Device for recovering photoresist in coating machine pipeline

A technology for recycling pipelines and photoresists, which is applied in the fields of photosensitive material processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of photoresist waste in pipelines, achieve enhanced competitiveness, easy operation, and save manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

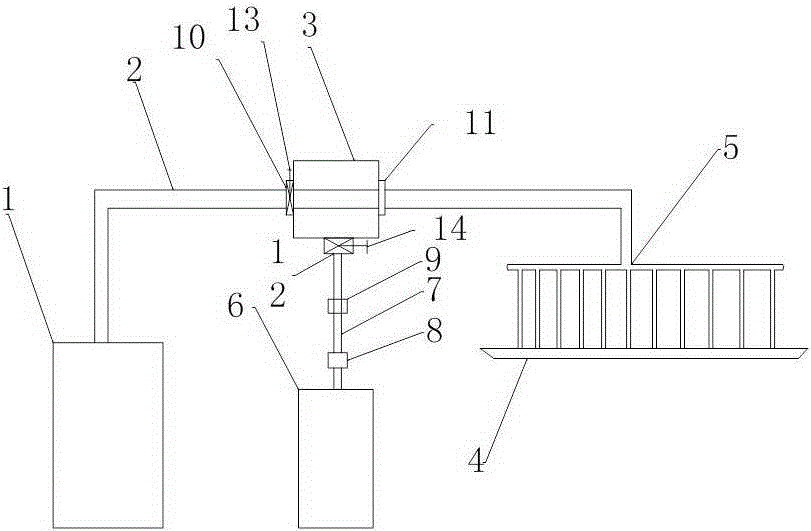

[0018] like figure 1 As shown, a device for reclaiming photoresist in the coating machine pipeline, including photoresist container, photoresist pipeline, photoresist extraction device, coating scraper, and coating machine pipeline, also includes photolithography The photoresist recovery container is connected with the photoresist extraction device through the photoresist recovery pipeline, the photoresist recovery pipeline is provided with a filter and a flow meter, and the photoresist extraction device is provided with three ports, the first port is connected with the photoresist pipeline, the second port is connected with the coater pipeline, and the third port is connected with the photoresist recovery pipeline, and the first port and the third port of the photoresist extraction device are respectively A first gate valve and a second gate valve are provided, and the way of extracting the photoresist by the photoresist extraction device is a two-way extraction type.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com