Welding head for laser welding robot

A laser welding and robot technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult sheet metal, high energy consumption, and low motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

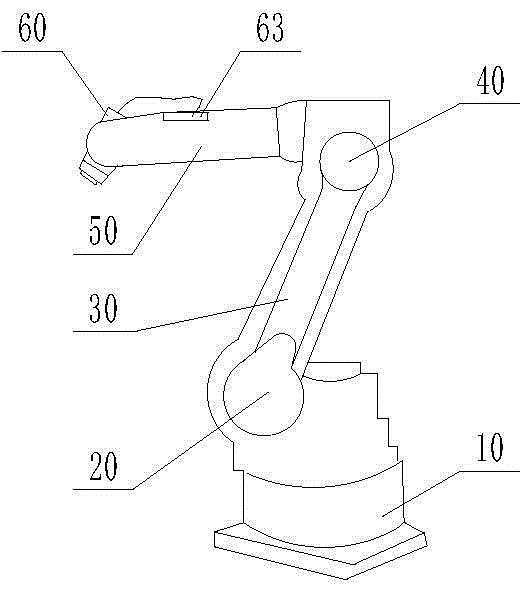

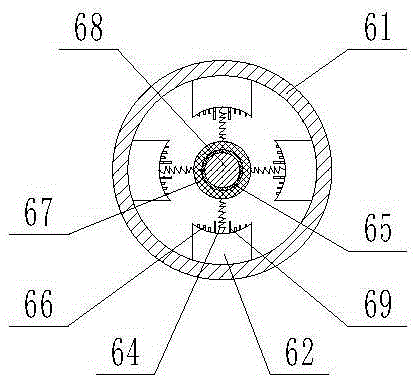

[0016] The reference signs in the drawings of the description include: base 10, main rotating motor 20, main rotating shaft 30, auxiliary rotating motor 40, auxiliary rotating shaft 50, welding head 60, circular swing cylinder 61, electromagnet 62, control board 63 , stage clip 64, rubber expansion sleeve 65, coil coil 66, ring magnet 67, laser nozzle 68, anti-collision column 69.

[0017] The embodiment is basically as attached figure 2 Shown: a welding head for a laser welding robot, including a laser nozzle 68 and a circular swing cylinder 61, the laser nozzle 68 is located in the circular swing cylinder 61, four uniformly distributed on the same circumference of the circular swing cylinder 61 inner wall The electromagnet 62 that is electrically connected with the control board 63 on the auxiliary rotating shaft 50, four electromagnets 62 form an annular cavity, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com