Dust purification system

A technology of dust purification and dust box, which is applied in the direction of chemical instruments and methods, combined devices, and separation of dispersed particles, which can solve the problems of affecting the health of operators, the treatment effect is not obvious, and it is easy to cause occupational diseases, so as to achieve the effect of dust treatment Good, compact structure, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

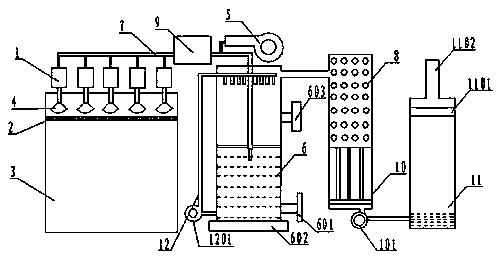

[0017] see figure 1 , the embodiment of the present invention includes:

[0018] The above-mentioned dust purification system includes: a work room, a horizontal filter plate is set on the upper end of the work room, and a filter port is set on the filter plate, which can allow large dust and impurity particles to pass through. A dust box is set above the filter plate. The dust box is in the form of a rectangular parallelepiped. The dust box is connected to the work room through a pipe, and a suction port device is set at the lower end of the dust box. , the upper end of the dust box is connected to the dust removal bag through the exhaust gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com