Ammonium phosphate high-effect superfine dry powder extinguishing agent and production method thereof

A technology of ultra-fine dry powder and production method, which is applied in the direction of fire prevention equipment, etc. It can solve the problems that it is difficult to achieve rapid and uniform mixing of gas and powder, the inability to maintain a loose powder state for a long time, and poor powder movement performance, etc., to achieve excellent submersion Type fire extinguishing efficiency, excellent smoke suppression function, good effect of synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

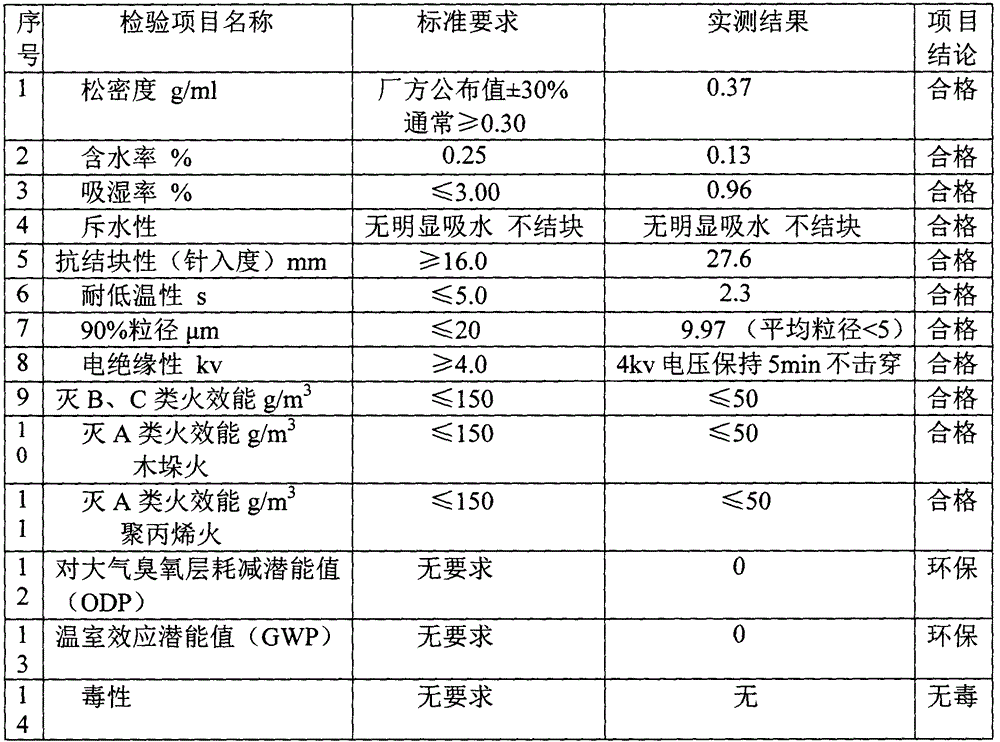

[0030] An ammonium phosphate high-efficiency superfine dry powder fire extinguishing agent and a production method thereof.

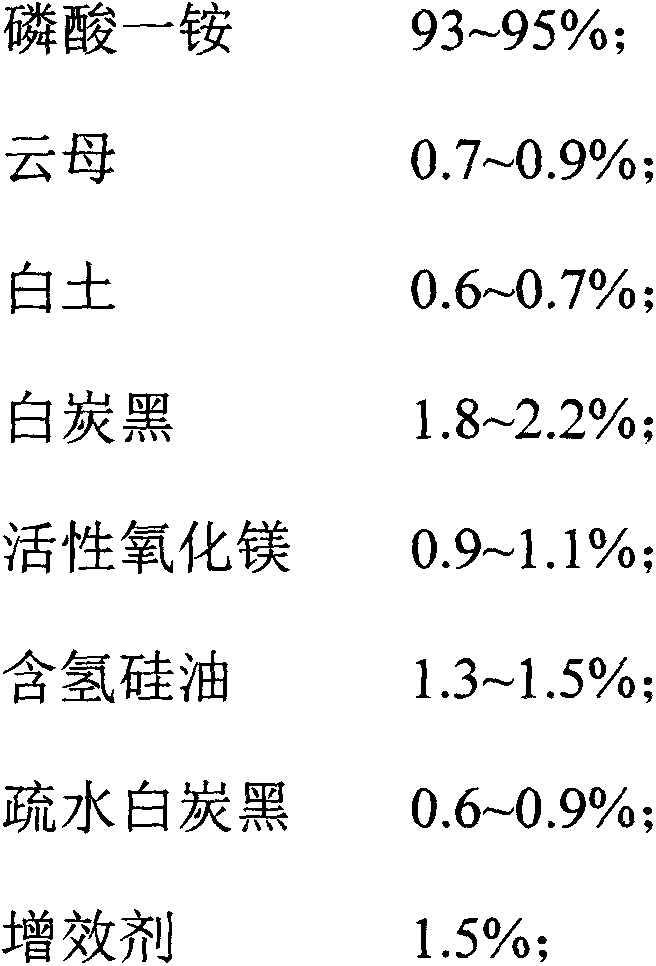

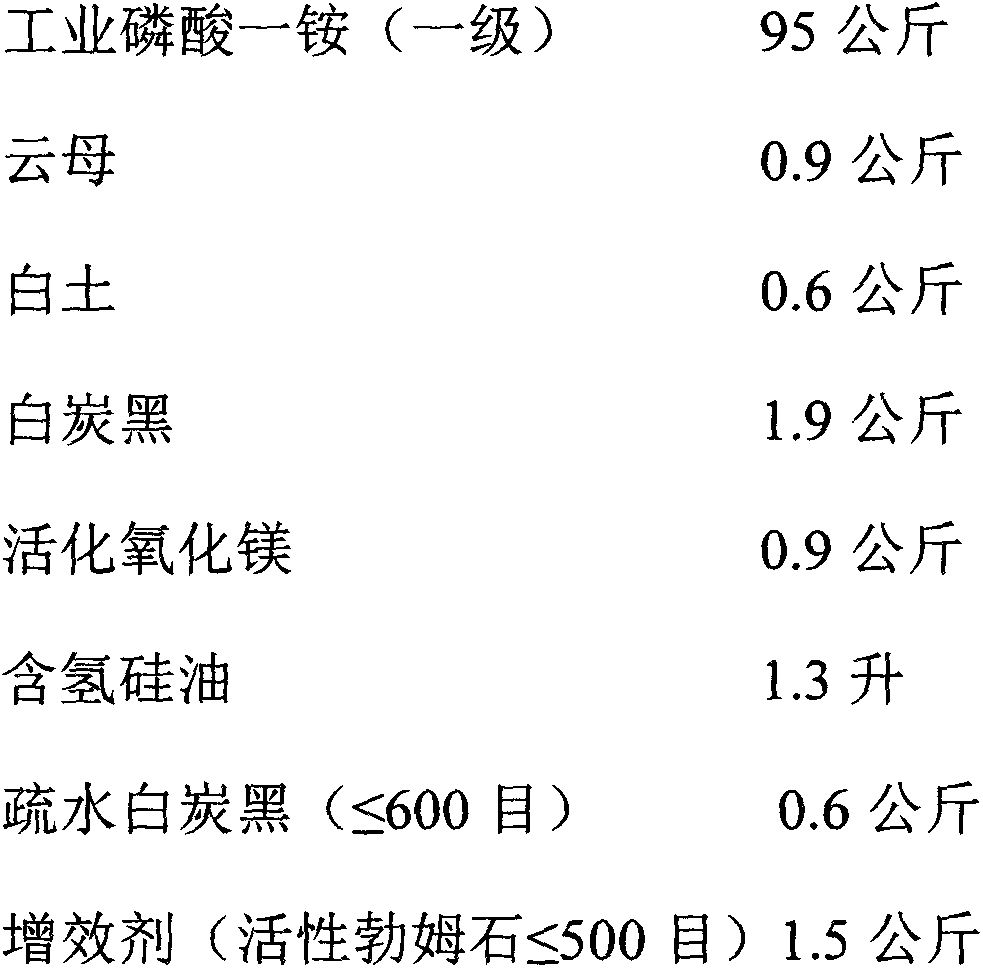

[0031] 1. Composed of the following components by weight (based on 100 kg):

[0032]

[0033] 2. Production process:

[0034] (1) monoammonium phosphate passes through 80 mesh sieves through Renault mill coarse powder;

[0035] (2) Put the monoammonium phosphate of the coarse powder together with mica, white clay, white carbon black and additives into the ultrafine pulverizer and pulverize until the average particle size is ≤5 μm;

[0036] (3) The above-mentioned fine powder material is silicified using silicone oil in a coating machine:

[0037] a. After the fine powder material is added to the coating machine, the temperature rises to 60°C and sprays silicone oil at a speed of 150r / min;

[0038] b. Add hydrophobic white carbon black 15 minutes after spraying silicone oil;

[0039] c. Continue silicification for 15 minutes and raise the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com