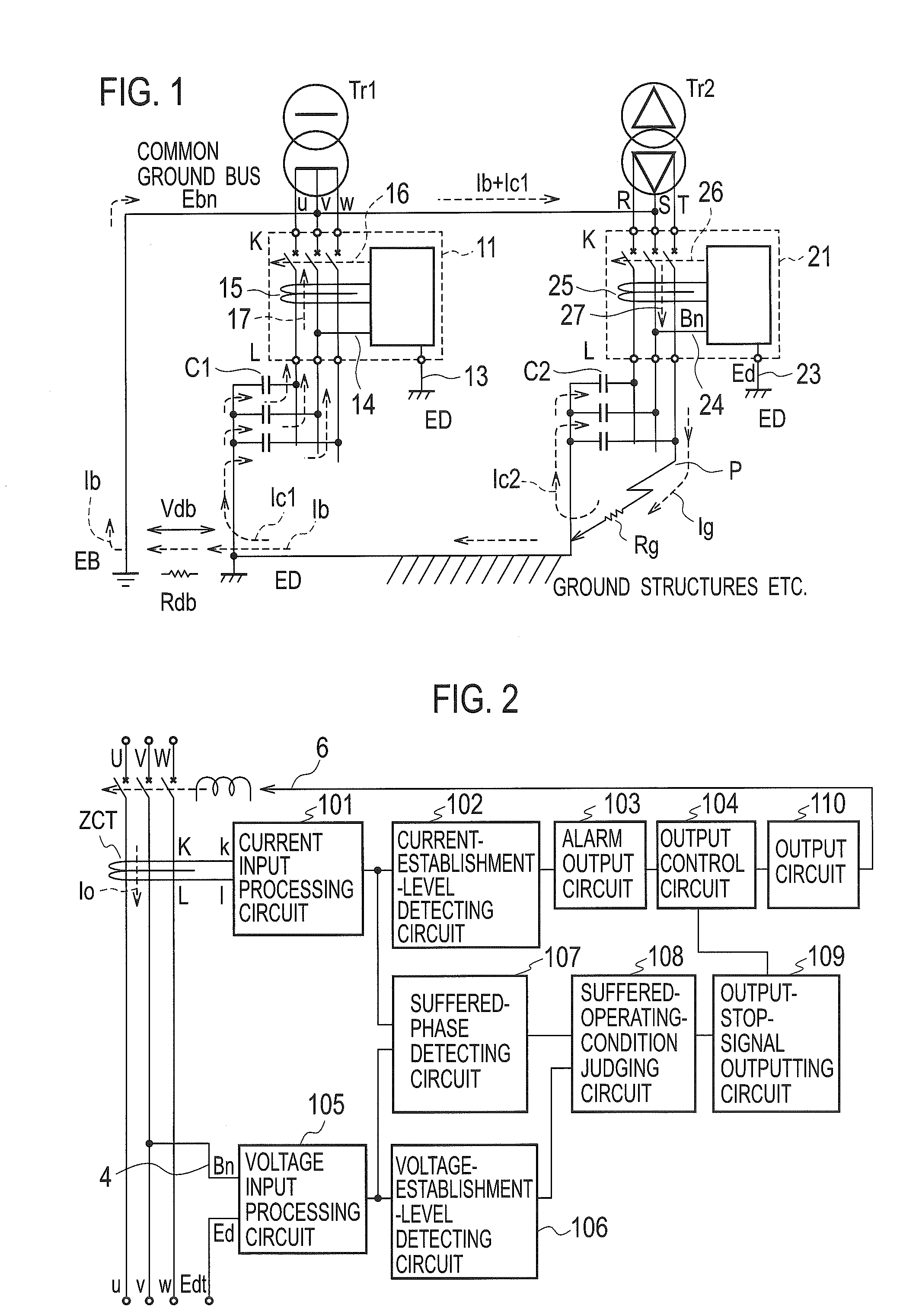

A leakage detector is provided with the addition of an output control circuit that monitors a circuit wire-to-ground voltage, which is at the root of a suffered operation and produced between a transformer B-class grounding phase of a monitored circuit and a D or C-class grounding electrode or a ground structure etc. of an electrical equipment connected to the grounding electrode, execute a phase judgment of a leakage current detected by a zero-phase current transformer on the basis of the monitored voltage, and stop an output operation of the leakage detector when the leakage current is a suffered current flowing from a load side L of the detecting zero-phase current transformer toward the power side K, i.e. the transformer and when the circuit wire-to-ground voltage exceeds an appropriately-established dynamic sensitivity voltage value.

Owner:LIFETECHNOS

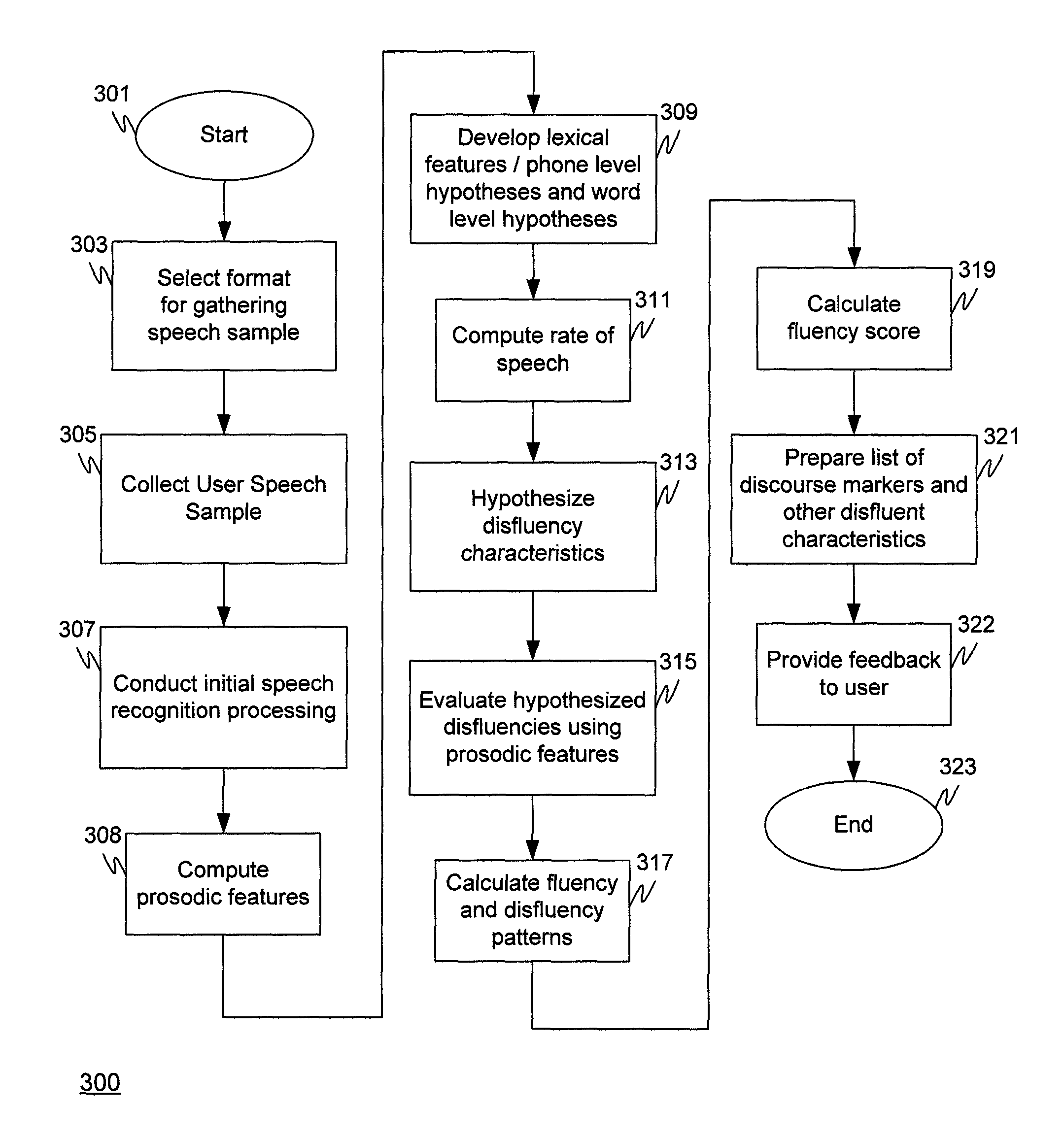

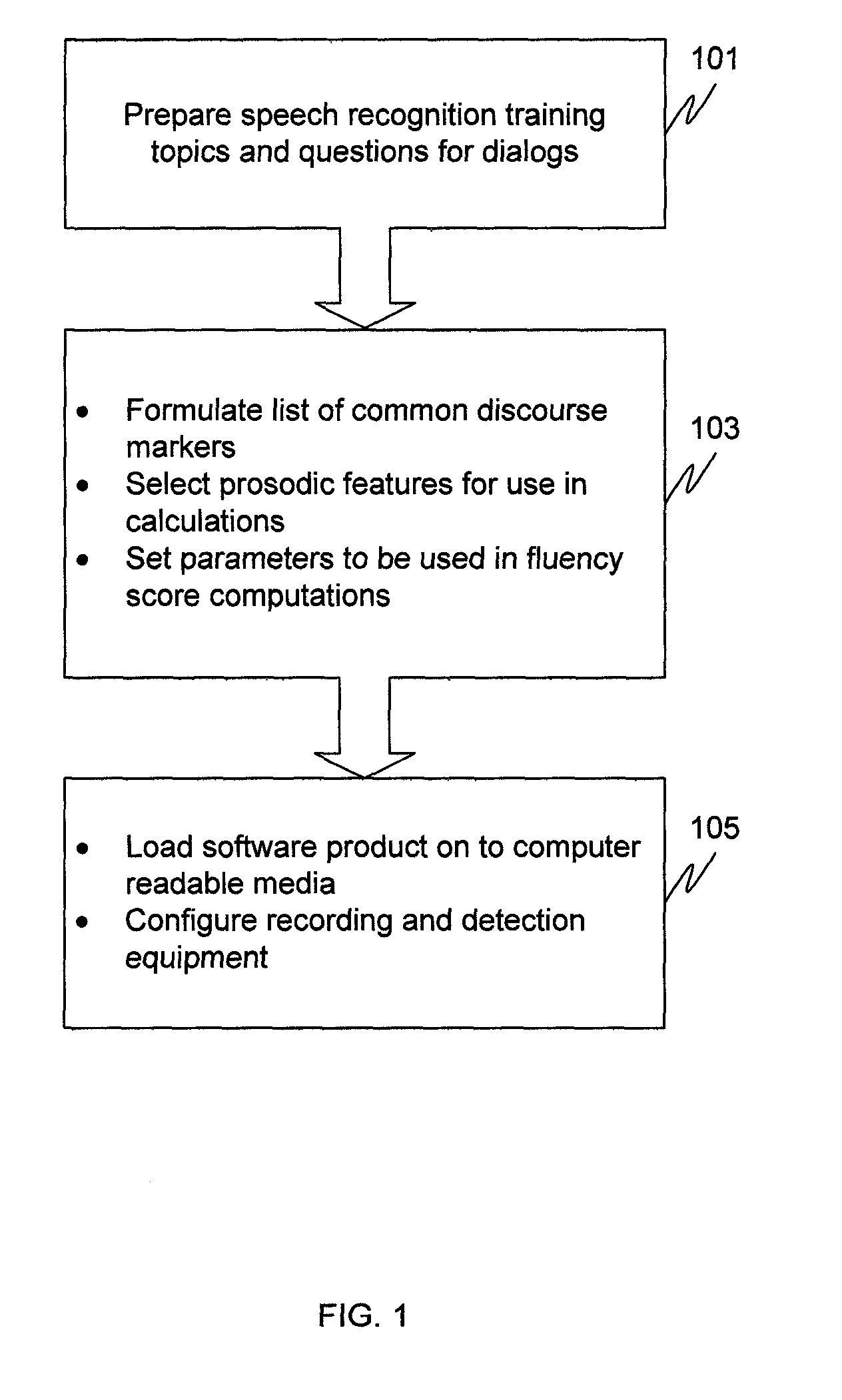

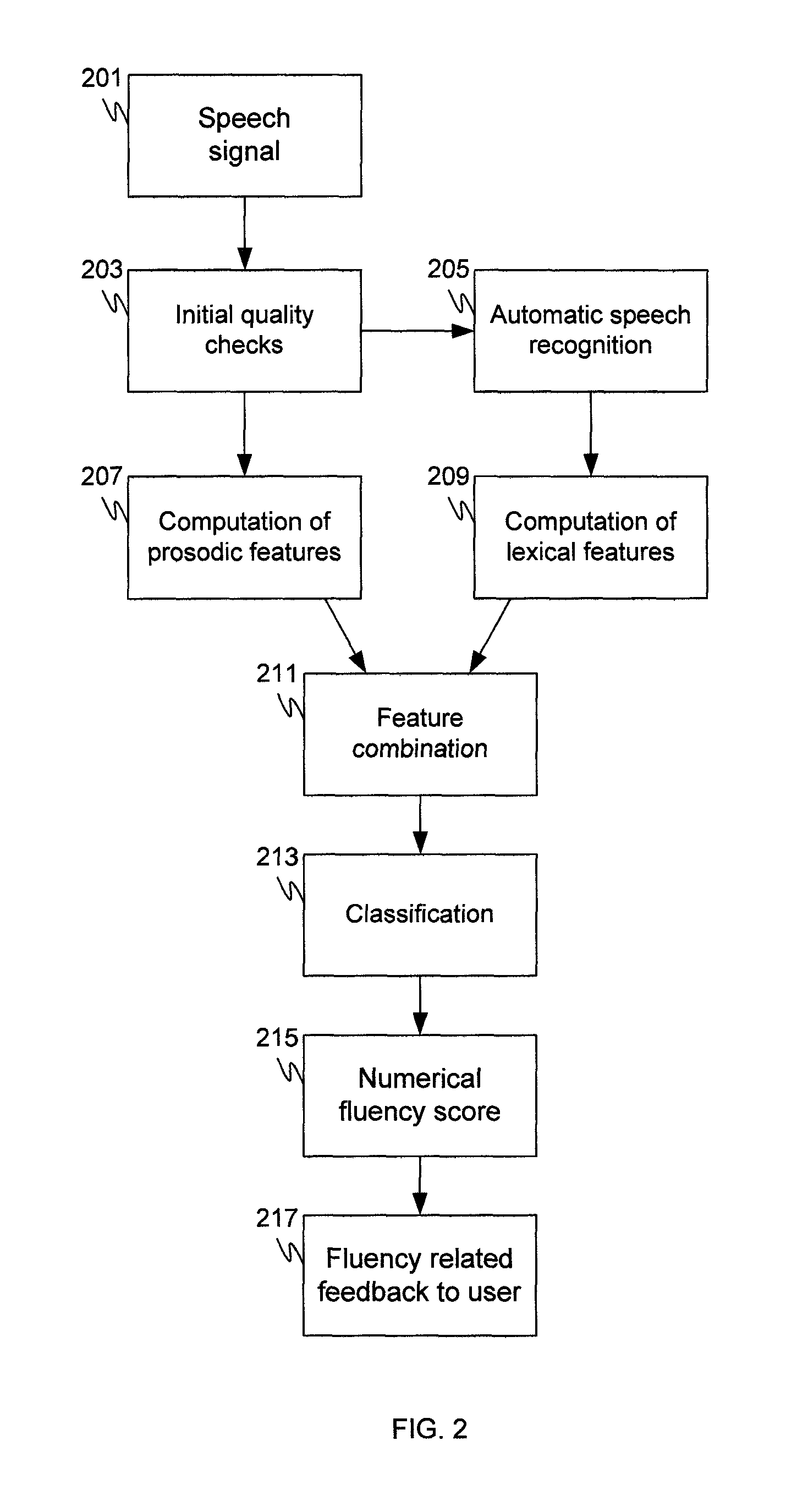

Automatic evaluation of spoken fluency

A procedure to automatically evaluate the spoken fluency of a speaker by prompting the speaker to talk on a given topic, recording the speaker's speech to get a recorded sample of speech, and then analyzing the patterns of disfluencies in the speech to compute a numerical score to quantify the spoken fluency skills of the speakers. The numerical fluency score accounts for various prosodic and lexical features, including formant-based filled-pause detection, closely-occurring exact and inexact repeat N-grams, normalized average distance between consecutive occurrences of N-grams. The lexical features and prosodic features are combined to classify the speaker with a C-class classification and develop a rating for the speaker.

Owner:MICROSOFT TECH LICENSING LLC

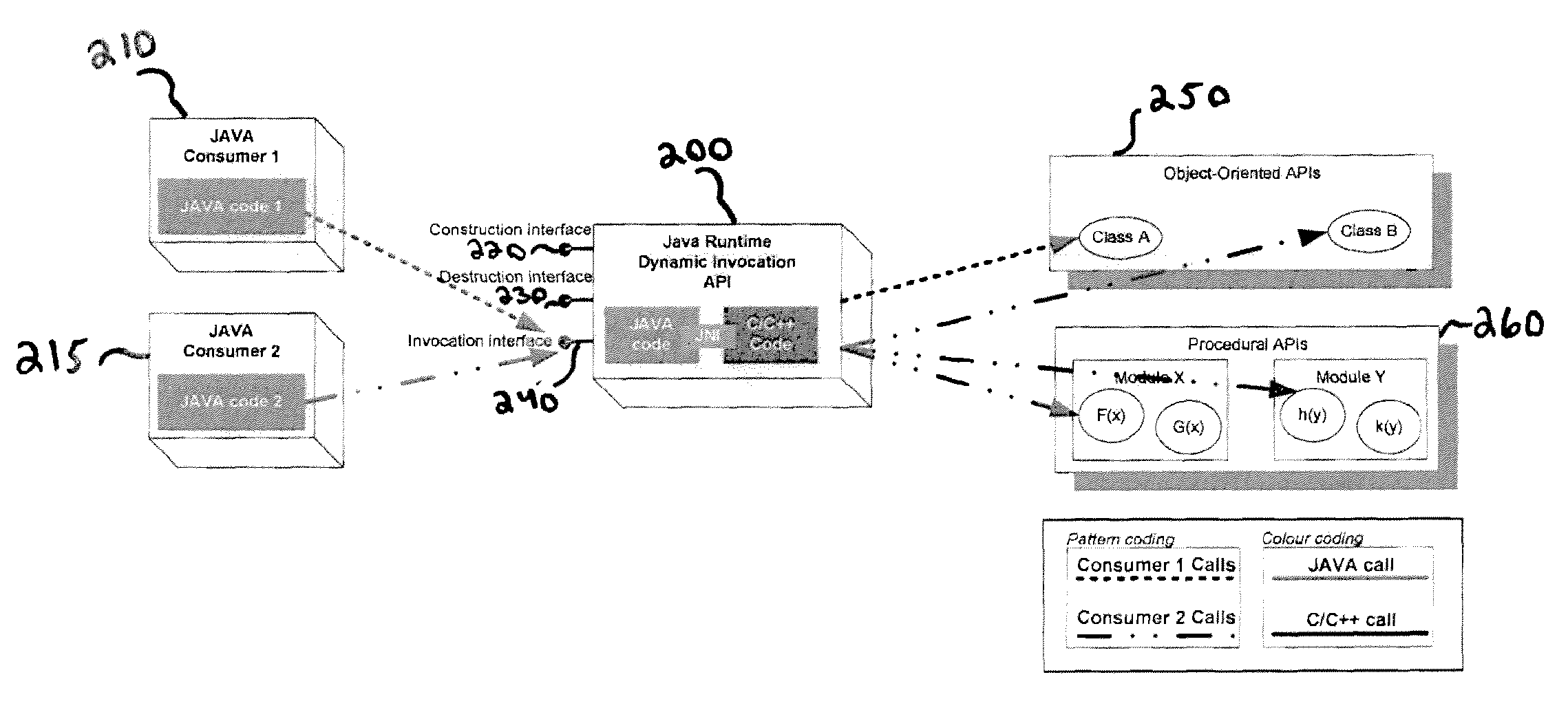

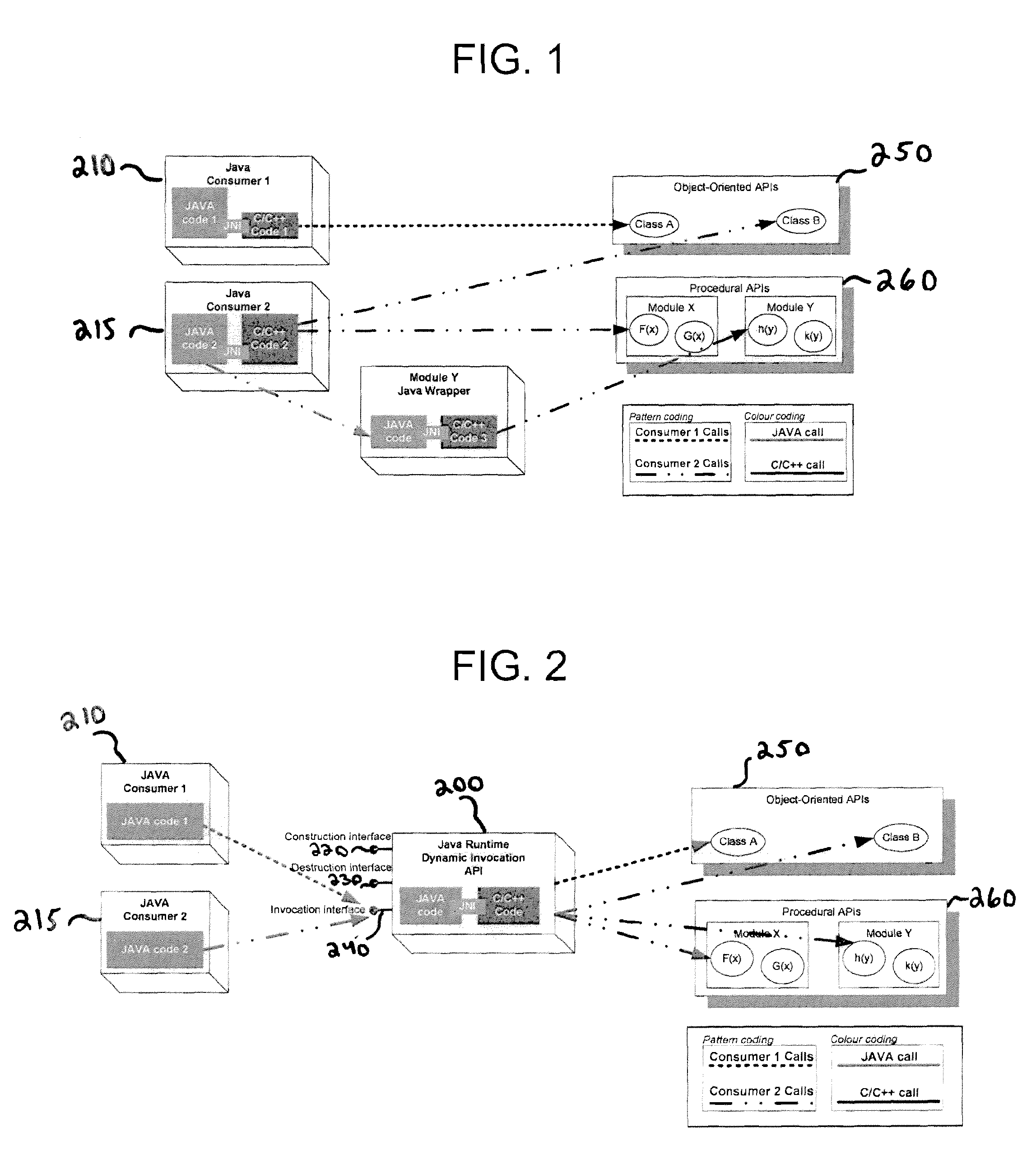

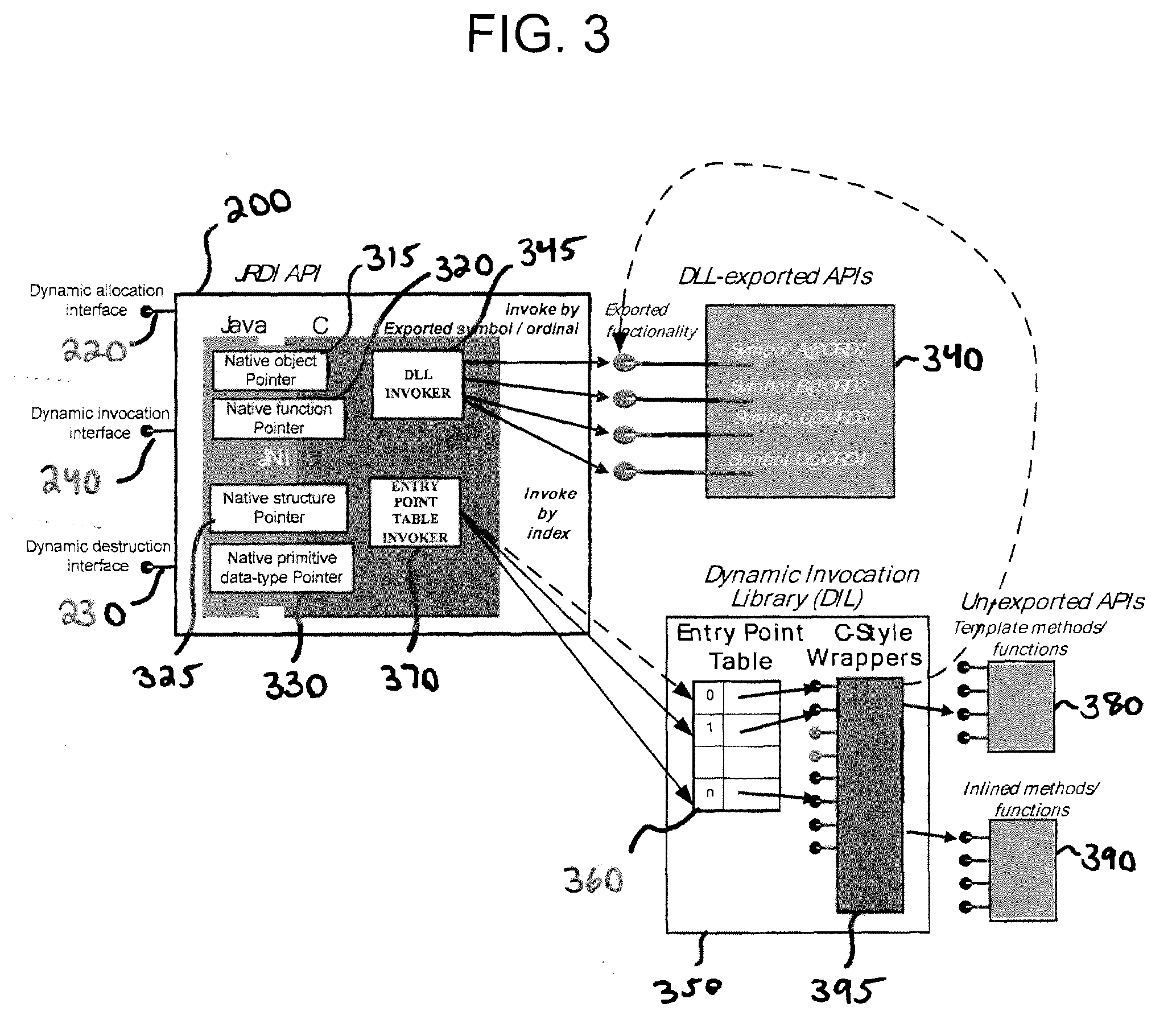

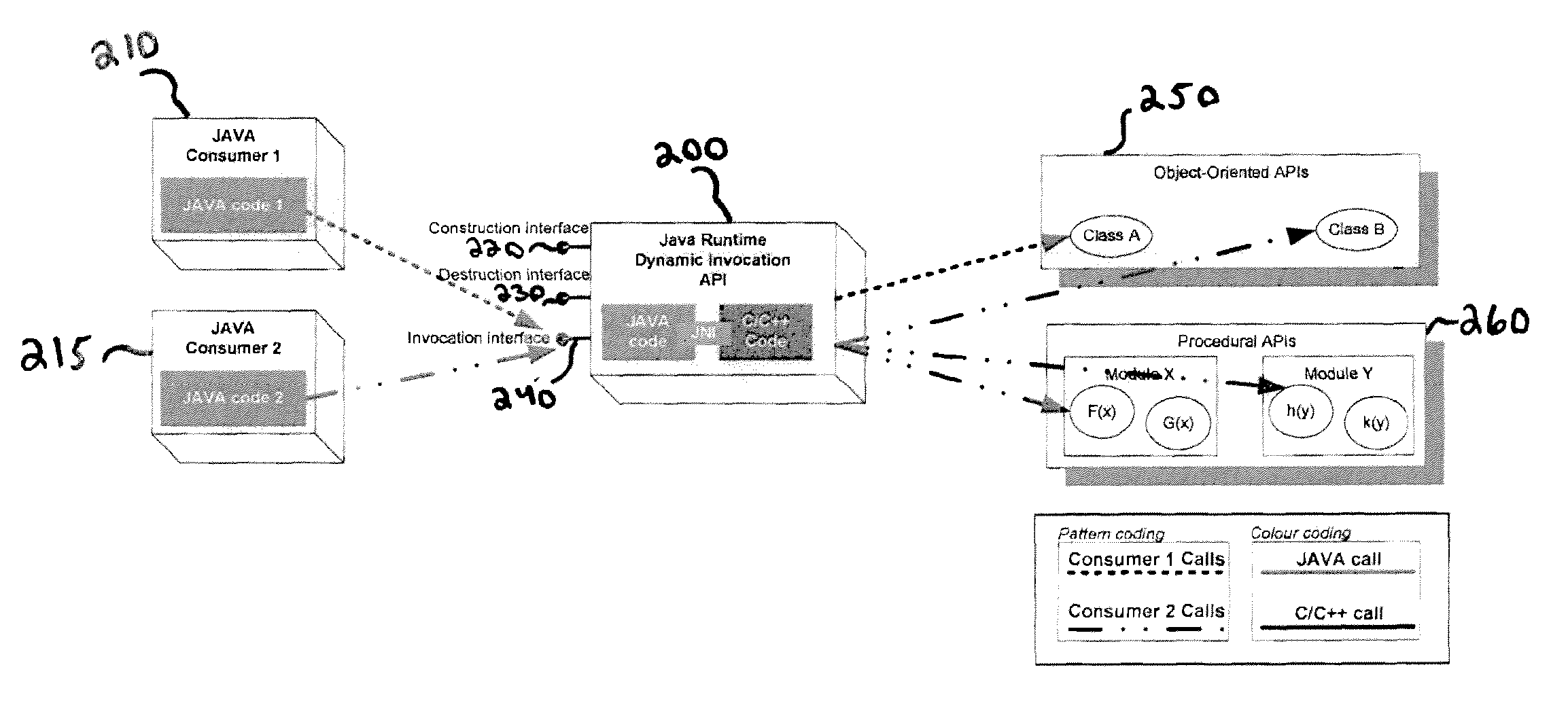

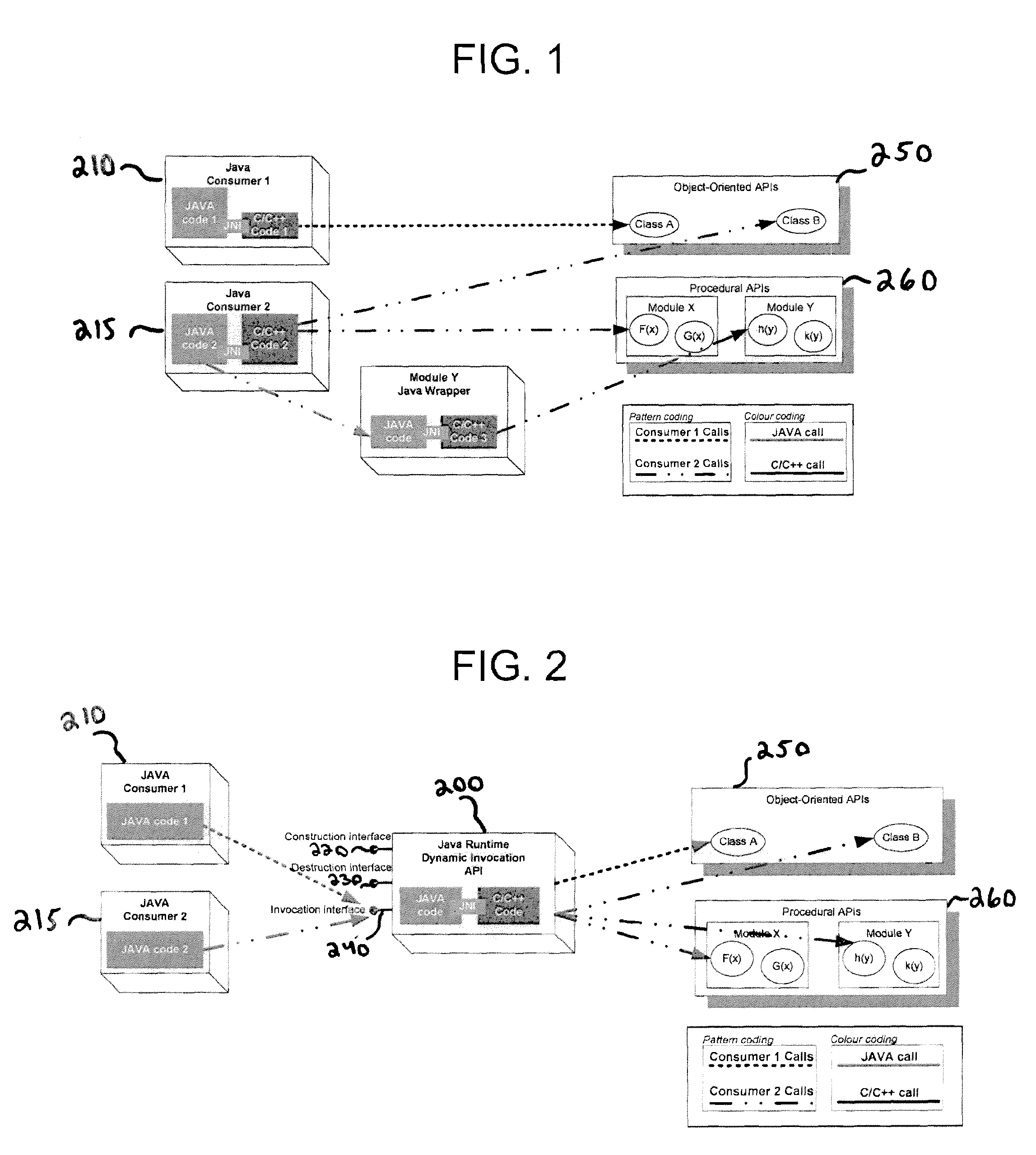

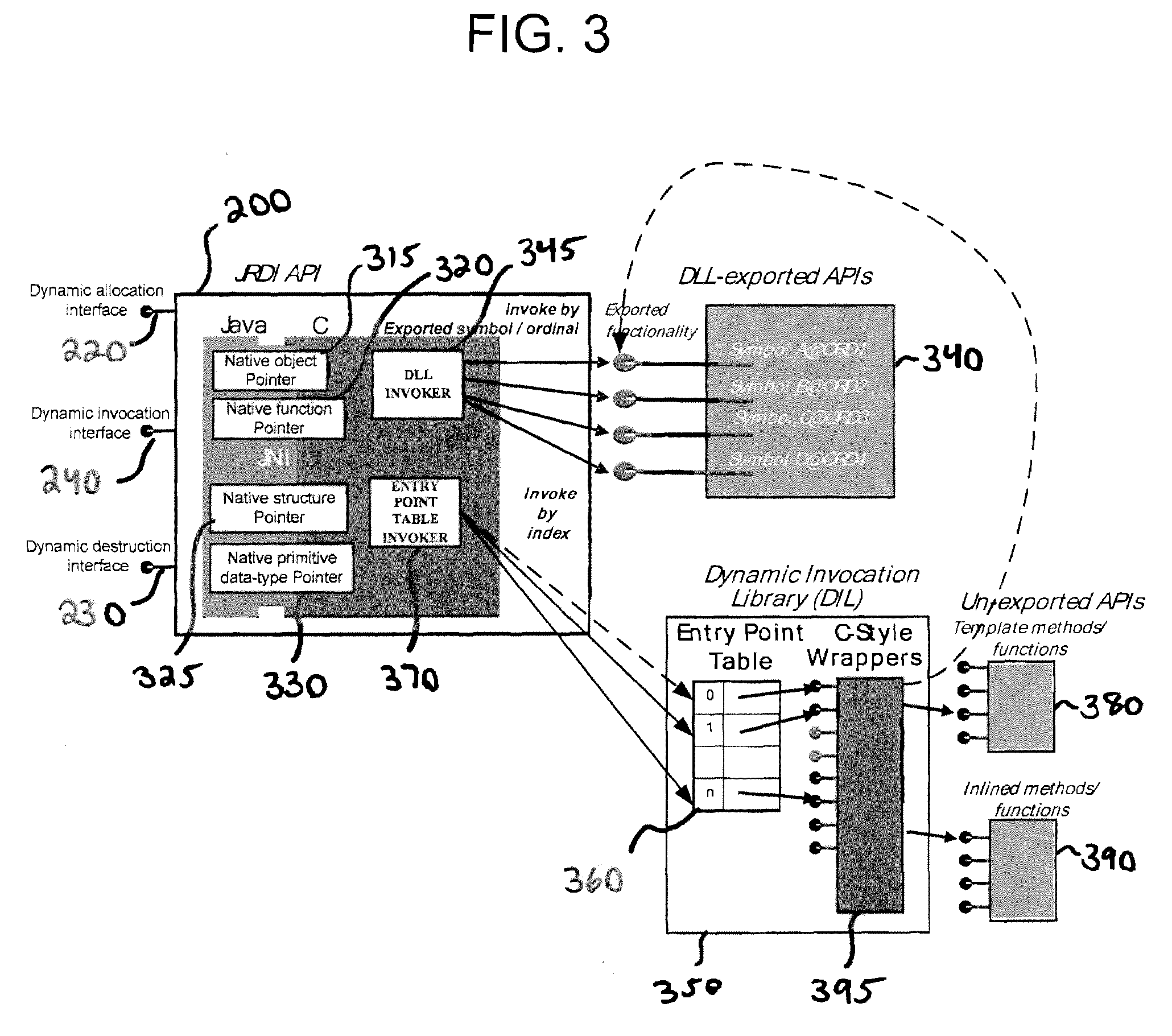

System and method for reducing the static footprint of mixed-language JAVA classes

InactiveUS20080163265A1Minimizing functionality-gapSmall footprintSpecific program execution arrangementsCode compilationProgramming languageJava classes

A system and a method for minimizing the functionality-gap between Java and native platforms while keeping the impact on each Java API static footprint as small as possible. A Java Runtime Dynamic Invocation API is used for low-level bridging between Java and C / C++, enabling the dynamic invocation of native C / C++ functions and C++ class / object methods from the Java side without adding any additional ad hoc implemented native code to the overall Java component implementation. Thereby, the need to write new native code when implementing a Java component that needs to invoke some native functionality is reduced.

Owner:CORE WIRELESS LICENSING R L

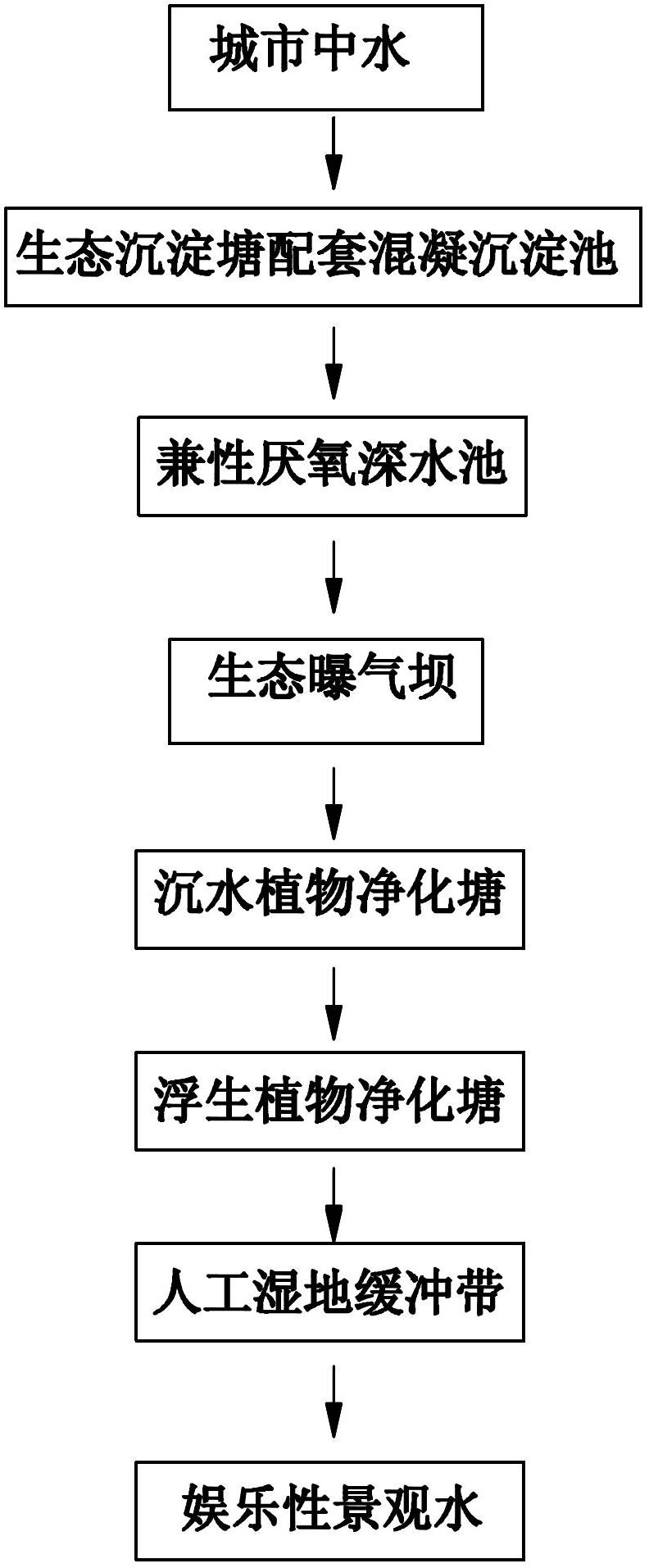

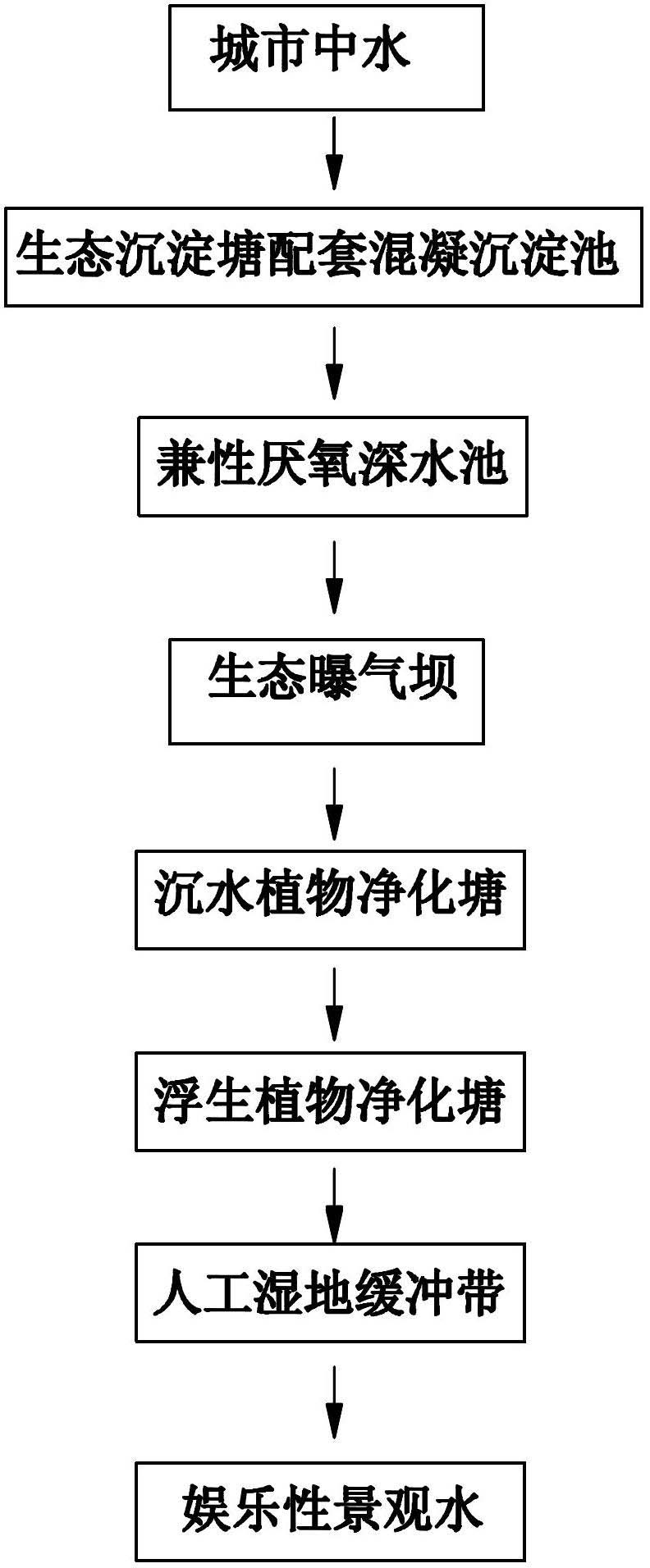

Treatment method for applying urban reclaimed water to landscape water

ActiveCN102674549AIncrease oxygen contentPromote rapid reproductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentBuffer stripConstructed wetland

The invention discloses a treatment method for applying urban reclaimed water to landscape water. The method mainly comprises the following steps of: building an ecological precipitation pond and a facultative anaerobic deep water pond, constructing an ecological aeration dam, and building a submerged plant purification pond, an aquatic plant purification pond, and an artificial wetland buffer zone; and allowing the urban reclaimed water to sequentially flow through the ecological precipitation pond, the facultative anaerobic deep water pond, the ecological aeration dam, the submerged plant purification pond, the aquatic plant purification pond and the artificial wetland buffer zone to obtain the treated water which is used as the landscape water. According to the urban reclaimed water which is treated by the method, the transparency is more than 0.5m, and dissolved oxygen is more than 2mg / L, and floater and fishy odor are avoided; and the landscape water completely meets the B and C-class water-quality standard of the landscape and entertainment water which is allowed to be contacted.

Owner:SHANDONG DONGSHENG GARDEN ENG CO LTD

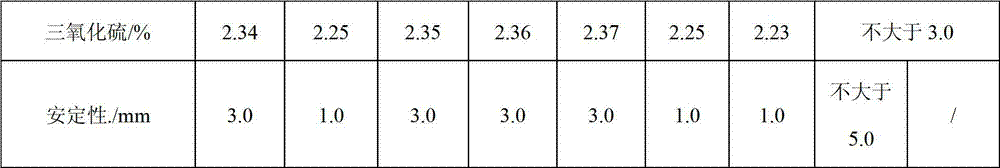

Modified coal ash used in cement and concrete and preparation method of modified coal ash

InactiveCN102951862AImprove activity indexReduce grinding energy consumptionSolid waste managementPolymer scienceCoal

The invention discloses modified coal ash used in cement and concrete and a preparation method of the modified coal ash. The modified coal ash comprises the following raw materials: 95-99wt% of F-class coal ash or C-class coal ash and 1-5wt% of sintering dry-process desulfurized fly ash. The modified coal ash has the characteristics of fineness being not more than 25.0 percent, water demand ratio being not more than 105 percent, ignition loss being not more than 8.0 percent, water content being not more than 1.0 percent, sulfur trioxide content being not more than 3.0 percent, free calcium oxide content being not more than 4.0 percent, qualified stability and strength activity index being not less than 78 percent. Compared with the common coal ash, the modified coal ash disclosed by the invention has the advantages that the 28-day activity index is greatly increased, the fineness requirement can be properly reduced, and the grinding energy consumption can be effectively reduced.

Owner:SHANGHAI BAOTIAN NOVEL BUILDING MATERIALS

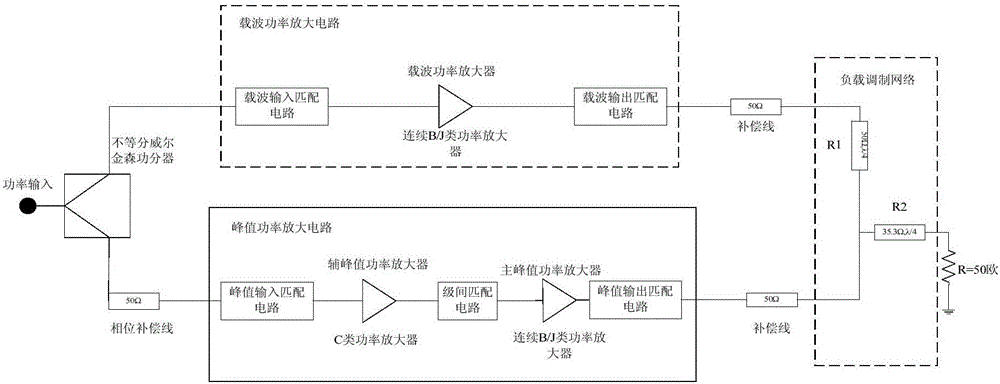

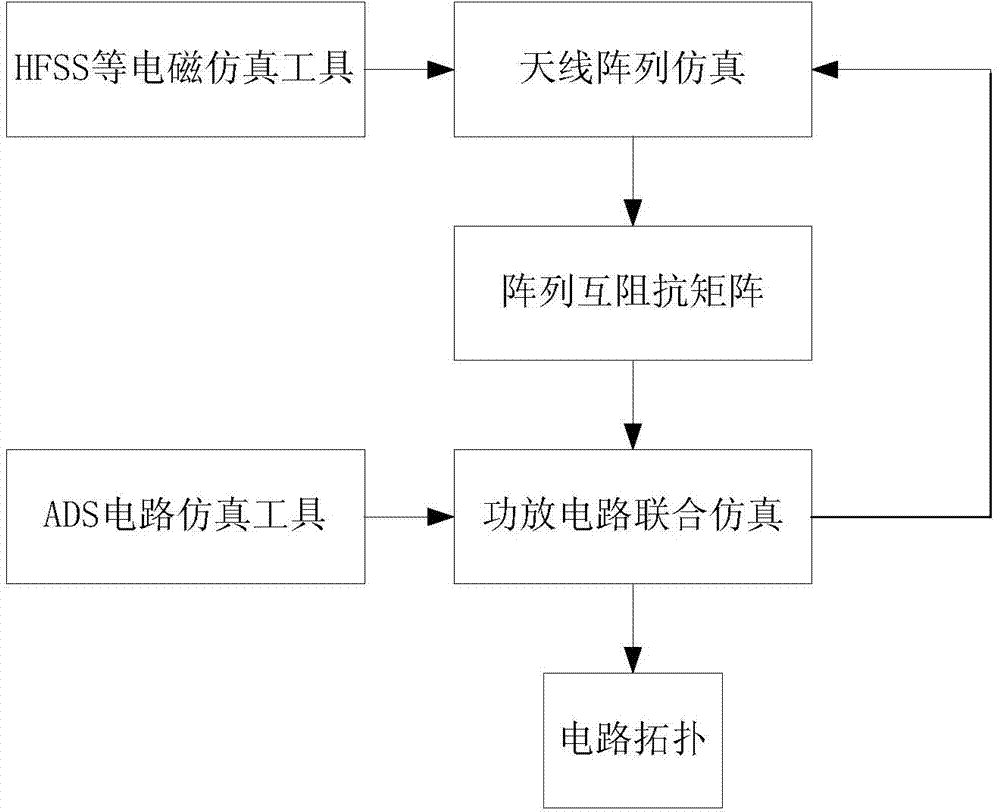

High-power and high-efficiency Doherty power amplifier

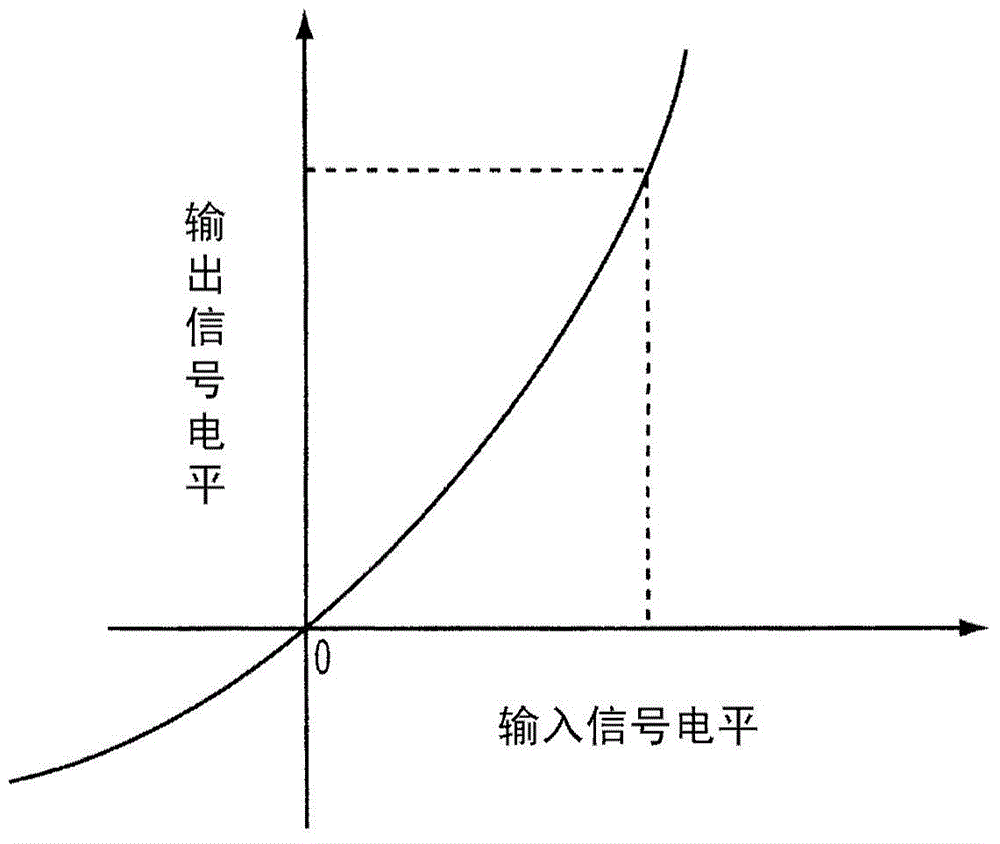

ActiveCN106301238AReduce areaIncrease saturated output powerAmplifier modifications to reduce non-linear distortionAmplifier modifications to raise efficiencyHarmonic controlCarrier signal

The invention provides a high-power and high-efficiency Doherty power amplifier. The high-power and high-efficiency Doherty power amplifier comprises an unequal Wilkinson power divider, a carrier power amplification circuit, a peak power amplifier circuit and a load modulation network, wherein the carrier power amplification circuit adopts a continuous B / J class power amplifier, the peak power amplifier circuit adopts a two-level power amplifier cascade structure, an auxiliary peak power amplifier circuit adopts a C class power amplifier, and a main peak power amplifier circuit adopts a B / J class power amplifier. Compared with the prior art, the high-power and high-efficiency Doherty power amplifier adopts a new Doherty structure, and accordingly, the saturated output power can be greatly improved while the efficiency is guaranteed; an auxiliary peak power amplifier adopts an ordinary C class, a main peak power amplifier and a carrier power amplifier adopt an continuous B / J class, secondary short circuit and quartic short circuit as well as tertiary and quintic open circuit can be well controlled by means of a harmonic control network, a current waveform output by power amplifiers approximates a half-sine wave, a voltage waveform approximates a square wave, and the backspacing efficiency and the saturated output power of Doherty are greatly improved.

Owner:HANGZHOU DIANZI UNIV

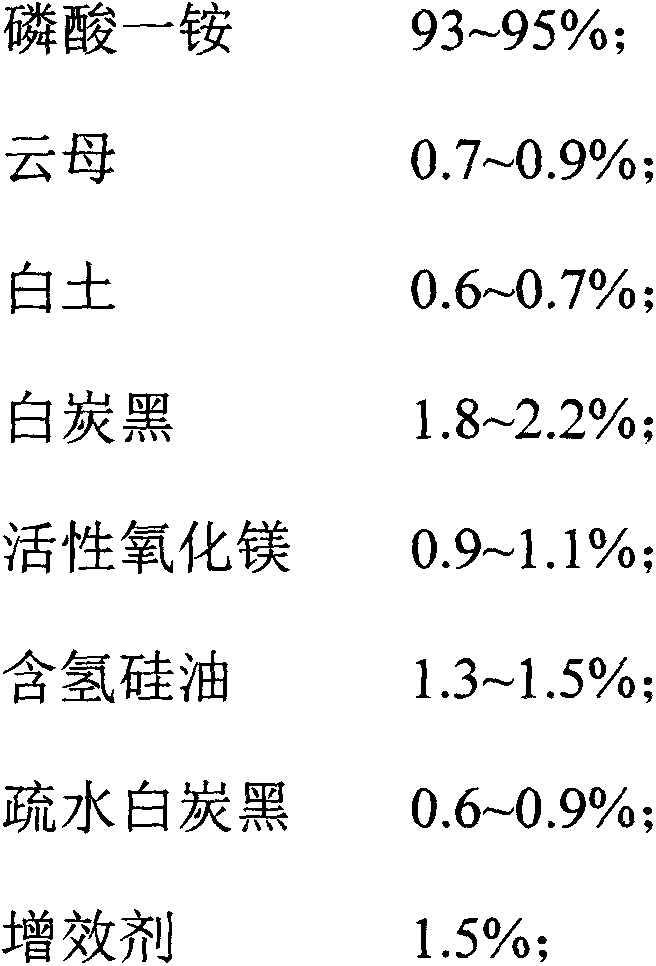

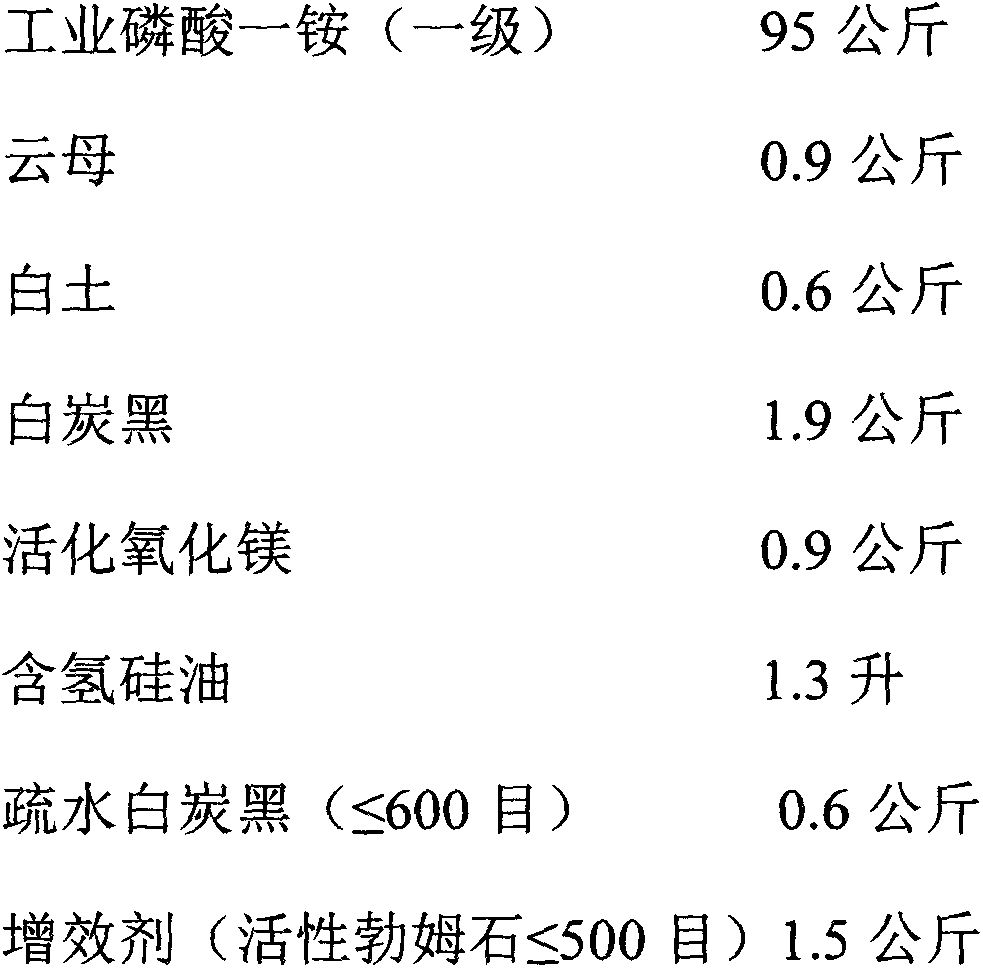

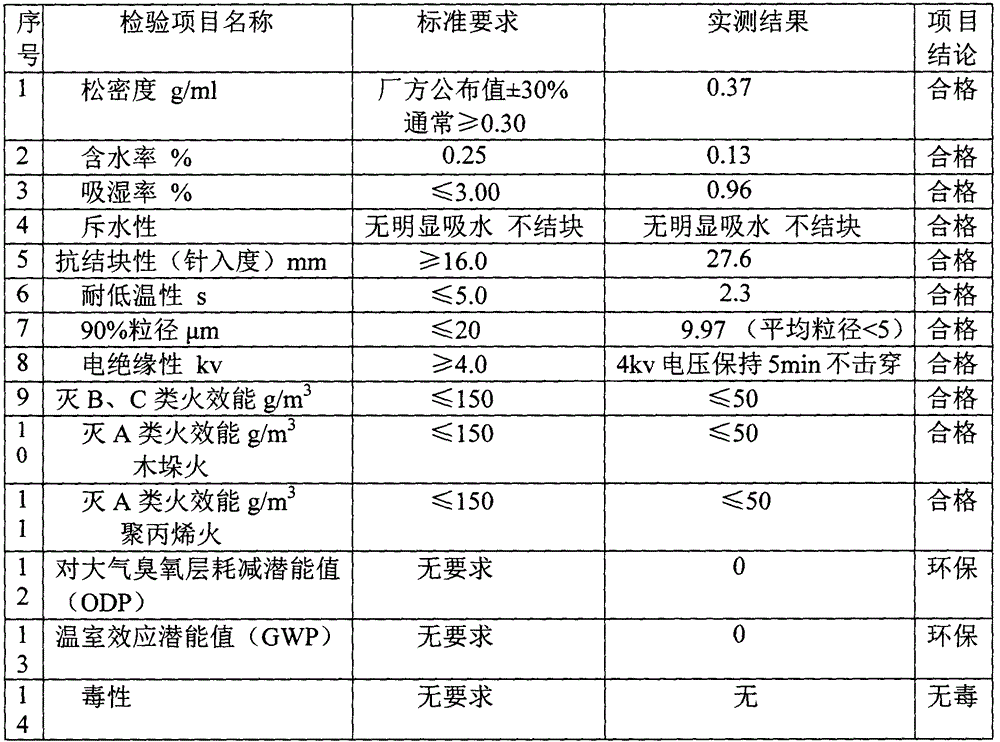

Ammonium phosphate high-effect superfine dry powder extinguishing agent and production method thereof

InactiveCN105999606AImprove flame retardant performanceFunction increaseFire extinguisherEnvironmental resistanceUltra fine

The invention adopts the ammonium phosphate high-efficiency superfine dry powder fire extinguishing agent produced by sub-nanometer ultrafine grinding, synergistic effect and surface modification technology, which realizes the fire extinguishing efficiency of more than 10 times that of ordinary dry powder fire extinguishing agent, and can be widely used in extinguishing A and B , Class C, and E fires, with excellent submerged fire extinguishing efficiency and smoke suppression function, and long storage period, environmentally friendly and non-toxic, many parameters, especially fire extinguishing efficiency, are far superior to the requirements of the GA578‑2005 "Ultrafine Dry Powder Fire Extinguishing Agent" standard. It can be filled with various fire extinguishing devices and pipe network fire extinguishing systems commonly used at present, and can even be used as a cold aerosol. The invention has simple production process, less equipment investment and low production cost, and is suitable for large-scale production.

Owner:杨根喜

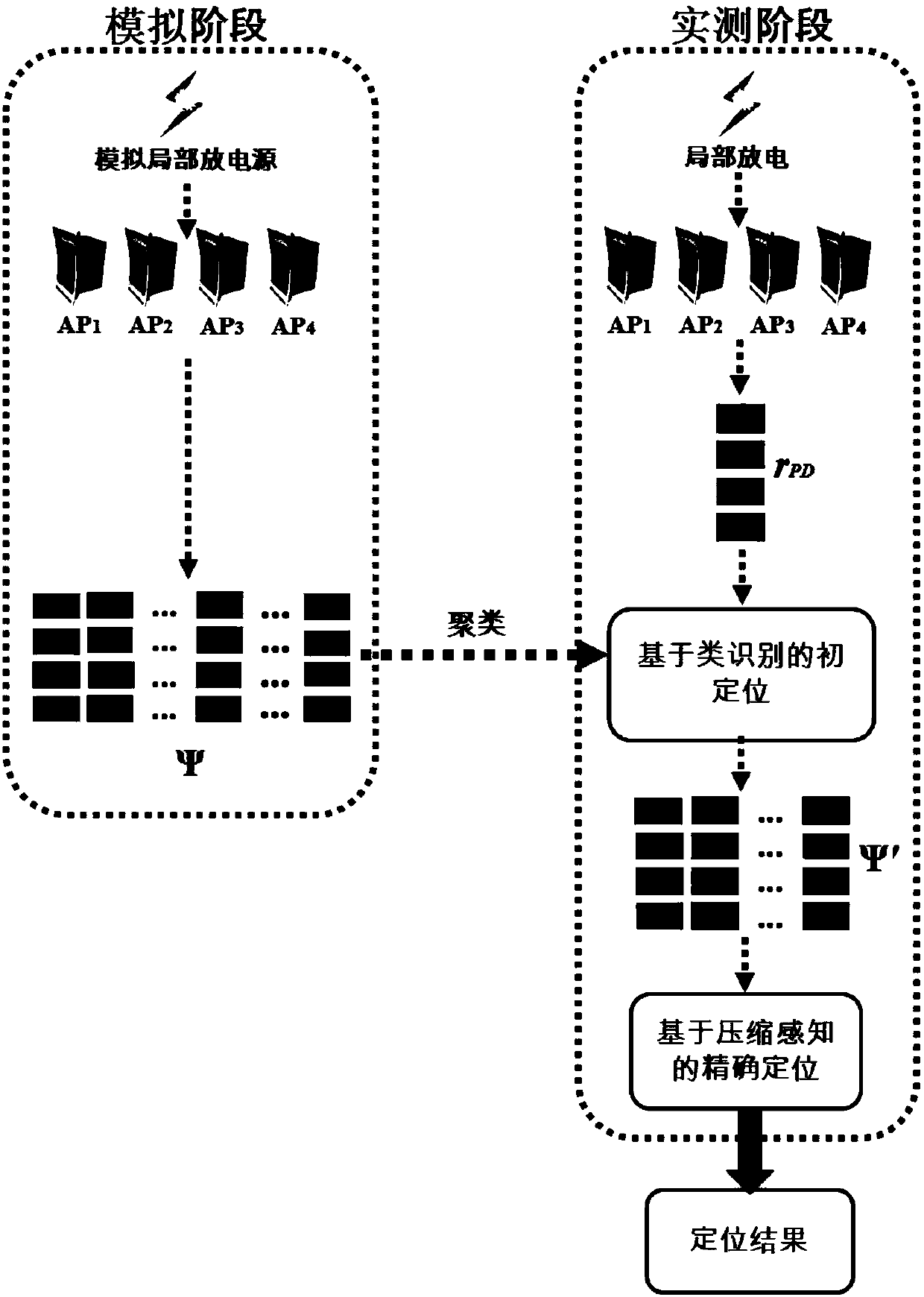

Partial discharge signal location method and system of two-stage substation

ActiveCN108490325ALower requirementReduce positioning costsTesting dielectric strengthDistribution characteristicPower equipment

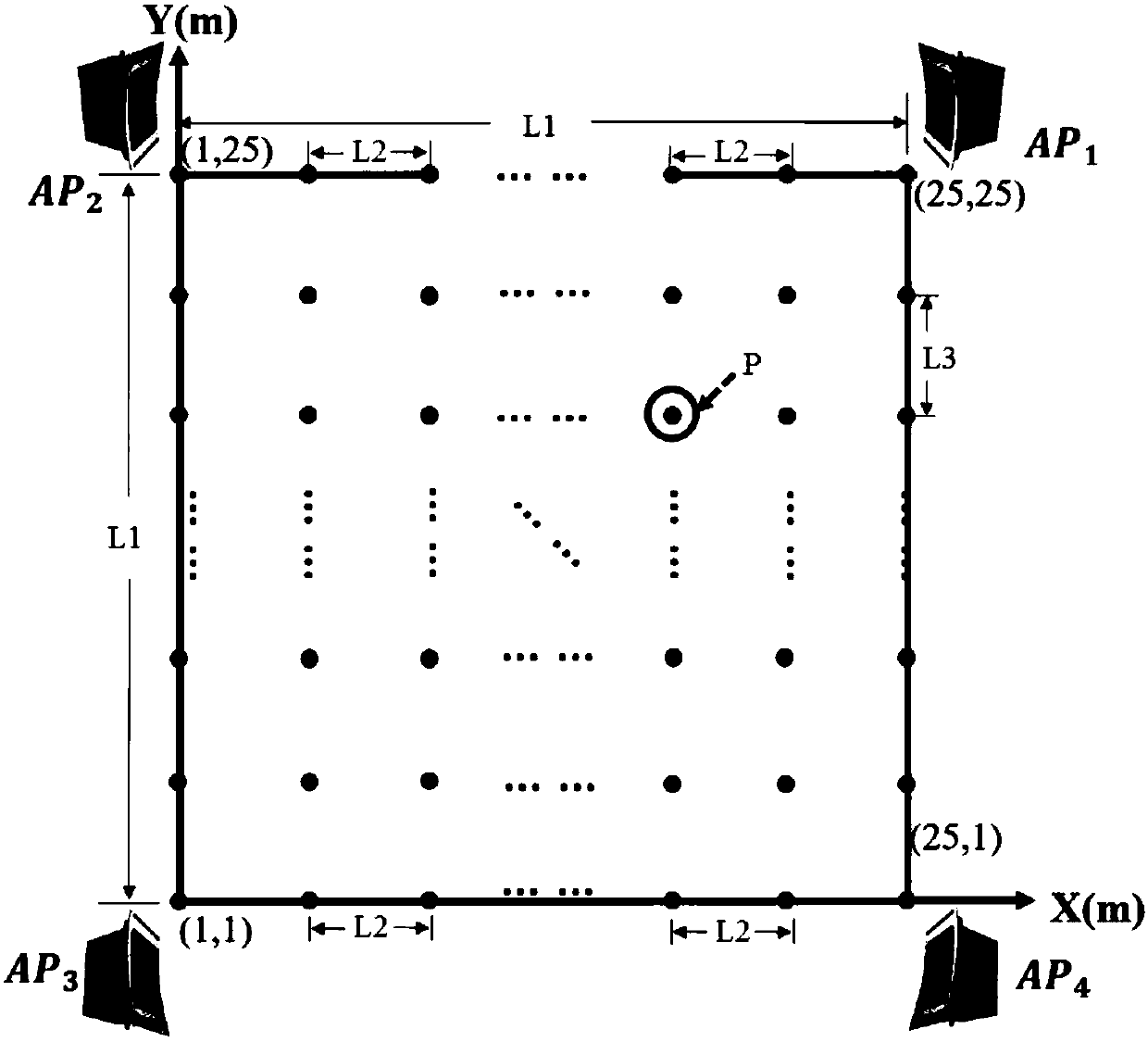

The invention discloses a partial discharge signal location method of a two-stage substation. The method comprises: step one, constructing a simulated partial discharge signal intensity distribution characteristic matrix tau; step two, carrying out clustering on simulated partial discharge intensity characteristic vectors in the simulated partial discharge signal intensity distribution characteristic matrix to obtain C classes; step three, collecting partial discharge signals by using n ultra-high-frequency sensors and acquiring corresponding practically measured partial discharge intensity characteristic vectors in a state of occurrence of partial discharging; step four, carrying out preliminary positioning on the partial discharge signals to reduce the positioning range; and step five, carrying out precise positioning on the partial discharge signals based on a compressed sensing algorithm. In addition, the invention also discloses a partial discharge signal location system of a two-stage substation. The location method and system have advantages of low measurement difficulty, low requirements on equipment hardware, and high positioning accuracy; and while the high positioning accuracy is ensured, the cost of power equipment is lowered.

Owner:SHANGHAI JIAO TONG UNIV

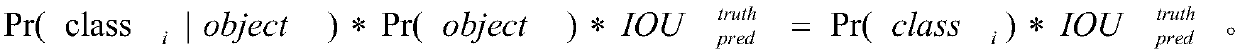

Target detection method of YOLO algorithm based on batch re-normalization processing

InactiveCN110334594AReduce training timeLower requirementCharacter and pattern recognitionNeural architecturesPattern recognitionVisual technology

The invention relates to a target detection method of a YOLO algorithm based on batch re-normalization processing, and belongs to the technical field of target detection and computer vision. The target detection method comprises the following steps: inputting an image with the size of 448 * 448 into a network structure detection model based on a YOLO algorithm; segmenting the image into S * S grids, wherein if it is judged that the center of the object falls on a certain grid, the grid is responsible for detecting the object; predicting the posterior probability that the detected object in charge of the grid belongs to a specific class in the C classes; predicting B target frames and confidence scores for each personal grid; and calculating the correlation confidence of the target frame class. According to the invention, the regional suggestion type target detection framework is reformed, and repeated work caused by overlapping of suggestion boxes is avoided, and the target detection speed is improved.

Owner:KUNMING UNIV OF SCI & TECH

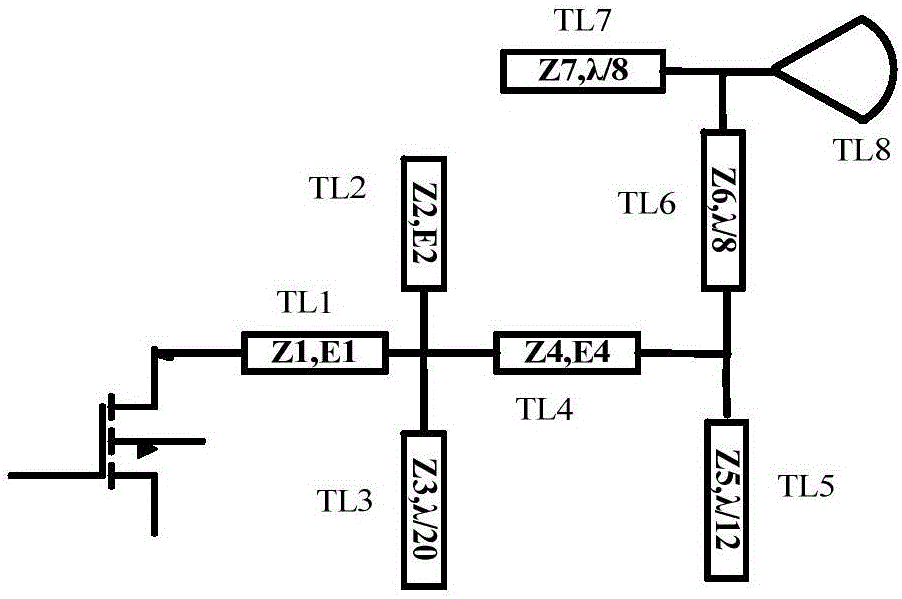

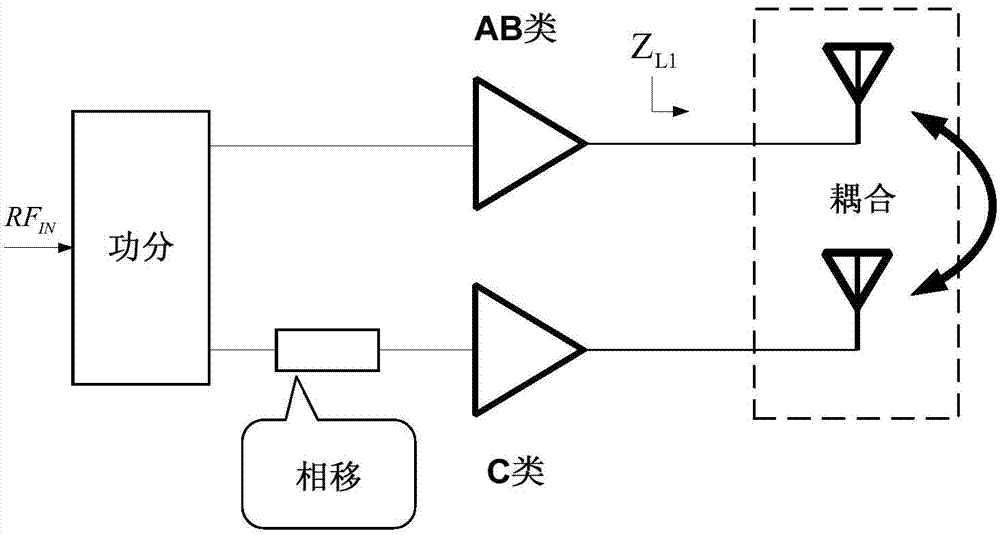

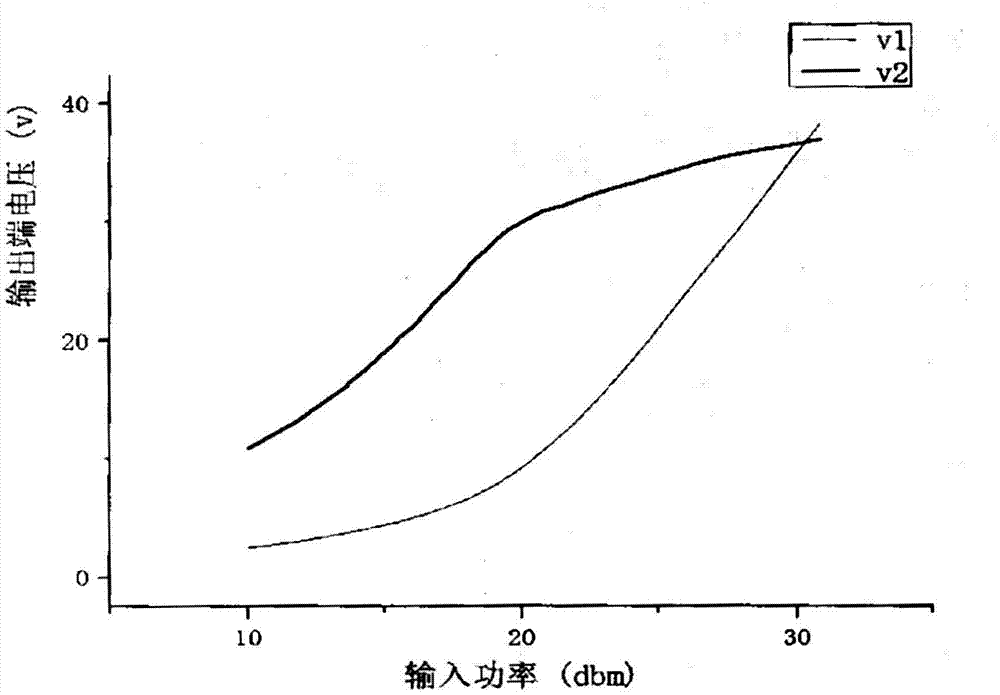

Active load modulation transmitter based on space coupling

ActiveCN103944623AEnables automatic active modulationImprove efficiencySpatial transmit diversityElectromagnetic couplingModulation function

The invention discloses an active load modulation transmitter based on space coupling and belongs to the field of radio frequency transmitters of the wireless communication technology. The transmitter is of a transmitter structure for completing the active load modulation function through coupling between antenna units of the transmitter and is respectively connected with a main path power amplifier, an auxiliary path power amplifier and corresponding transmitting antennae in the position of a power splitter, and thus two unit radiating antenna arrays are formed. To achieve the active load modulation characteristic, the main path power amplifier is set in the AB-class state in a biasing mode, the auxiliary path power amplifier is set in the C-class state in a biasing mode, and a phase shifter is connected between the power splitter and the auxiliary path power amplifier. The two unit radiating antennae are close to each other, and thus sufficient electromagnetic coupling between the radiating antenna units is achieved, and the load modulation purpose is achieved. Meanwhile, a quarter-wave impedance conversion element in a traditional Doherty power amplifier structure is omitted, the structure of the transmitter is simplified, and the efficiency and the bandwidth of the system are promoted.

Owner:TSINGHUA UNIV

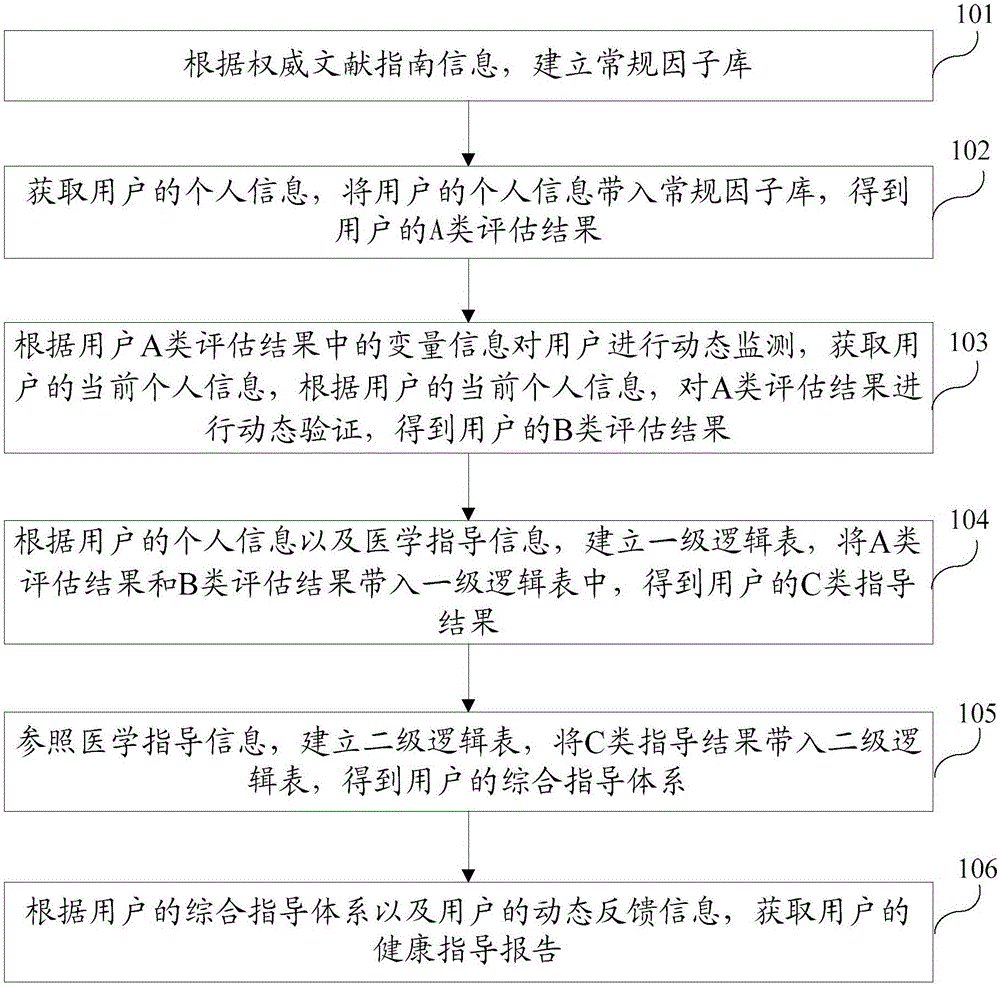

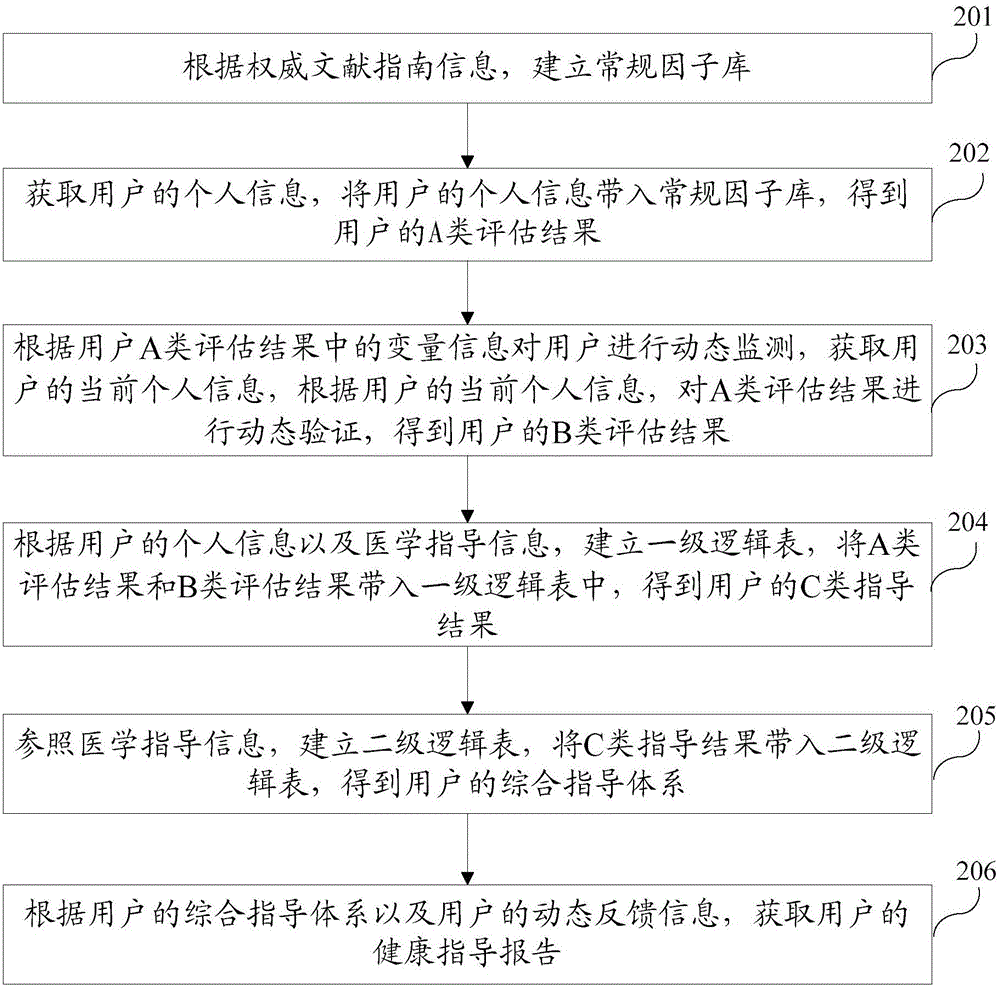

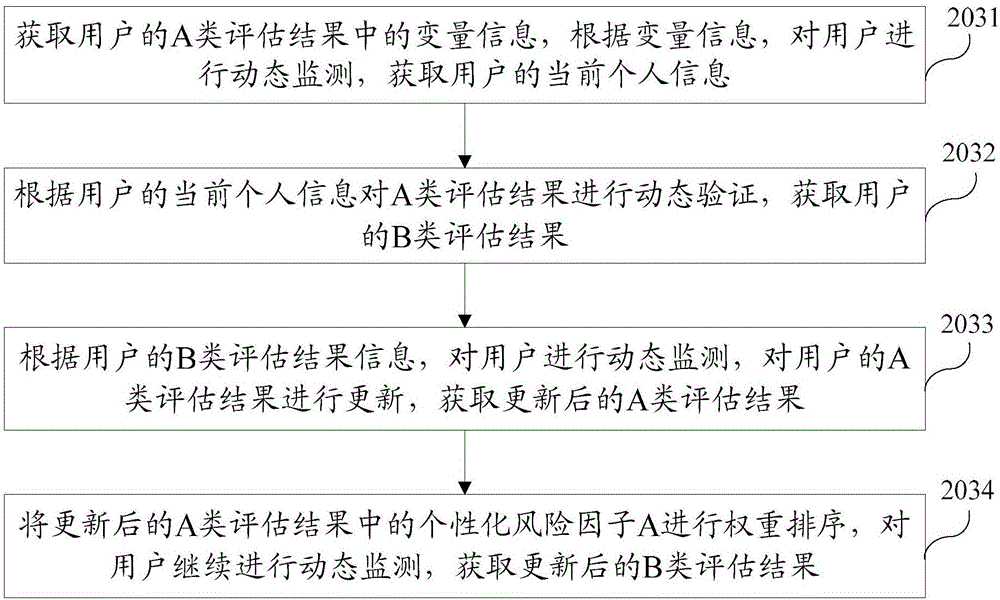

Personalized factor-based health assessment method

InactiveCN107526931AImprove accuracyImprove effectivenessSpecial data processing applicationsPersonalizationDynamic monitoring

The invention discloses a personalized factor-based health assessment method. The method comprises the steps of establishing a conventional factor library according to authoritative literature guide information; substituting personal information of a user into the conventional factor library to obtain an A class assessment result of the user, and according to variable information in the A class assessment result of the user, performing dynamic monitoring on the user to obtain a B class assessment result of the user; according to the personal information of the user and medical guide information, establishing a first-level logic table, and substituting the A class assessment result and the B class assessment result into the first-level logic table to obtain a C class guide result of the user; by reference to the medical guide information, establishing a second-level logic table, and substituting the C class guide result into the second-level logic table to obtain a comprehensive guide system of the user; and according to the comprehensive guide system of the user and dynamic feedback information of the user, obtaining a health guide report of the user. Through the method, the problems of low personalization and poor timeliness of existing health assessment are solved.

Owner:北斗云谷(北京)科技有限公司

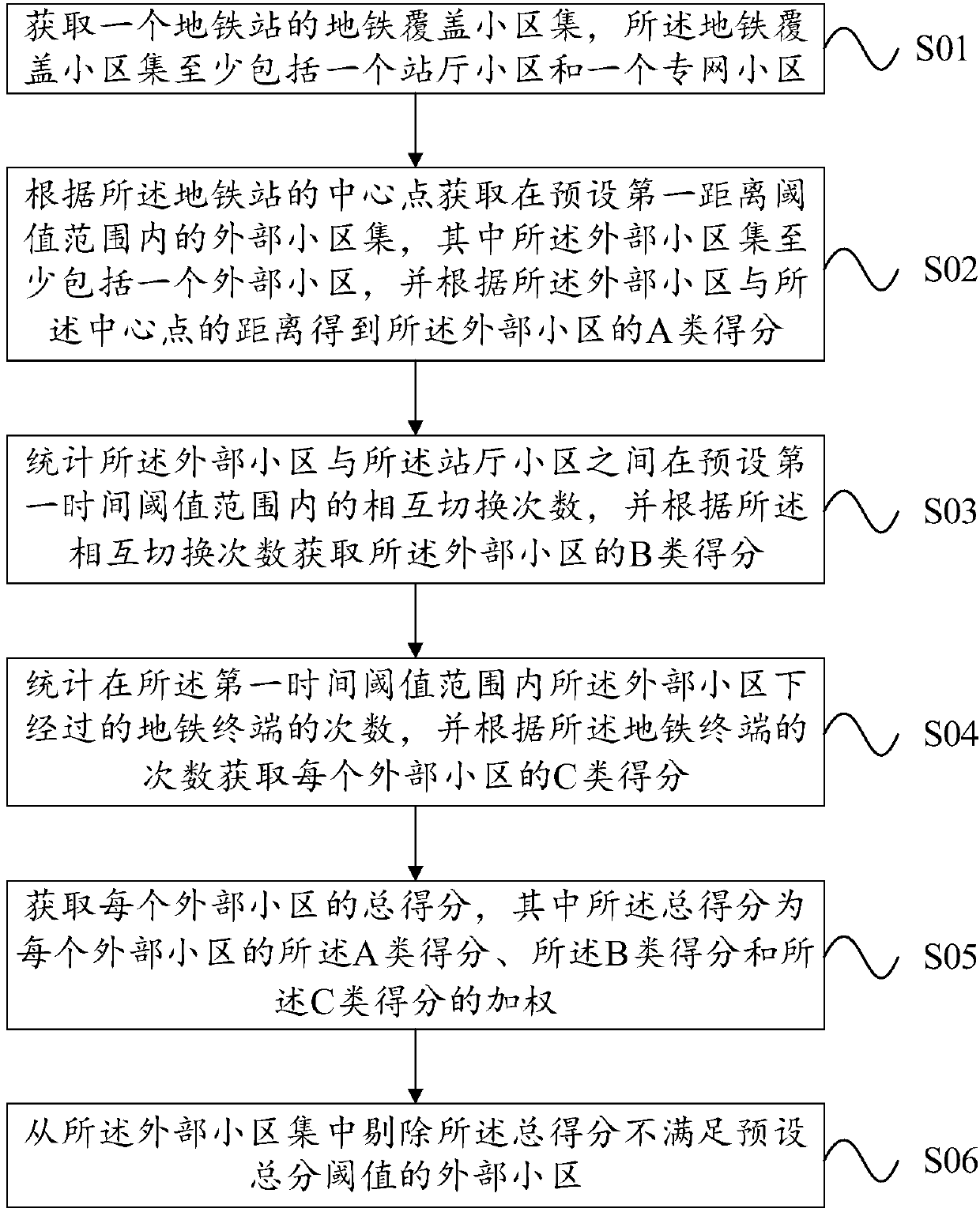

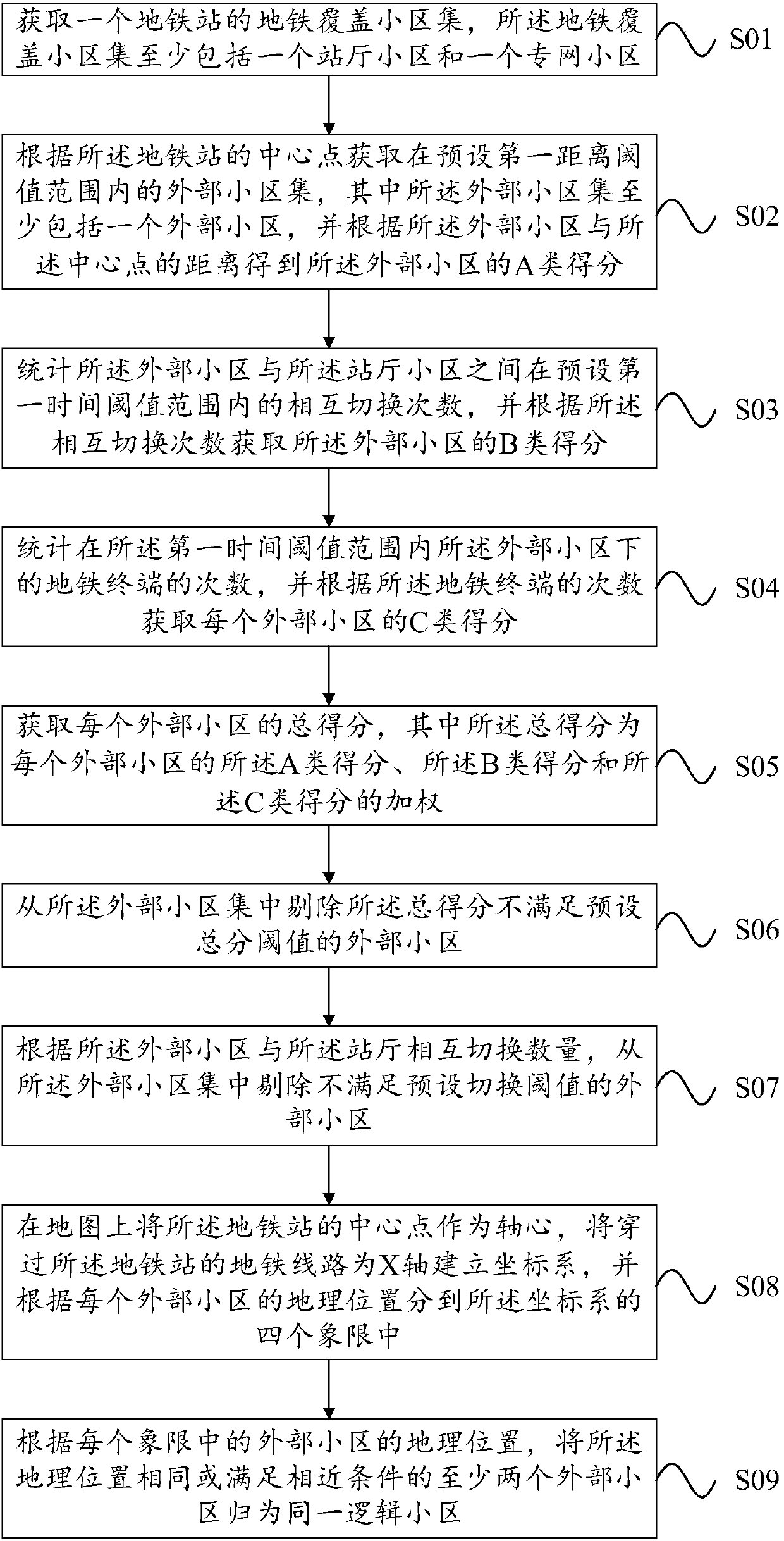

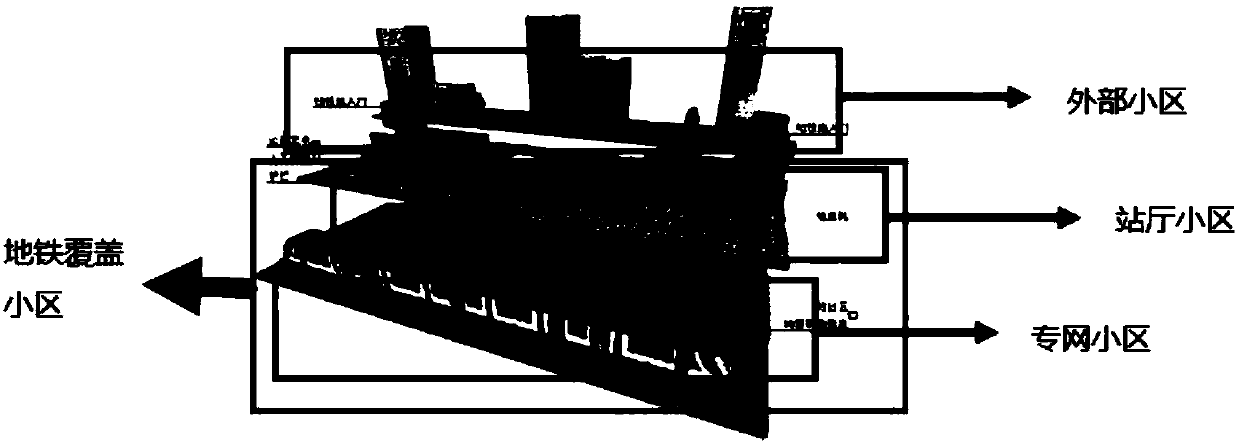

A metro network scene cell identification method and device

ActiveCN109699035AAccurate acquisitionEasy accessWireless communicationTelecommunicationsPrivate network

The embodiment of the invention provides a metro network scene cell identification method and device. The method comprises the following steps: obtaining a subway coverage cell set of a subway station, wherein the subway coverage cell set comprises a station hall cell and a private network cell; Obtaining an external cell set within a preset first distance threshold range according to the centralpoint of the subway station, and obtaining an A type score according to the distance between the external cell and the central point; Counting the number of times of mutual switching between an external cell and the station hall cell within a preset first time threshold range, and obtaining a class B score of the external cell; Counting the number of times of passing through the subway terminal under the external cell within a first time threshold range, and obtaining a C-class score of each external cell; Obtaining a total score of each external cell; According to the embodiment of the invention, the external cells near the subway station are scored through three dimensions, so that the external cells of the subway station can be acquired more accurately, quickly and conveniently.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

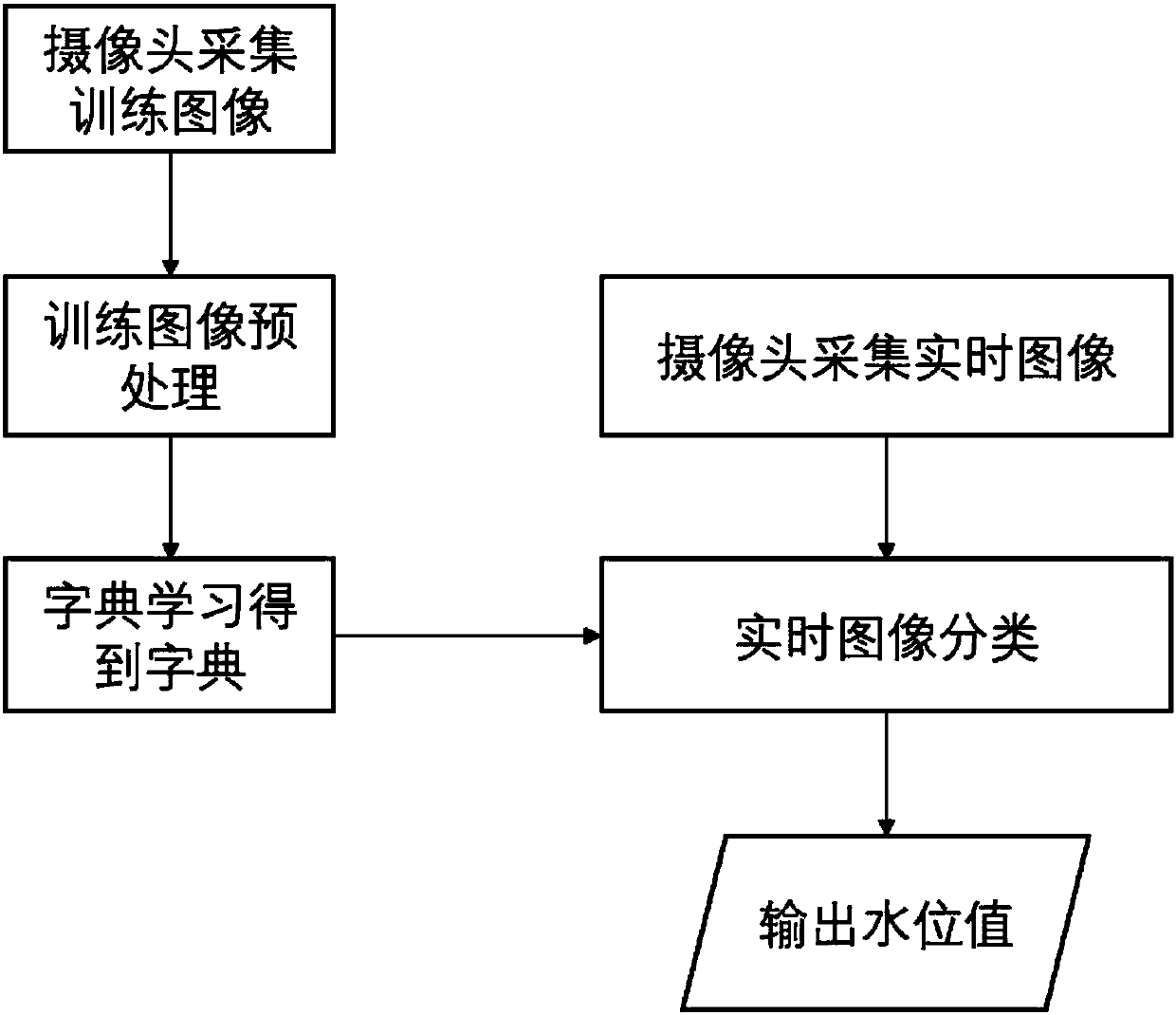

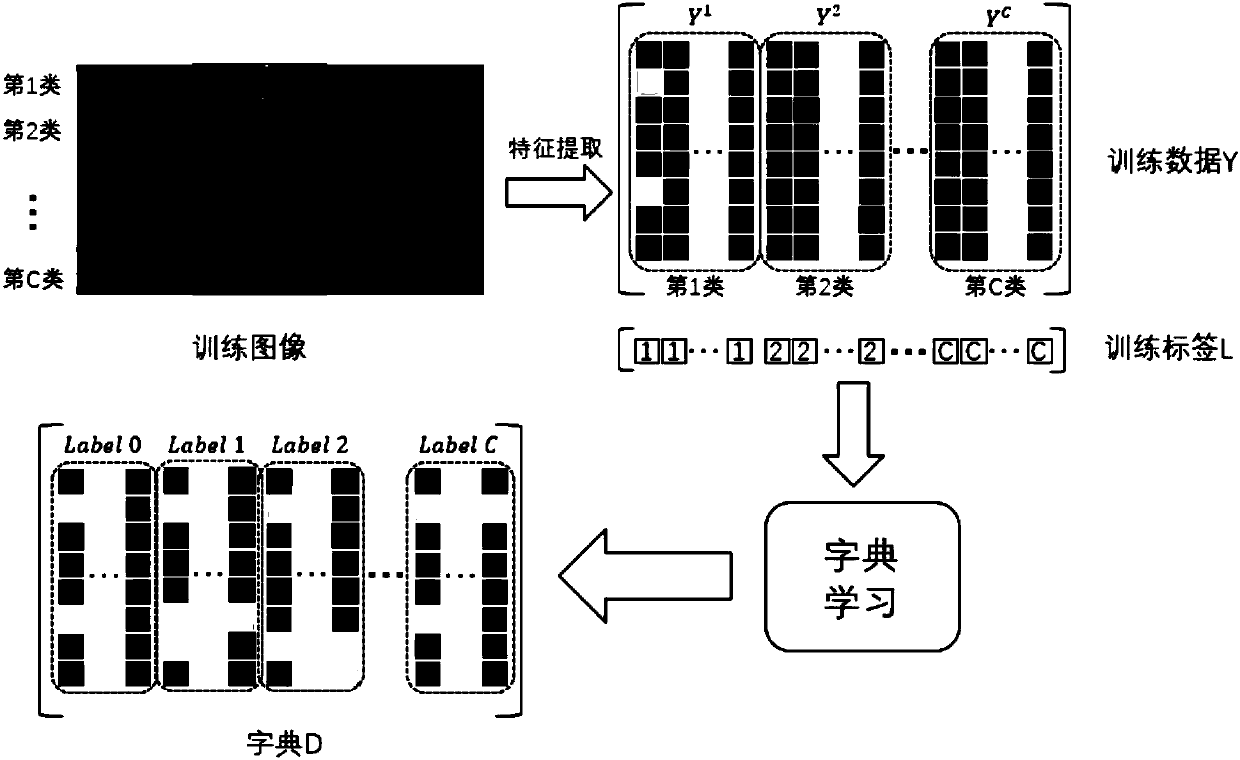

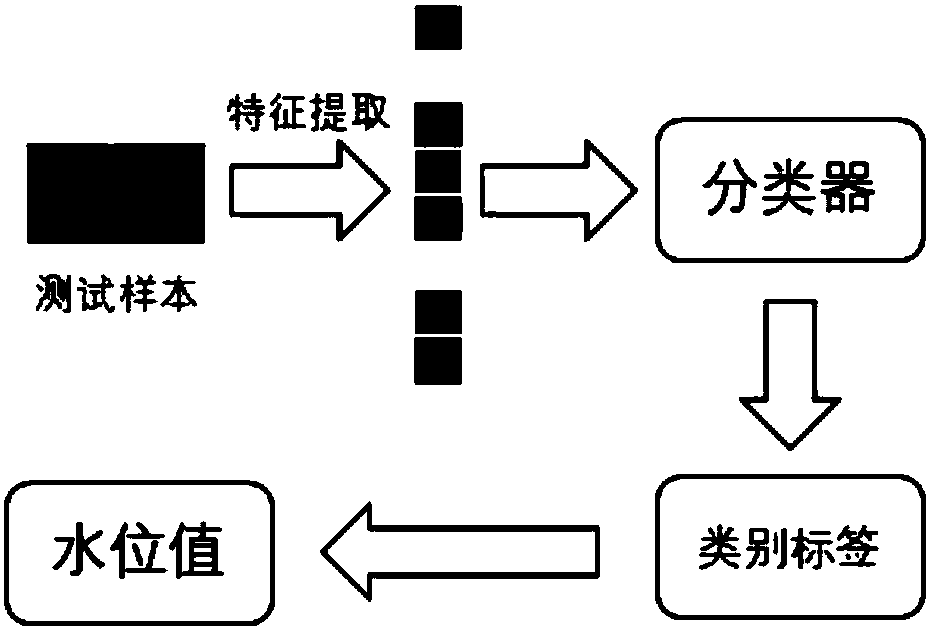

Water level monitoring method based on dictionary learning

ActiveCN108509980AAccurate identificationOvercoming Difficult to Accurately Identify ProblemsLevel indicators by dip membersCharacter and pattern recognitionDictionary learningSlide window

The present invention discloses a water level monitoring method based on dictionary learning. The method comprises the following steps of: the step 1, fixing a measuring rod at a river area to be measured, and collecting images of the measuring rod and areas near the water surface in real time through a camera; the step 2, collecting a plurality of images as training images, dividing each image into C classes, employing a sliding window to collect training data for each class of image blocks, and marking corresponding class tags; the step 3, employing a dictionary learning method to perform training of the training data to obtain a dictionary D; and the step 4, employing the dictionary D to perform real-time classification of the images collected by the camera to obtain class tag vectors of the images so as to obtain a water level value. The water level monitoring method can be achieved only through installation of a traditional rod so as to overcome the problem that the horizontal plane position is difficult to accurately identify in a traditional water level measurement scheme, and has high stability and robustness.

Owner:NANJING UNIV OF POSTS & TELECOMM

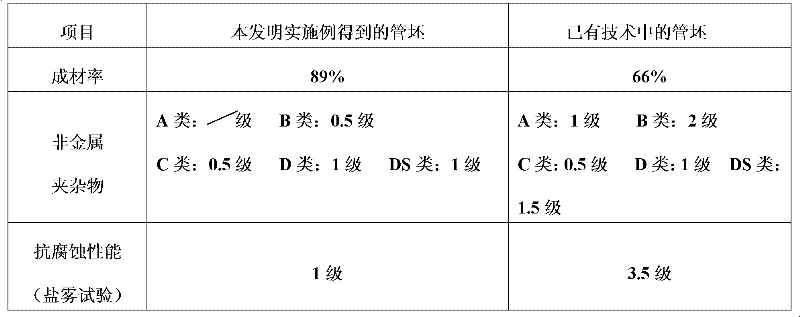

00Cr18Mo2 stainless steel pipe billet and manufacture method thereof

The invention discloses a 00Cr18Mo2 stainless steel pipe billet and a manufacture method thereof, which belong to the technical field of stainless steel materials. The 00Cr18Mo2 stainless steel pipe billet comprises the following components: 0.01-0.025wt% of C, 0.15-0.35wt% of Si, 0.22-0.45wt% of Mn, 0.023-0.030wt% of P, 0.002-0.015wt% of S, 18.00-19.50wt% of Cr, 1.70-2.50wt% of Mo and the balance of Fe. The 00Cr18Mo2 stainless steel pipe billet has the advantages of excellent corrosion resistance, low brittle transition temperature and good adaptability and can be applied to a generator set cooled by sea water, and resource is saved. Because the provided manufacture method has few technical steps, energy can be saved because the 00Cr18Mo2 stainless steel pipe billet does not need to be heated by electricity energy for multiple times. The manufacture method is favorable for the content of O2, N and C so as to control the content of harmful chemical elements. The non-metal inclusion in the obtained pipe billet can reach B-class 0.5 grade, C-class 0.5 grade, D-class 1 grade and DS class 1 grade. The yield rate is above 89%.

Owner:常熟市长江不锈钢材料有限公司

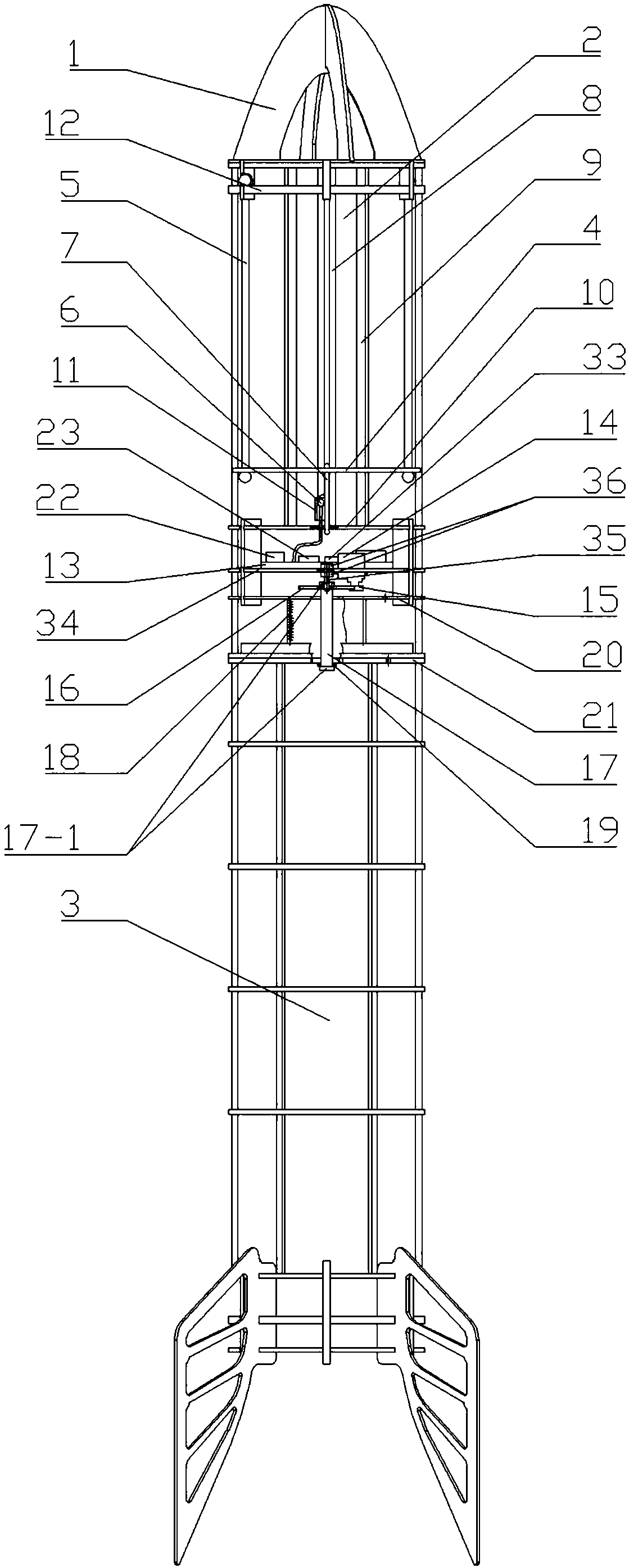

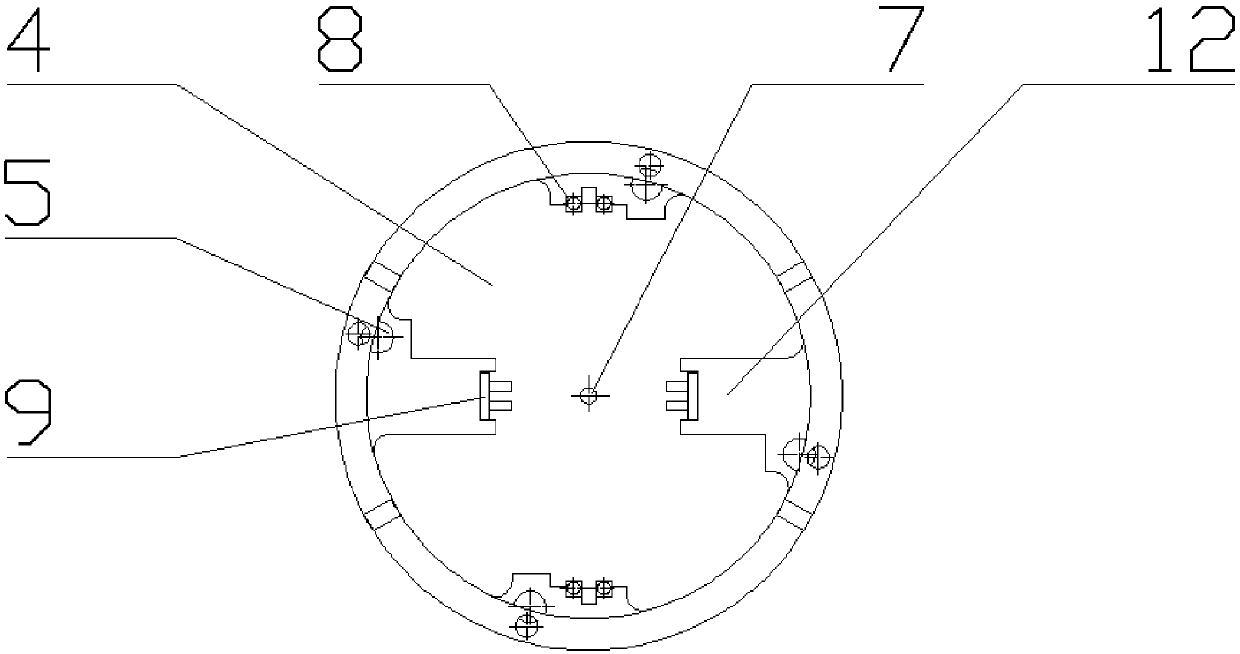

Inertial navigation-based fast response rocket delivery system and delivery method

ActiveCN107678332AExtensive researchBroad development prospectsProgramme controlComputer controlTerrainFlight time

The invention relates to an inertial navigation-based fast response rocket delivery system and delivery method. With the inertial navigation-based fast response rocket delivery system and delivery method of the invention adopted, the problems of low loading capacity, short flight time, high cost per unit, requirements for high operation level of operators and insufficient reconnaissance on the ground of an existing unmanned aerial vehicle delivery system and the problems of low control precision and poor cross-country capacity of ground reconnaissance cars of an existing rocket delivery systemcan be solved. The system of the invention includes a nose cone, a loading module, a propulsion module and an all-terrain crawler. The flight process of the delivery system of the present invention can be completed in less than one minute; and a process from the assembly of the system to the completion of a mission can be completed within five minutes; the propulsion module designed in the systemof the invention can be configured with 19 C-class engines at most; the maximum load of the loading module can reach 2KG; and the cost of the system of the present invention is 600 yuan which is muchlower than the cost of several thousands of yuan of mainstream unmanned aerial vehicles on the market at present. The delivery system and delivery method of the invention can be used for the materialdelivery and remote reconnaissance field.

Owner:HARBIN INST OF TECH

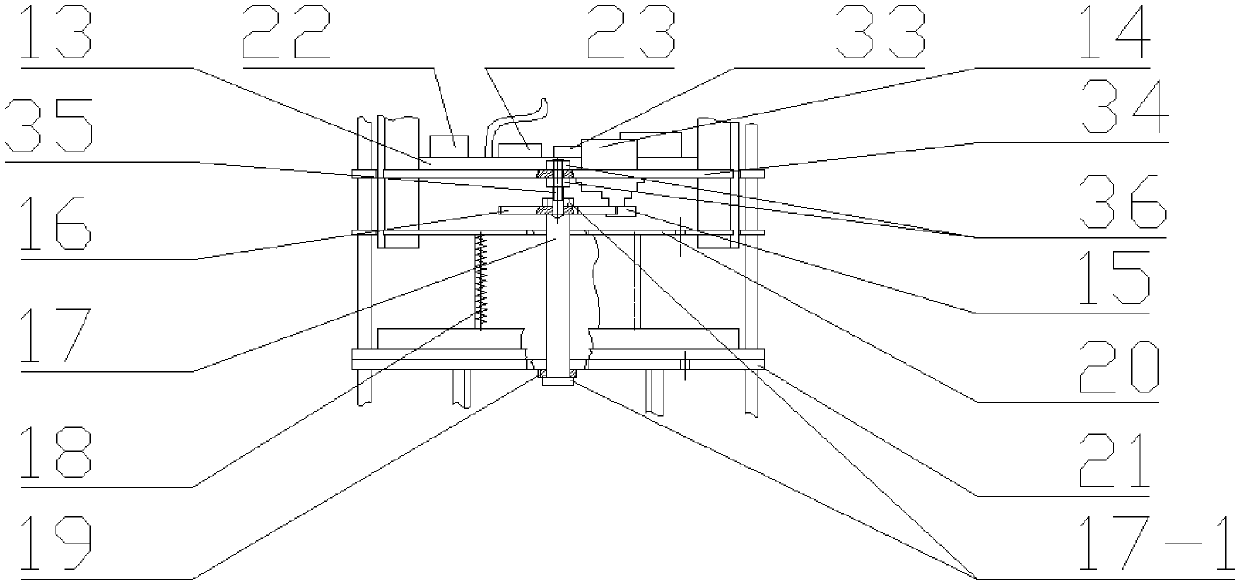

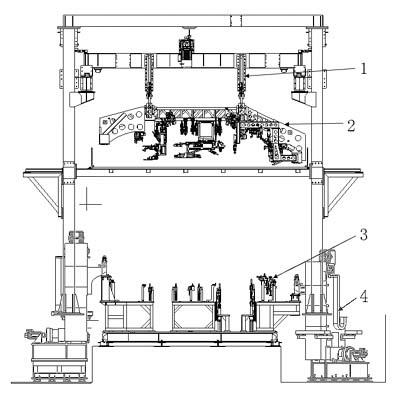

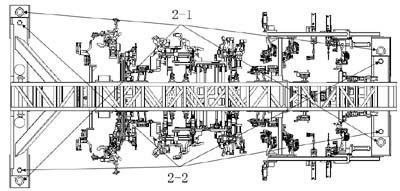

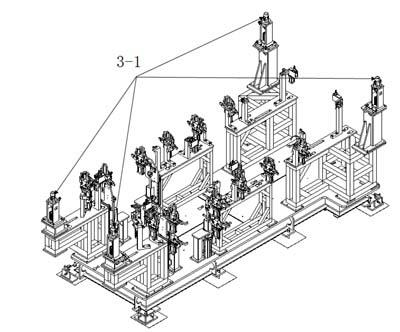

Built-in main fixture

InactiveCN102463436AGuaranteed dimensional accuracyReduced dimensional accuracyWelding/cutting auxillary devicesAuxillary welding devicesProduction lineMixed flow

The invention relates to a built-in main fixture. The built-in main fixture consists of a lower vehicle body positioning fixture, a built-in fixture body, a lifting system and a switching system. The built-in main fixture is characterized in that: a four-point positioning mode is adopted between the built-in fixture body and the lower vehicle body positioning fixture, and the centers of four positioning points are positioned in the center of gravity of the built-in fixture body so as to ensure that the positioning error is furthest eliminated in the positioning process; and two round hook pins and two rhombic hook pins are arranged on the four positioning points, and achieve a guiding effect in the descending process of the built-in fixture body so as to eliminate the positional deviation generated in the descending process. When the built-in fixture body descends to the appropriate position, the hook pins position the built-in fixture body, so that the fit precision between the built-in fixture body and the lower vehicle body fixture is ensured to be within + / -0.05mm. The built-in main fixture can stably and quickly ascend and descend, and can better ensure the dimensional accuracy of a vehicle body; meanwhile, a complete set of built-in fixture switching mechanism can also realize the multi-vehicle-type mixed flow production, and the switching time between vehicle types is short, so that the production beat is promoted. The cost and period of the retrofit of a production line during the replacement of new and old vehicle types are reduced; and a split structure of the built-in main fixture can better control the dimensional accuracy of the vehicle body, so that the aim of producing C class high-end cars is fulfilled.

Owner:FAW GROUP +1

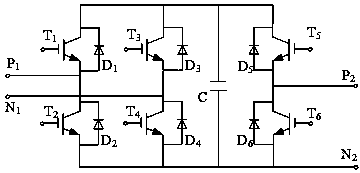

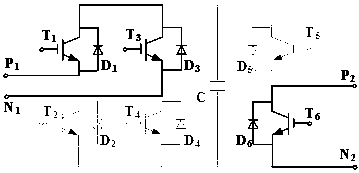

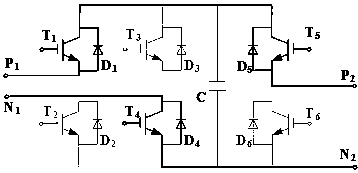

Novel two-port hybrid half-full bridge sub-module MMC topology

InactiveCN107769598AGuaranteed DC Fault Clearance CapabilityAc-dc conversionFull bridgeComputer module

The invention provides a novel two-port hybrid half-full bridge sub-module (Hybrid Half-Full Bridge Sub-module, H-HFBSM) MMC topology. The novel topology comprises two classes of two-port sub-modulesA (A-Class Sub-module, A-SM) and B (B-C class Sub-module, B-SM), wherein the B-class sub-module is obtained by turning over the A-class sub-module, and an extra group of insulated gate bipolar transistors (IGBT) and a reverse parallel diode are additionally arranged in each A-class sub-module to ensure that two poles of a capacitor cannot be connected to automatically discharge. In the field of power transmission and distribution, an MMC is formed by connecting novel hybrid half-full bridge sub-modules in series. The topological matching control mode has all functions and fault crossing capability of a conventional MMC sub-module (such as full-bridge sub-module) and also has local automatic voltage sharing capability and higher current through capability, so that the demand on capacitanceof the capacitor can be reduced on the same voltage ripper amplitude of the capacitor.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

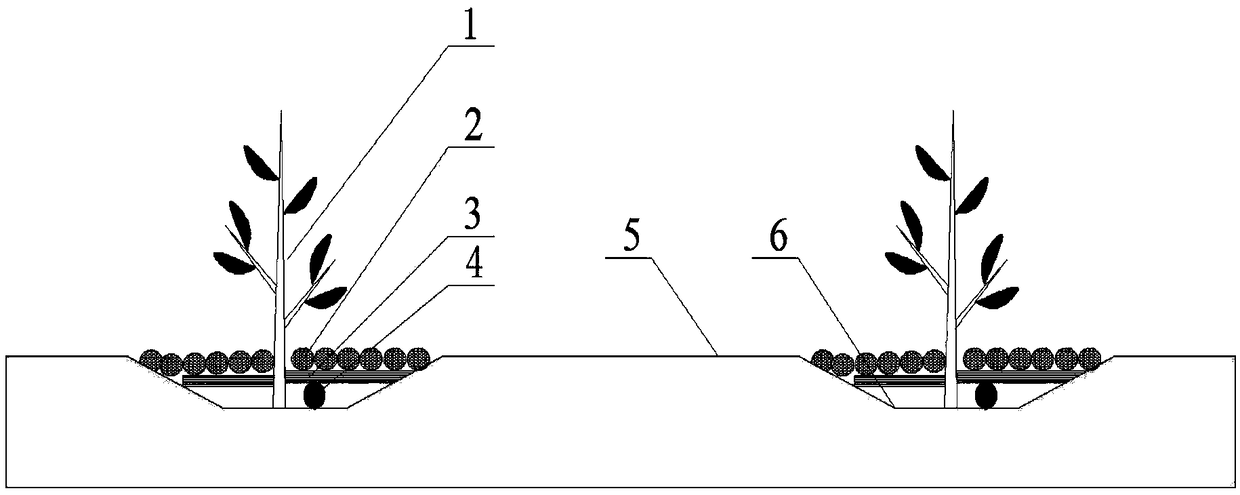

Wolfberry drip irrigation cultivation method achieving double-layer cross straw covering

ActiveCN108934723AReduce wasteIncrease profitFertilising methodsCultivating equipmentsDrip irrigationSystem optimization

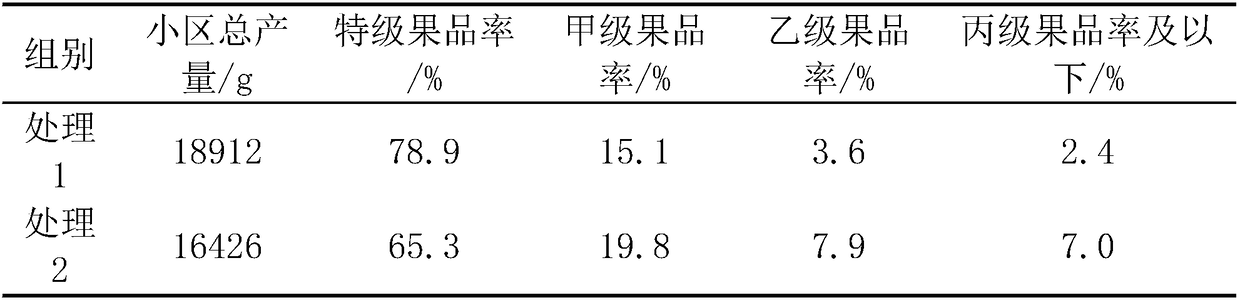

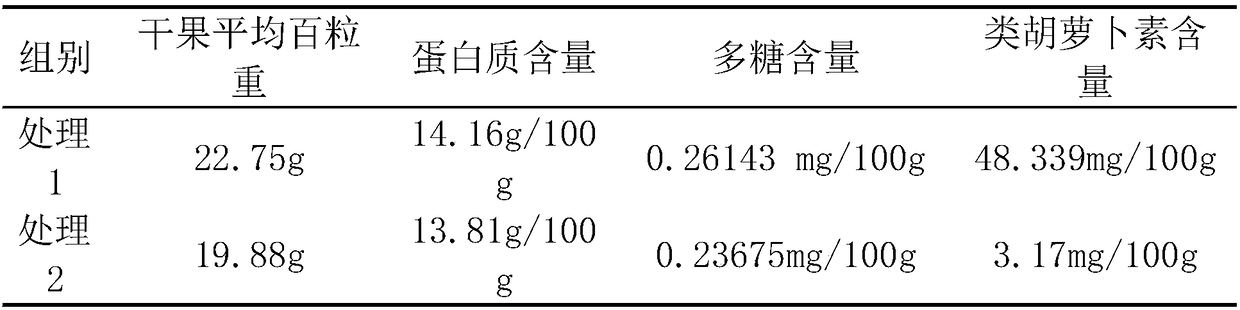

The invention discloses a wolfberry drip irrigation cultivation method achieving double-layer cross straw covering, and belongs to the technical field of water saving drip irrigation cultivation in arid and semi-arid regions. According to the water saving drip irrigation method, aiming at soil and climate characteristics in the arid and semi-arid regions, by adopting the measures of wolfberry cutting seedling treatment, efficient furrow rainwater collection, drip irrigation cultivation in a furrow, drip irrigation system optimization and double-layer cross covering of crushed wheat straw and corn straw, the rainfall and irrigation water utilization rate is increased, and invalid waste of the water resource is reduced. Compared with a traditional wolfberry flood irrigation cultivation method, the total output is increased by 15.13%, the super fruit rate is increased by 13.6%, a C-class fruit rate is lowered by 4.6%, and the dry fruit average hundred-grain weight is increased by 14.44%;the protein content is increased by 2.53%, the polysaccharide content is increased by 10.42%, and the carotenoid content is increased by 45.169 mg / 100 g.

Owner:GANSU AGRI UNIV

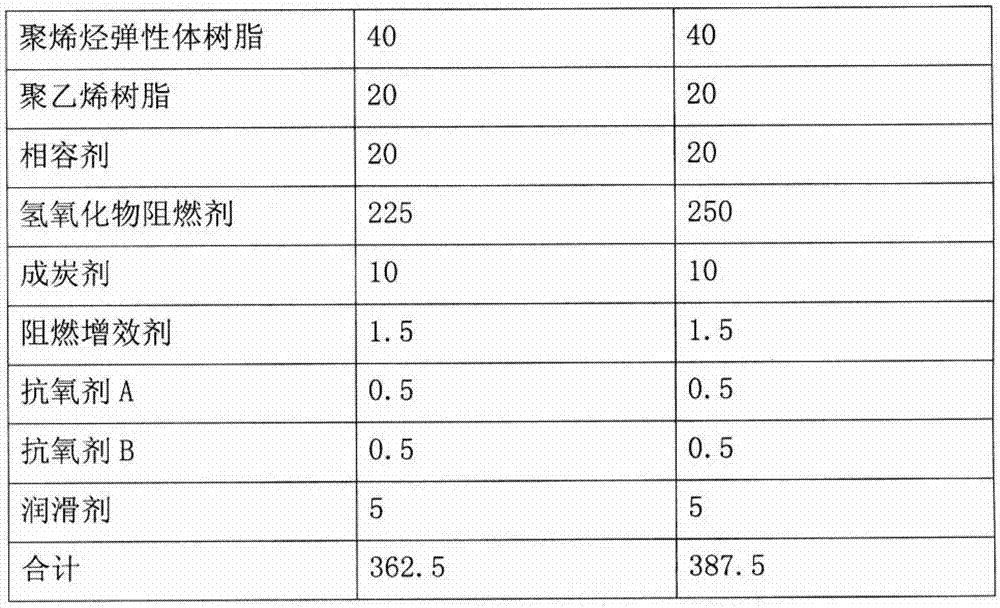

Thermoplastic low-smoke halogen-free high-flame-retardant polyolefin sheath material and preparation method thereof

InactiveCN106928532AGood dispersionNot easy to fall offPlastic/resin/waxes insulatorsInsulated cablesElastomerThermoplastic

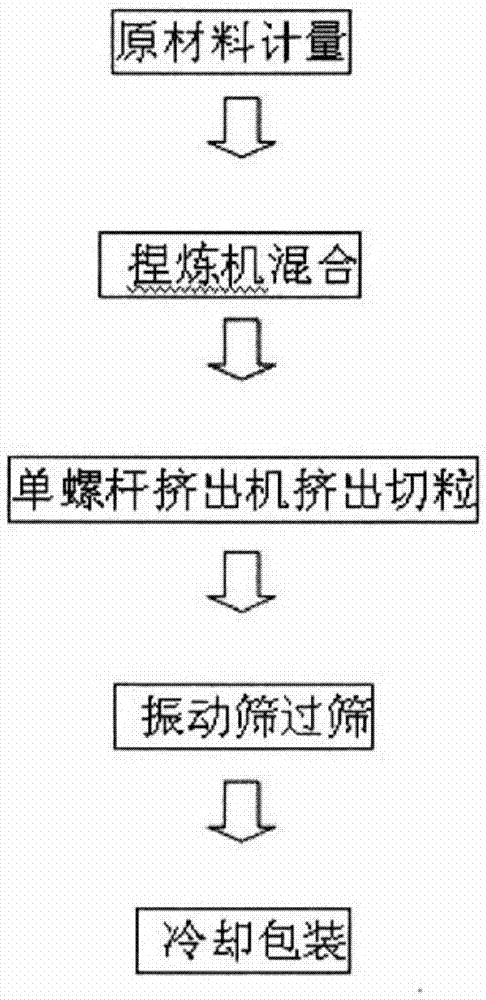

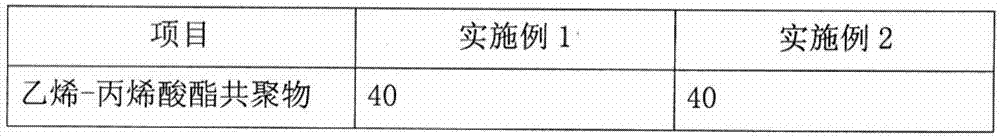

The invention provides a thermoplastic low-smoke halogen-free high-flame-retardant polyolefin sheath material and a preparation method thereof. The material is mainly prepared from, by weight, 30-40 parts of ethylene-acrylate copolymer resin, 30-40 parts of polyolefin elastomer resin, 20-30 parts of polyethylene resin, 10-20 parts of compatilizer, 200-250 parts of hydroxide flame-retardant agent, 5-10 parts of charring agent, 1-2 parts of flame-retardant synergist, 0.5 part of antioxidant A, 0.5 part of antioxidant B and 5-10 parts of lubricating agent. The preparation method includes the steps that the raw materials are metered by weight and conveyed into a mastication machine to be evenly mixed, the mixture is conveyed into a single-screw extruder to be extruded and granulated, then the mixture is screened through a vibrating sieve, and finally the mixture is cooled and packaged to obtain the finished product. The preparation method is reasonable in design, the sheath material is high in oxygen index, has the environment-friendly characteristics of low fuming and low corrosion, is good in char forming characteristic and can be used as a digital communication cable sheath meeting the IEC332-3 bundling C class combustion test requirement, the preparation method is reasonable, and operation is easy.

Owner:天津市普立泰高分子科技有限公司

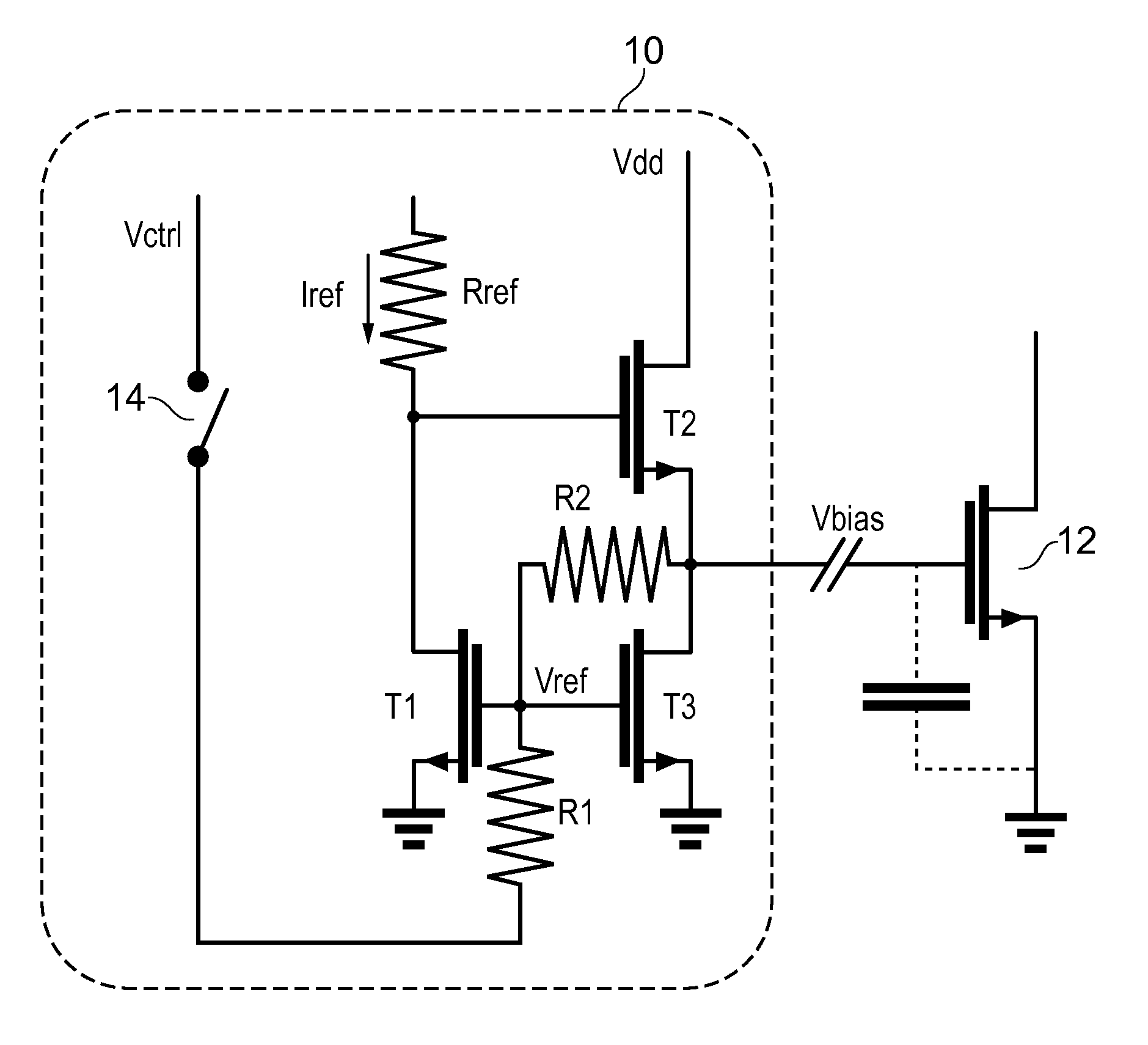

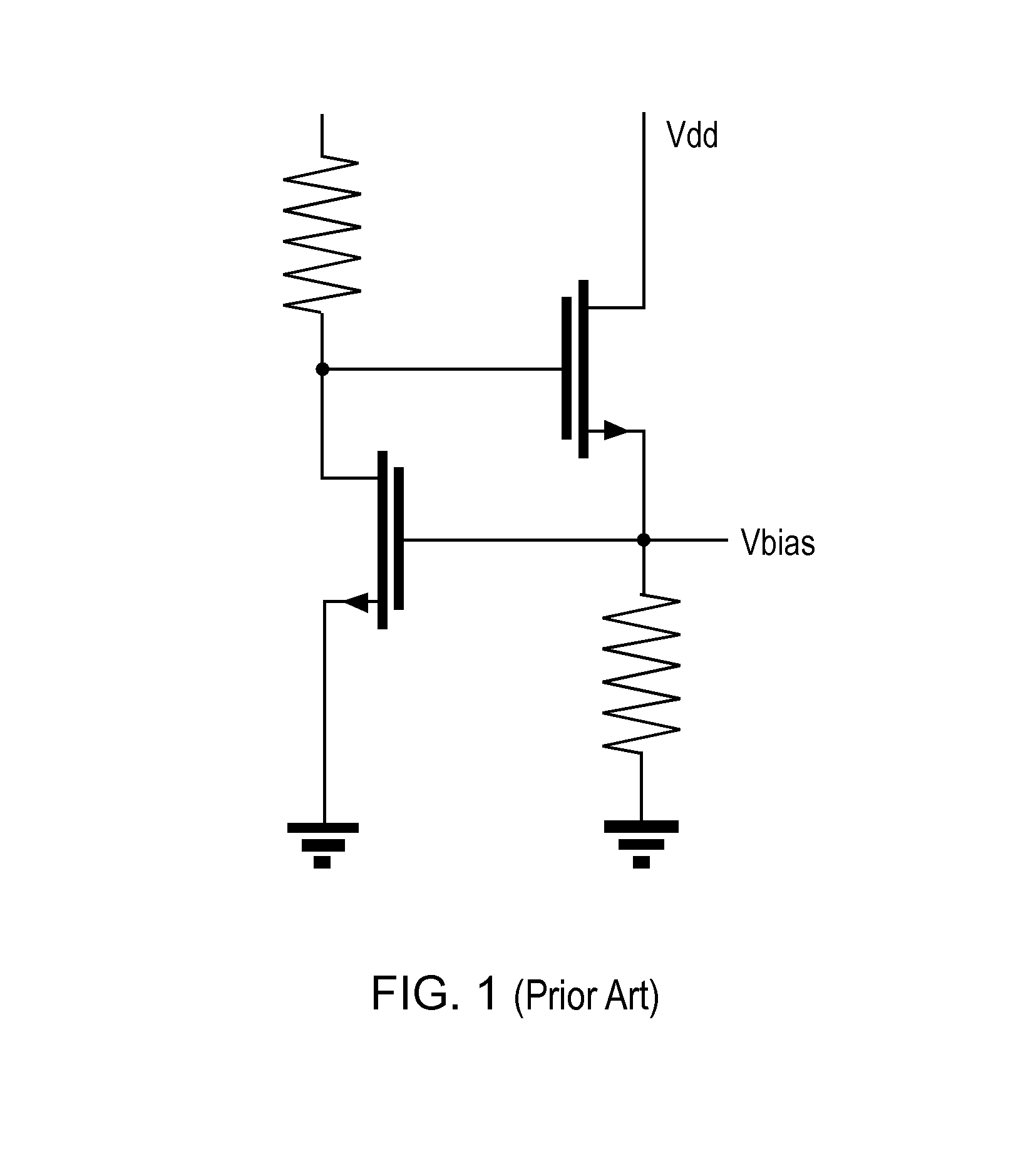

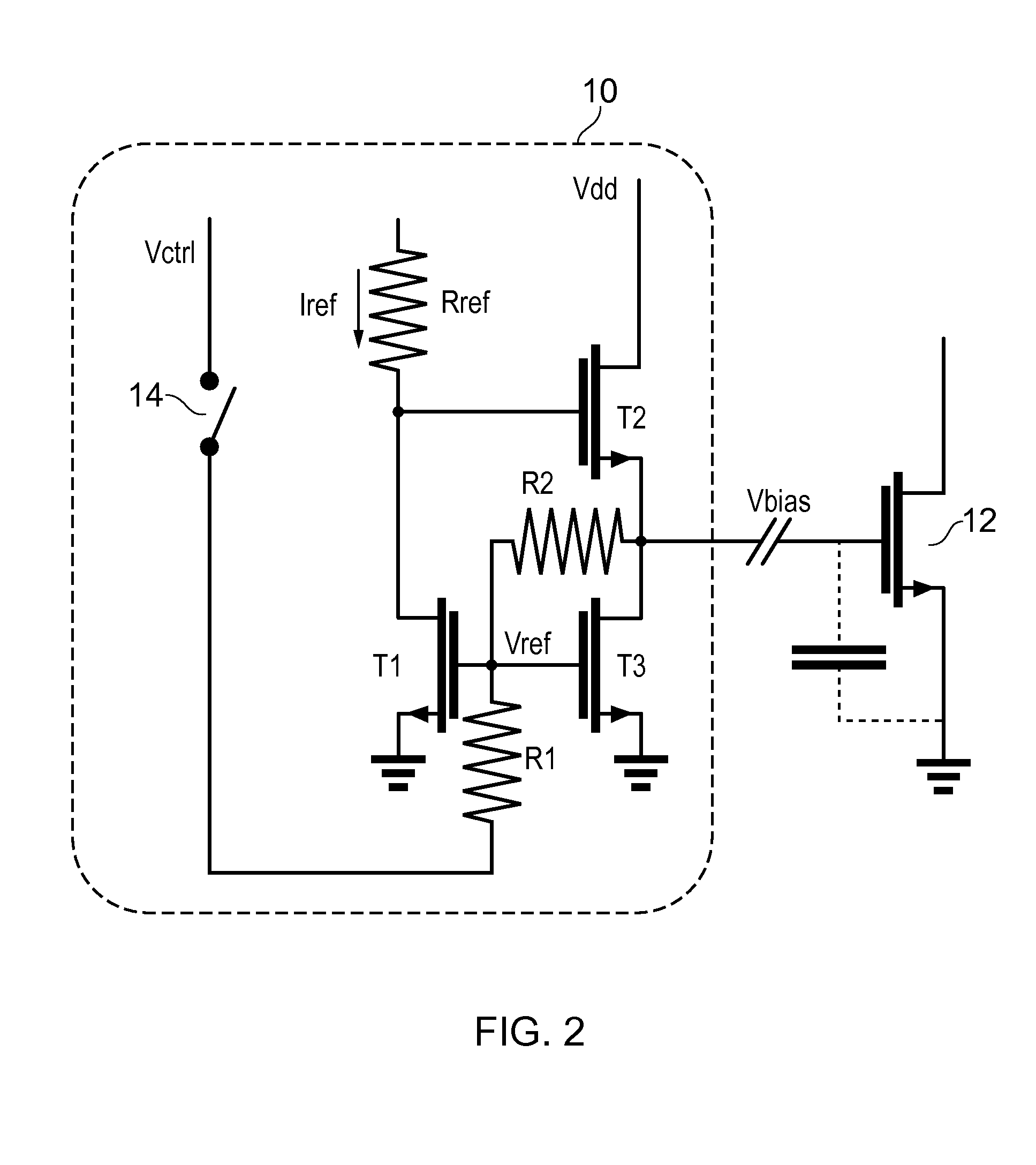

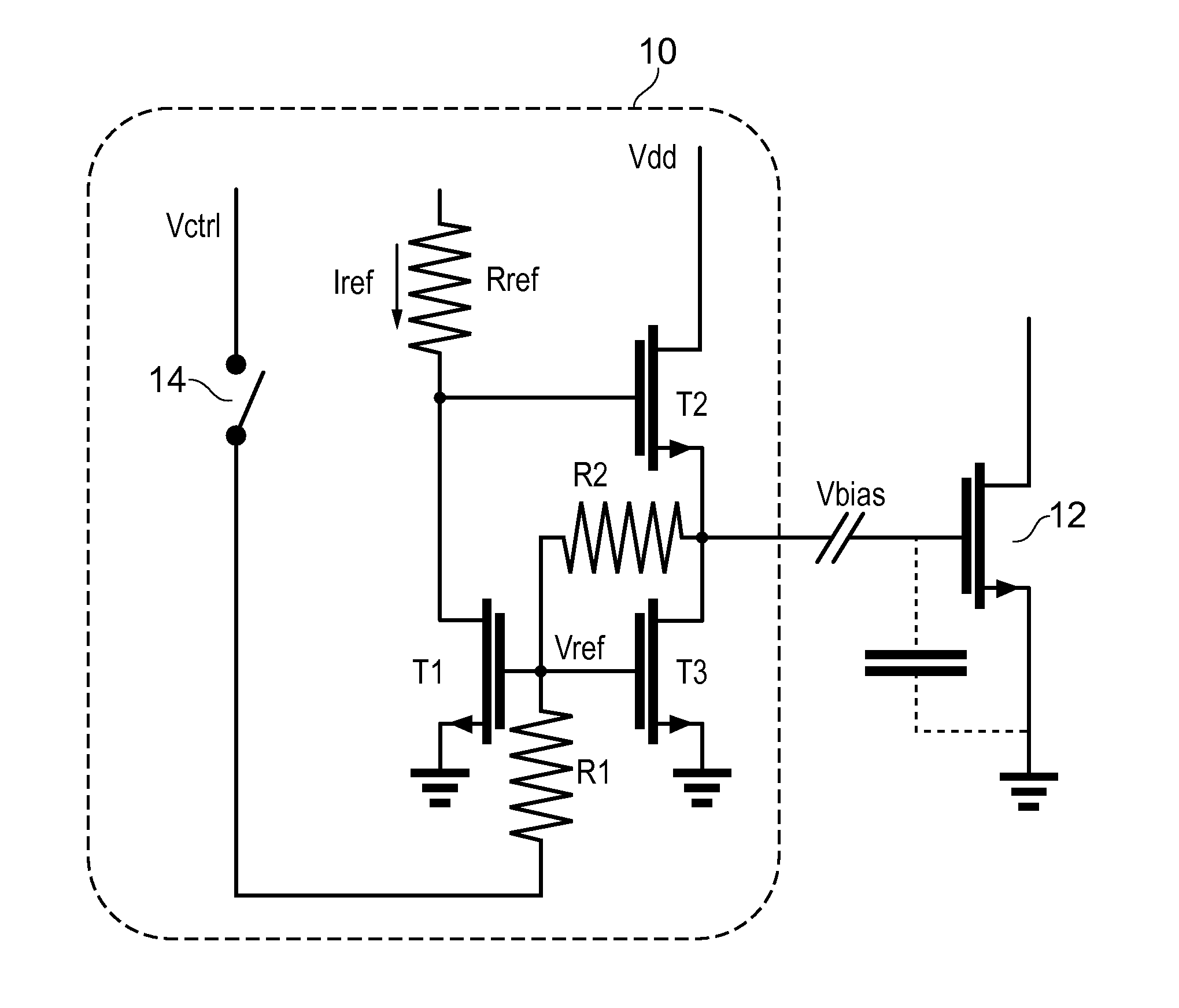

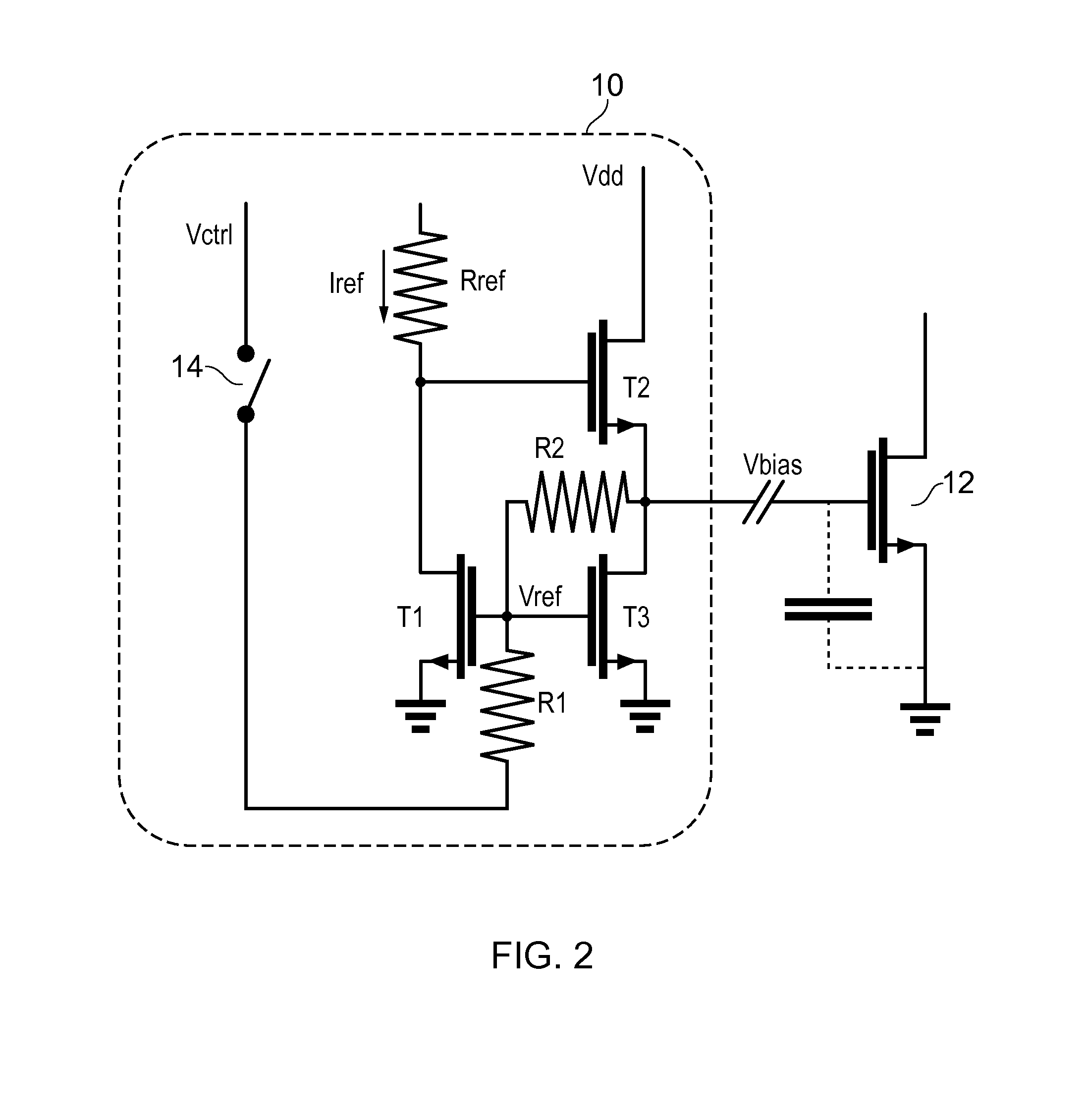

Bias circuit

ActiveUS8854143B2Small sizeFast trackHigh frequency amplifiersGain controlAudio power amplifierVoltage reference

Owner:AMPLEON NETHERLANDS

Method capable of reducing strip steel edge shearing amount

ActiveCN107626971AHigh yieldReduce wasteShearing machinesShearing machine accessoriesProduction lineAutomatic control

The invention relates to a method capable of reducing strip steel edge shearing amount. The method is suitable for the cold rolled silicon steel production and comprises the steps that rolling mill offline steel coil edge crack defect conditions are classified; secondly, a single-side shearing method is adopted in the edge crack defects of the A class to achieve edge shearing; thirdly, a non-equal-side shearing method is adopted in the edge crack defects of the B class and the C class; fourthly, in the cold rolling mill strip penetrating process, the positions of a deviation correcting rollerand the strip steel are adjusted to coincide with the central position of a production line; fifthly, when a cold rolling mill begins to start, the strip steel runs at the low speed, measuring is carried out multiple times, when it is found that the edge shearing amount is not even, a device is manually deviated in time to achieve adjustment, and in addition, tension of the rolling in the specialcondition is controlled. According to an automatic control system of an edge shear unit, the method that the dual-side edge shearing manner is adopted to achieve set value inputting, according to actual needs, and manual adjustment is achieved is adopted, the strip steel minimum shear amount is achieved, the product yield is improved, and the production cost is reduced.

Owner:ANGANG STEEL CO LTD

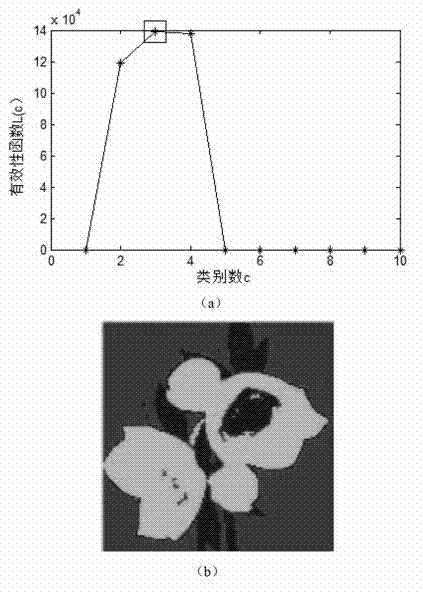

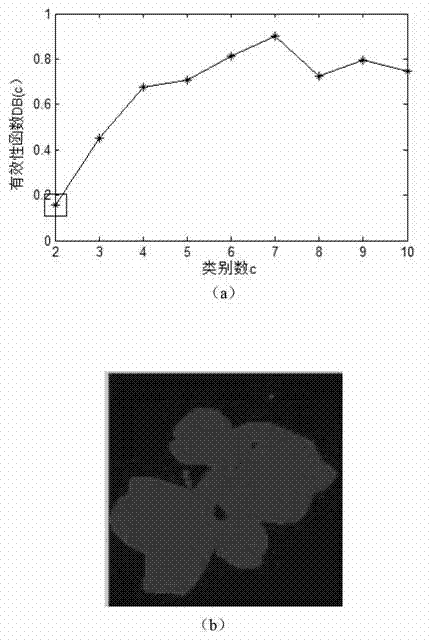

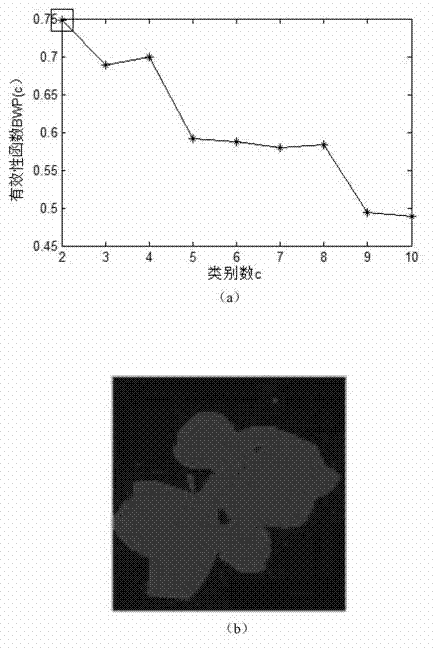

Self-adaptive image segmentation method based on quick global K-means

ActiveCN102903118AReduce space complexityReduce time complexityImage analysisPattern recognitionComputation complexity

The invention discloses a self-adaptive image segmentation method based on a quick global K-means, mainly solving the problems of poor effect and high calculation complexity of self-adaptively segmented images in the prior art. The self-adaptive image segmentation method is implemented through the following steps of: (1) reading an image to be segmented, and extracting texture characteristics of the image to be segmented; (2) setting a search range of an image cluster number c; (3) clustering the texture characteristics into c classes by using an improved quick global K-means method so as to obtain a clustering center; (4) calculating the membership grade of each texture characteristic belonging to each class; (5) calculating effectiveness indexes of L(c), L(c-1) and L(c-2) respectively corresponding to cluster number of c, c-1 and c-2 according to the membership grades and the clustering center; and (6) outputting a segmentation result if L(c-1) is more than L(c-2) and L(c-1) is more than L(c), otherwise, assuming c=c+1, and returning to the step (3). Compared with the other methods, the self-adaptive image segmentation method disclosed by the invention has the advantages of low calculation complexity, more accuracy of self-adaptively obtained optimal class number and segmentation result and capability of being used for segmenting and clustering images.

Owner:XIDIAN UNIV

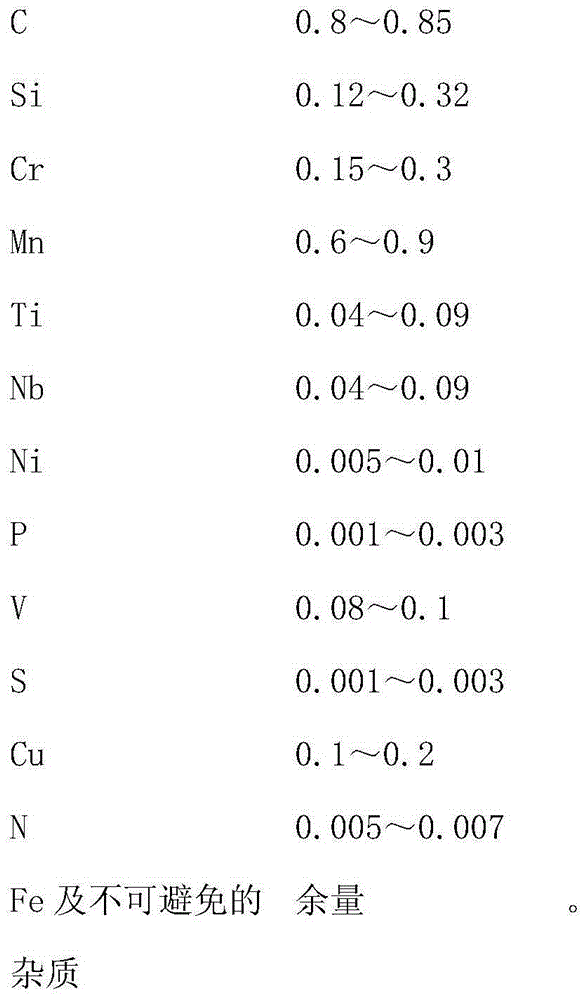

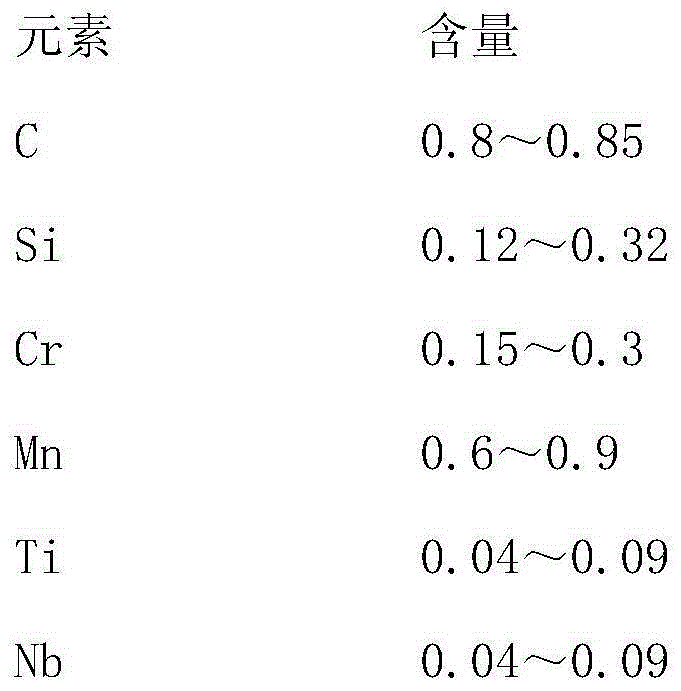

High-temperature-resistant microalloy high-carbon steel 82B wire rod and preparation method thereof

The invention relates to a high-temperature-resistant microalloy high-carbon steel 82B wire rod. Raw materials comprise carbon, silicon, chromium, manganese, titanium, niobium, nickel, phosphorus, vanadium, sulfur, copper, nitrogen and iron. The content of the carbon is matched with the content of the chromium, so that the strength of the wire rod is improved, and mechanical properties are met. The vanadium and the nitrogen are used cooperatively, so that the strength of the wire rod is further improved, and the plasticity and the fatigue performance are improved. The carbon, the chromium, the vanadium and the nitrogen are matched with the other components, and specially designed technological parameters are adopted in the processes of smelting with a converter, secondary refining, square billet continuous casting and square billet rolling, so that the average carbon segregation is smaller than 1.03, internal cracks reach the level 0 to the level 2, and the sorbite content is not smaller than the index of 93%; A-class, B-class, C-class, D-class and DS-class non-metallic inclusions are all smaller than 1.5, the tensile strength is 1150-1250 MPa, and the section shrinkage rate is larger than 30%; especially a steel strand made of the wire rod has the characteristics of being low in slack property, and high in yield ratio and ductility.

Owner:天津市新天钢中兴盛达有限公司

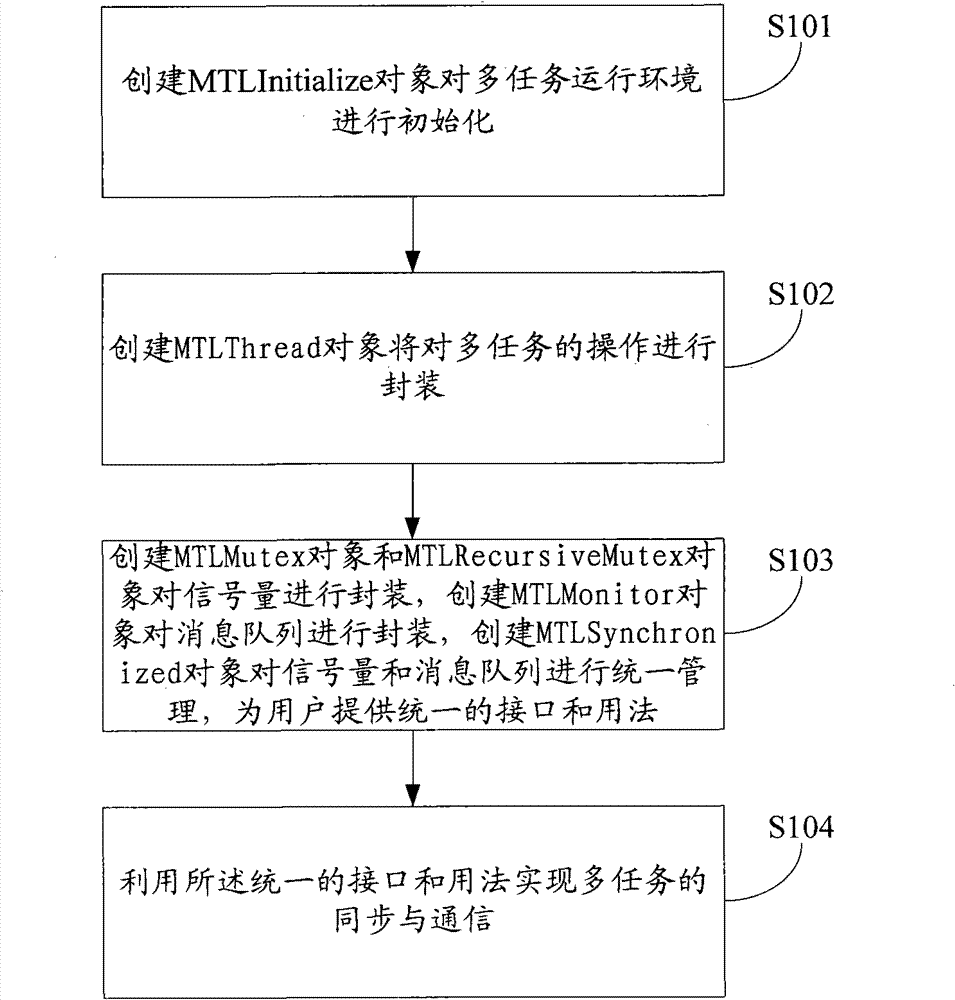

VxWorks multitask synchronization and communication method

ActiveCN101872317BReduce difficultyProgram synchronisationInterprogram communicationMessage queueData synchronization

The invention discloses a VxWorks multitask synchronization and communication method which comprises the following steps of: creating an MTLInitialize object to initialize a multitask operation environment; creating an MTLThread object to package the multitask operation; creating an MTLMutex object and an MTLRecursiveMutex object to package the semaphore, creating an MTLMonitor object to package a message queue, creating an MTLSynchronized object to carry out centralized management on the semaphore and the message queue, and providing uniform interface and usage for users; and realizing the multitask synchronization and communication by utilizing the united interface and usage. The invention realizes the synchronization and the communication among a plurality of tasks freely by carrying out the packaging on the message queue and the semaphore of VxWorks by utilizing a C++ class packaging method, thereby greatly reducing the multitask cooperation difficulty.

Owner:山东中创软件商用中间件股份有限公司

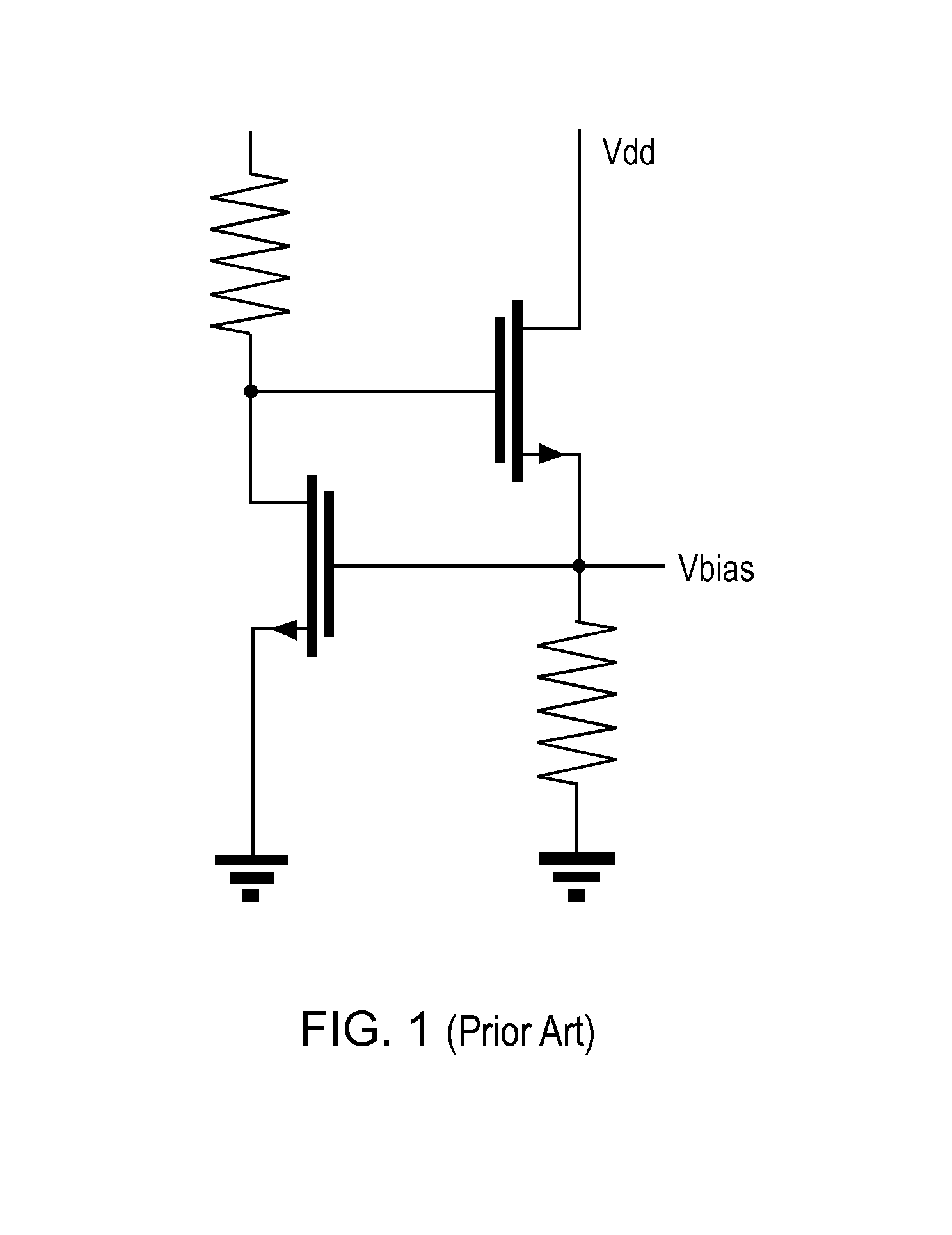

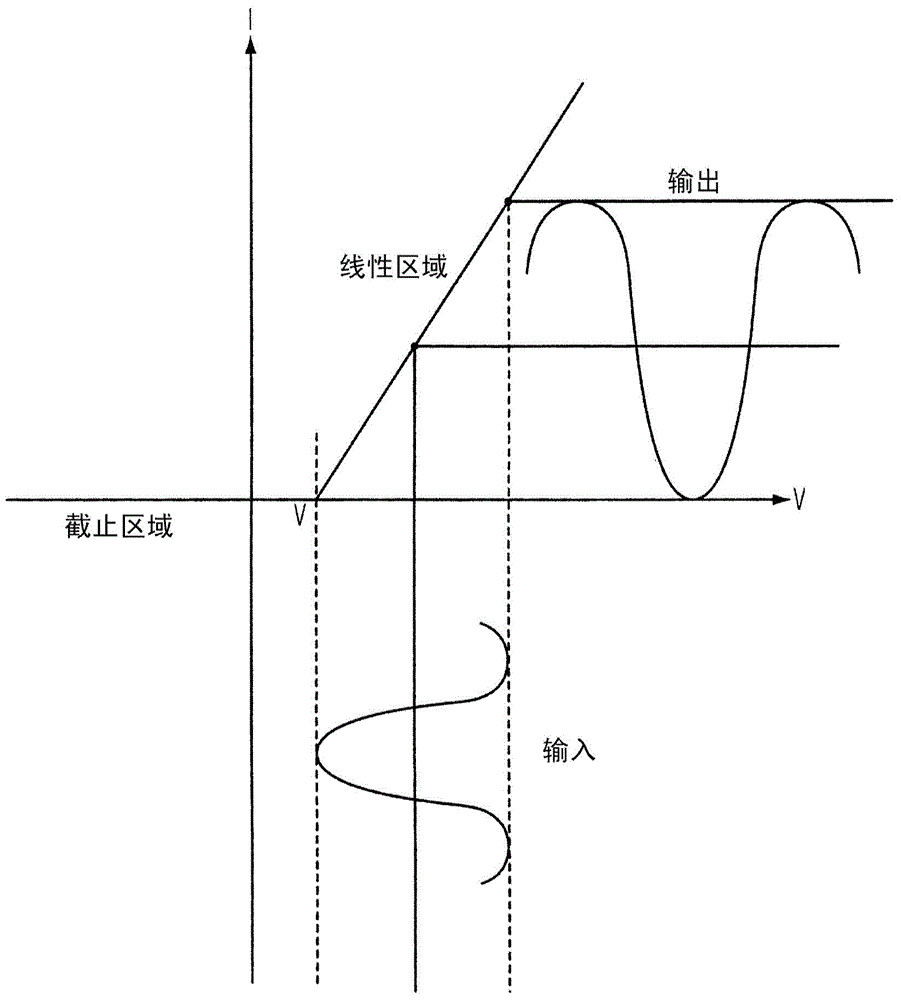

Bias circuit

ActiveUS20140210557A1Lower impedanceControl generationHigh frequency amplifiersSemiconductor/solid-state device detailsAudio power amplifierEngineering

Proposed is a bias circuit for a transistor in a C class amplifier. The bias circuit comprises: a class AB amplifier bias voltage generating means adapted to generate a bias voltage at an output terminal; and a transistor connected between the output terminal and a first reference voltage, the control terminal of the transistor being connected to a second reference voltage via a switch. Closure of the switch connects the second reference voltage to the control terminal of the transistor to cause a shift in the bias voltage generated by the class AB amplifier bias voltage generating means to achieve a predetermined class C bias voltage at the output terminal.

Owner:AMPLEON NETHERLANDS

System and method for reducing the static footprint of mixed-language JAVA classes

InactiveUS8756616B2Minimizing functionality-gapSmall footprintInterprogram communicationCode compilationProgramming languageJava classes

A system and a method for minimizing the functionality-gap between JAVA™ and native platforms while keeping the impact on each JAVA™ API static footprint as small as possible. A JAVA™ Runtime Dynamic Invocation API is used for low-level bridging between JAVA™ and C / C++, enabling the dynamic invocation of native C / C++ functions and C++ class / object methods from the JAVA™ side without adding any additional ad hoc implemented native code to the overall JAVA™ component implementation. Thereby, the need to write new native code when implementing a JAVA™ component that needs to invoke some native functionality is reduced.

Owner:CORE WIRELESS LICENSING R L

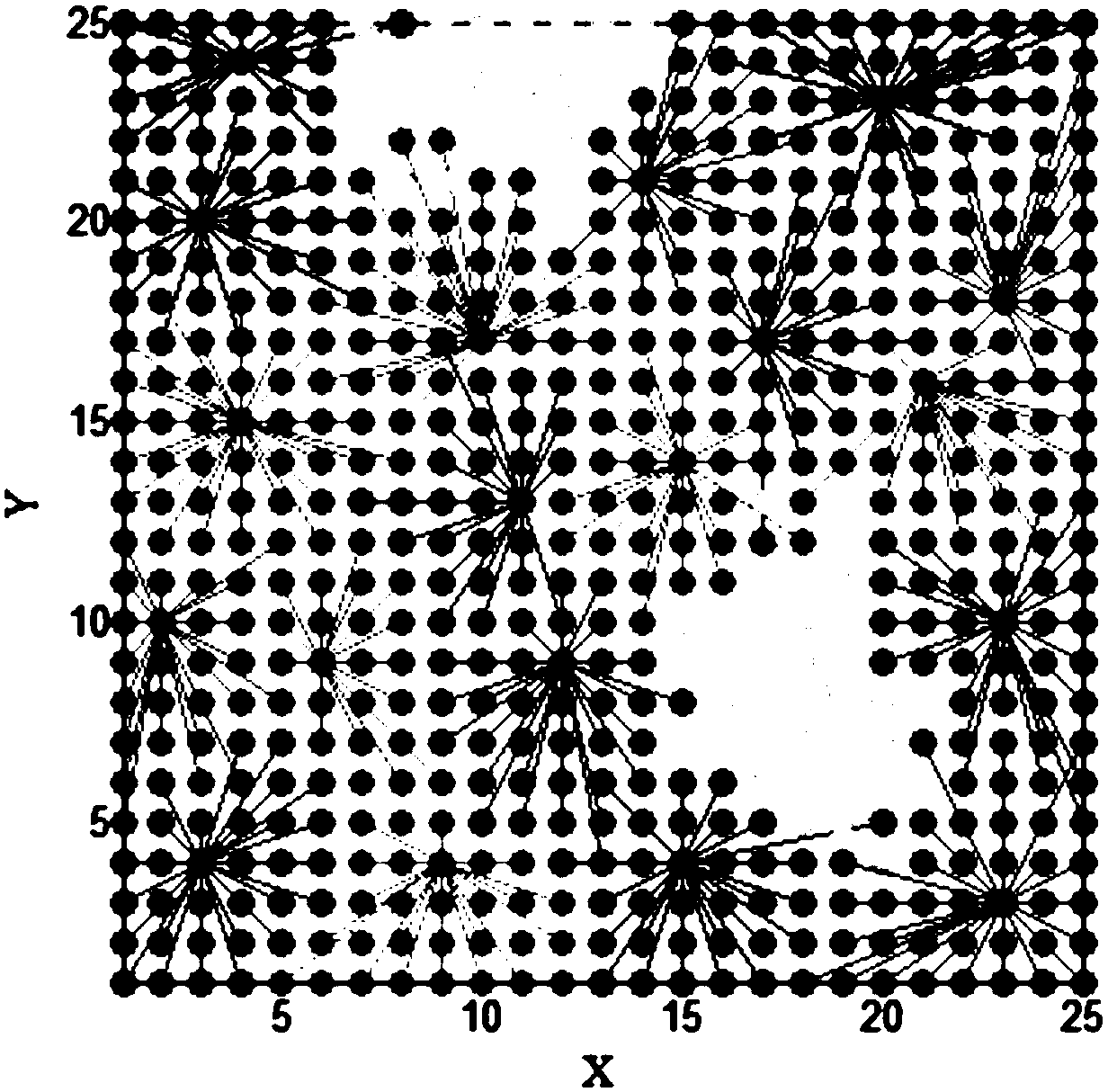

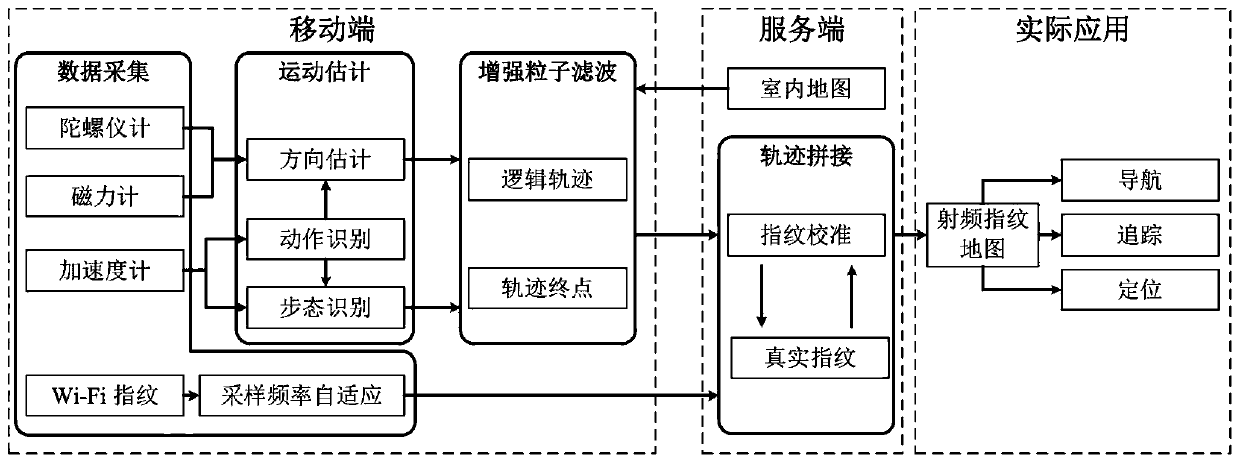

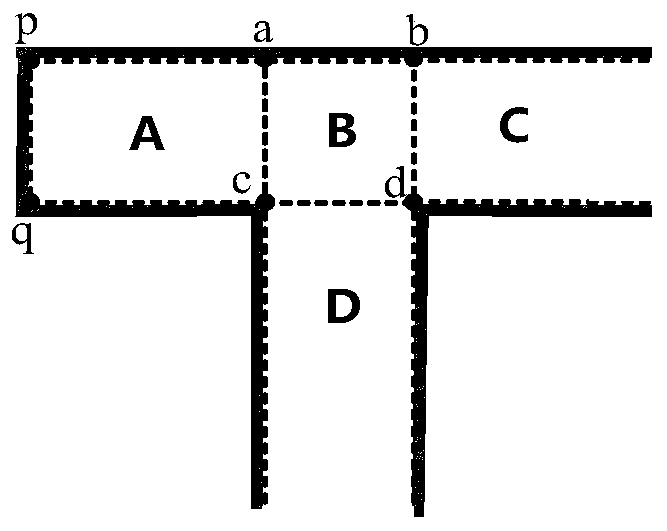

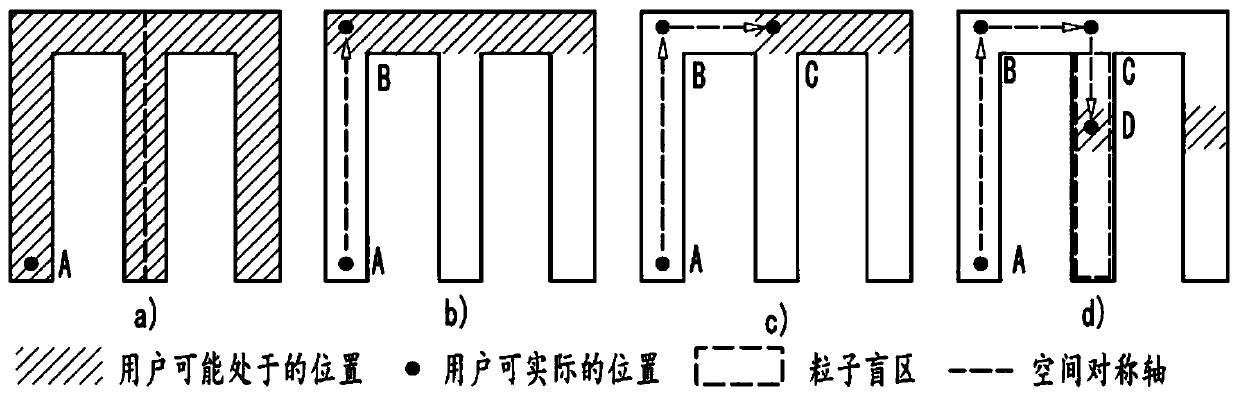

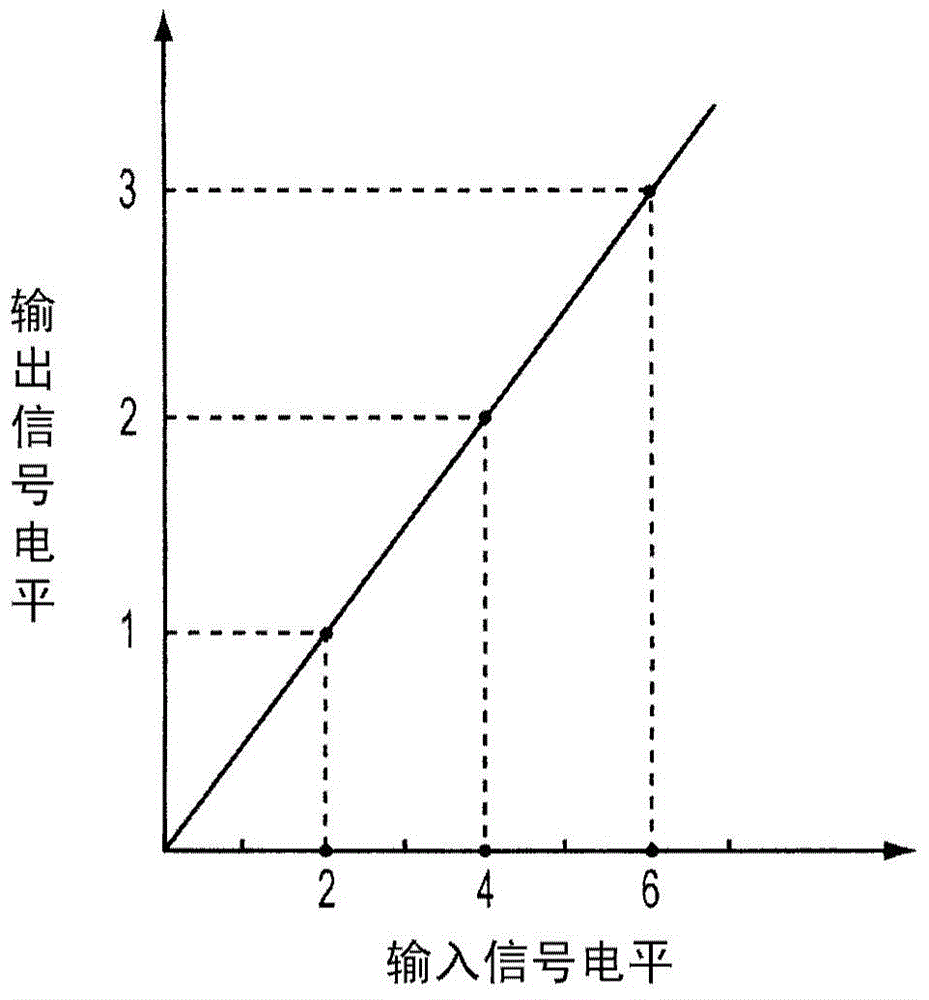

Method for eliminating ambiguity of wireless fingerprint map

ActiveCN110351666AImprove fingerprint accuracyImprove efficiencyCharacter and pattern recognitionTransmission monitoringAlgorithmAmbiguity

The invention discloses a method for eliminating ambiguity of a wireless fingerprint map, which relates to the technical field of positioning services and comprises the following steps: S1, determining the lowest sampling period of a mobile terminal, and acquiring inertial sensor data and RSSI data of the mobile terminal; S2, converting the inertial sensor data into a logic track and an end pointset of the logic track through particle filtering; S3, dividing the end point set into A, B and C classes according to the weight, and correspondingly forming A, B and C class track clusters; S4, forming queues by the obtained A, B and C class track clusters; S5, eliminating fingerprint ambiguity. The indoor wireless fingerprint map generating method has the advantages that trajectory ambiguity iseliminated through trajectory joint constraint, the trajectory utilization rate is increased, a large number of short trajectories are utilized, the use efficiency of data is improved in the mode ofincreasing the trajectory utilization rate, and the defect of the total data amount caused by low-frequency sampling is overcome.

Owner:河北知微科技有限公司

Mixed-class amplifier

ActiveCN104953965AHigh frequency amplifiersAmplifier modifications to raise efficiencyAudio power amplifierHarmonic

The invention provides a power amplifier (10). The power amplifier (10) is allocated to be used for generating impedance at the harmonic frequency, so that the power amplifier (10) is operated in a C-class mode within the low output amplitude range, and is operated in an F-class or inverted F-class mode within the high output amplitude range.

Owner:TELEFON AB LM ERICSSON (PUBL)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com