Steam condensation system for a granulation installation

A granulation equipment, steam condensation technology, used in lighting and heating equipment, cooling devices, processing discharged materials, etc., to reduce environmental impact, increase operational safety, and save capital and operating expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

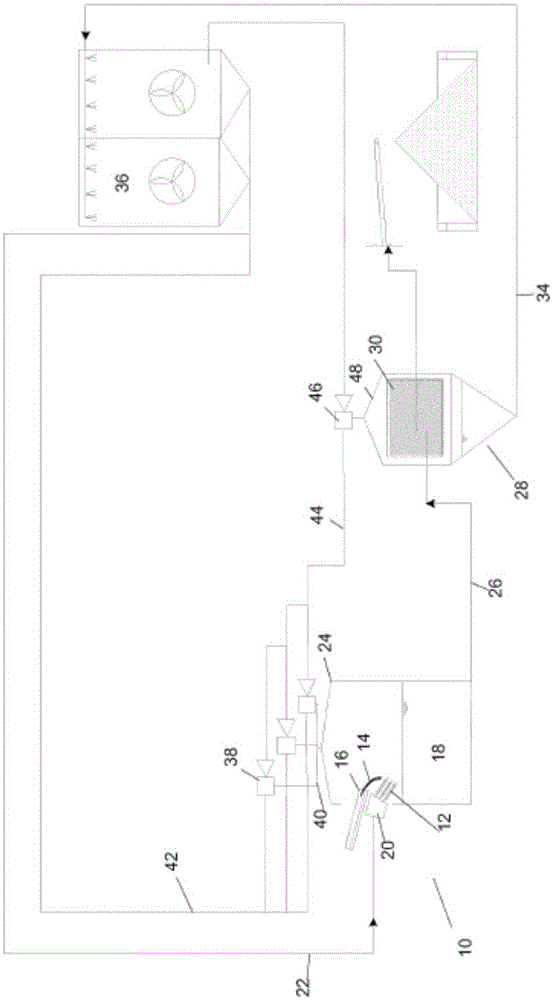

[0042] To illustrate an embodiment of the invention, figure 1 A schematic diagram of a granulation plant 10 designed for slag granulation in a blast furnace plant (which is not shown) is shown. In general, the apparatus 10 is thus used to granulate a stream of molten blast furnace slag by quenching it with one or more jets 12 of relatively cool granulation water. Such as figure 1 As shown, molten slag stream 14 , which inevitably flows out of the blast furnace together with pig iron, falls from hot melt launder end 16 into granulation tank 18 . During operation, a jet of granulated water 12 impinges on molten slag 14 falling from the end 16 of the hot runner, the jet of granulated water being pumped by one or more parallel high pressure pumps (not shown) via A water injection device 20 (also commonly referred to as a "spray box") is supplied by a supply pipe 22 . A suitable configuration of the water injection device 20 is eg described in patent application WO2004 / 048617. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com