Tower welding protection device

A protection device and tower technology, applied in welding equipment, plasma welding equipment, applications, etc., can solve the problems of increased repair workload, consistent travel speed, poor surface protection, etc., to improve the first pass rate, avoid air holes, good The effect of gas shielding on the back side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

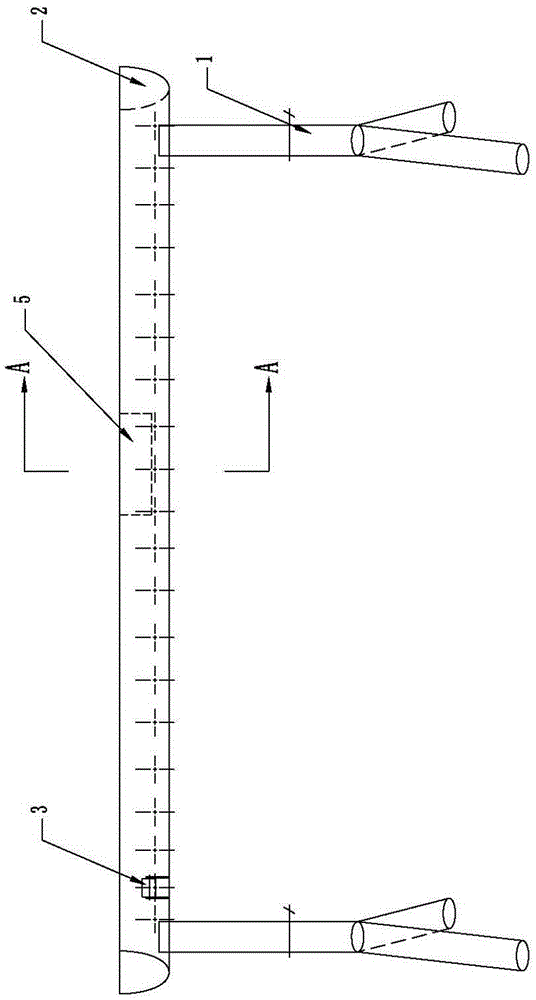

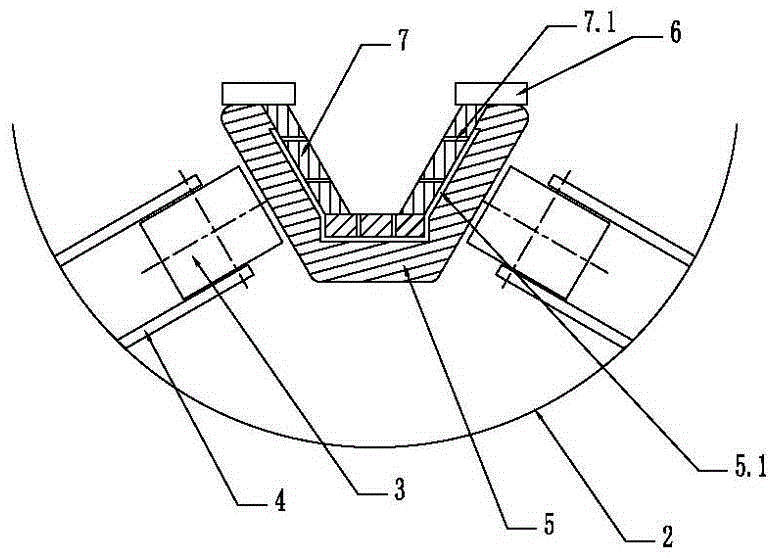

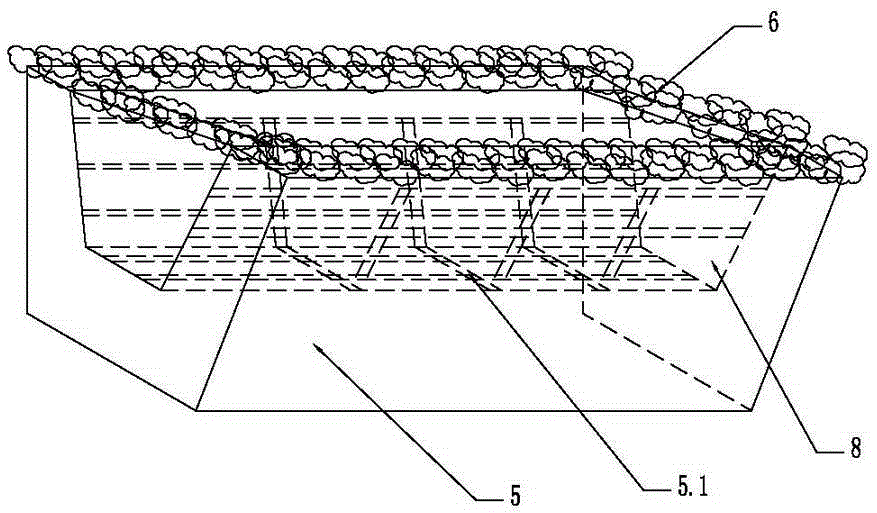

[0013] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a tower welding protection device is characterized in that it includes a bracket 1, an arc-shaped support frame 2, a support wheel 3, a support wheel frame 4, a V-shaped gas shield 5, a high temperature resistant cotton 6, and a copper pad 7 and sealing plate 8; arc-shaped support frame 2 is arranged on the support 1, the arc-shaped concave surface of arc-shaped support frame 2 faces upwards, and several support wheels 3 are arranged in the arc-shaped concave surface of arc-shaped support frame 2 through support wheel frame 4 , the V-shaped gas shield 5 is placed on the supporting wheel 3, the V-shaped concave surface of the V-shaped gas shield 5 faces upwards, a sealing plate 8 is respectively arranged at both ends of the V-shaped gas shield 5, and several copper pads 7 are laid on In the V-shaped concave surface of the V-shaped gas shield 5, a number of ventilation holes 7.1 are provided on the copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com