Thermoplastic low-smoke halogen-free high-flame-retardant polyolefin sheath material and preparation method thereof

A polyolefin sheath, thermoplastic technology, used in plastic/resin/wax insulators, organic insulators, conductors, etc., can solve problems such as difficulty and many combustibles, achieve easy operation, good compatibility, and ensure long-term service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

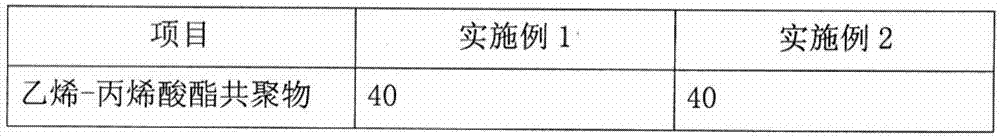

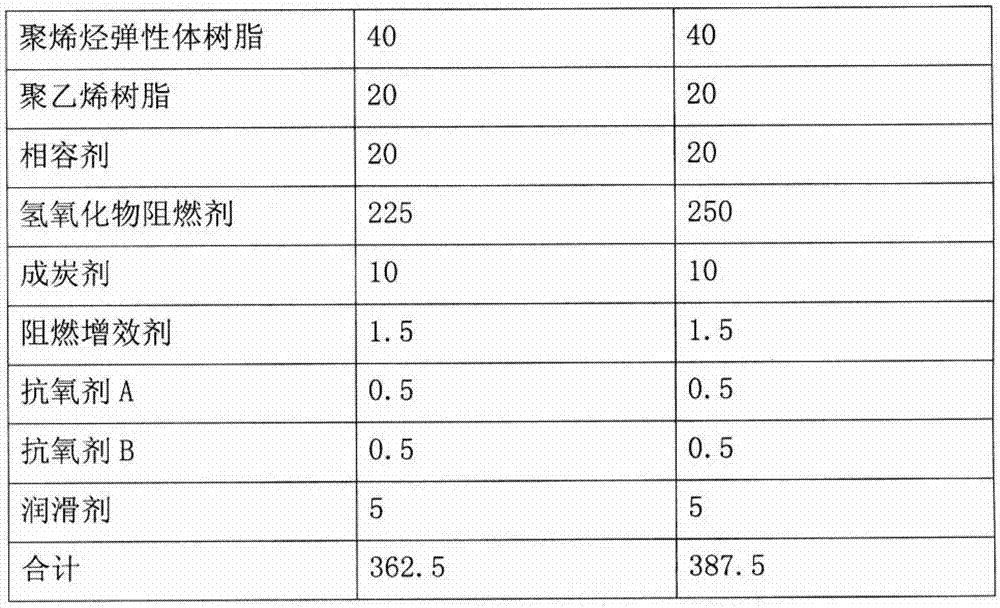

Embodiment 1

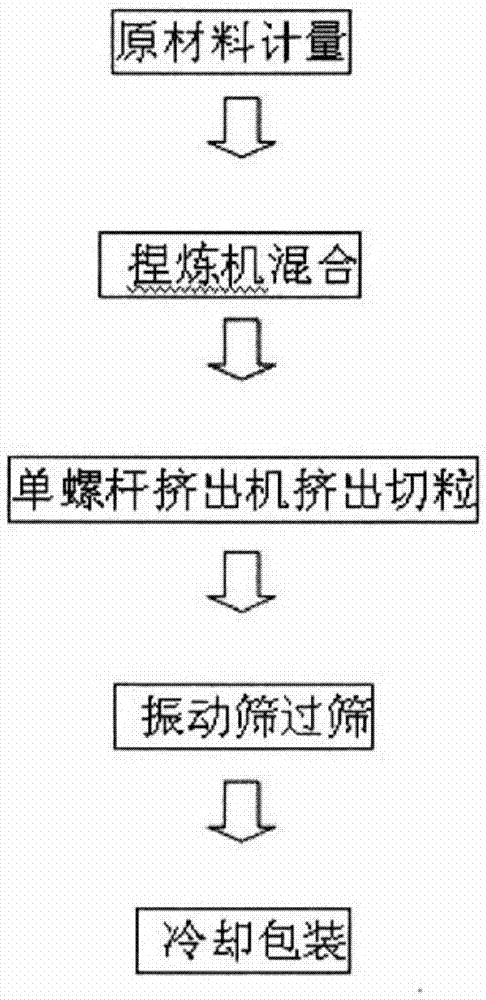

[0020] The preparation of embodiment 1:

[0021] Prepare the raw material formula according to the weight parts shown in Table 1, put it into the kneader and mix it evenly, control the mixing temperature at 140°C, and then send it into a single-screw extruder with a diameter of 120mm to extrude and pelletize, and the extrusion temperature is controlled At 110 to 150°C, the extrusion speed is controlled at 300 rpm, then sieved through a vibrating sieve, and finally cooled to below 50°C for packaging to complete the preparation of the finished product.

Embodiment 2

[0022] The preparation of embodiment 2:

[0023] Prepare the raw material formula according to the weight parts shown in Table 1, put it into the kneader and mix it evenly, control the mixing temperature at 150°C, and then send it into a single-screw extruder with a diameter of 120mm to extrude and pelletize, and the extrusion temperature is controlled At 110 to 150°C, the extrusion speed is controlled at 200 rpm, then sieved through a vibrating sieve, and finally cooled to below 50°C for packaging to complete the preparation of the finished product.

[0024] The main performance requirements of the thermoplastic low-smoke, halogen-free and highly flame-retardant polyolefin sheath material prepared in the embodiment of the present invention are shown in Table 2:

[0025] Table 2 shows the performance requirements of the thermoplastic low-smoke, halogen-free and highly flame-retardant polyolefin sheathing material prepared in the examples of the present invention

[0026] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com