Brewing technology of strawberry wine and strawberry wine prepared through brewing technology

A strawberry wine and strawberry technology, applied in the field of strawberry wine, can solve the problems of poor stability, lack of fullness of wine body, prominent alcohol taste, etc., and achieve the effects of good stability, lower temperature, and mellow wine aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

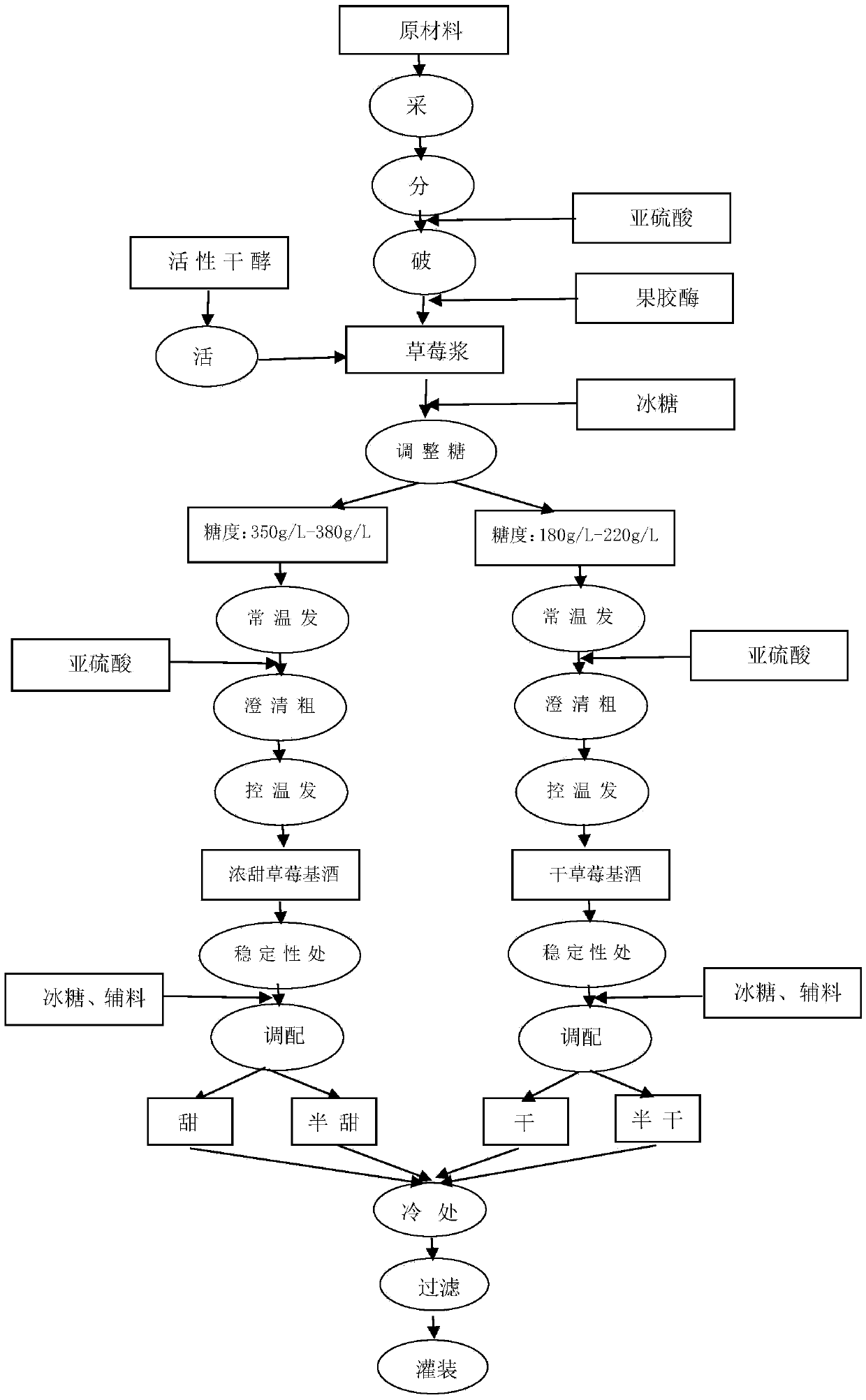

Method used

Image

Examples

Embodiment 1

[0044] Preparation of sweet strawberry wine:

[0045] Fresh strawberries are sorted to remove impurities, washed 2-3 times with clean water, and then added to the beater while adding 50mg / L of sulfurous acid relative to fresh strawberries while crushing, and the crushing outlet is about 1cm. After crushing, add 20mg / L pectinase relative to the fresh strawberries, enzymatically hydrolyze at 20°C for 1.5 hours, add rock sugar to adjust the sugar content of strawberry pulp to 350g / L, and obtain strawberry pulp for later use;

[0046] Dissolve the active dry yeast in warm water equivalent to 10 times its weight and activate it for 20 minutes, then add an equal weight of strawberry pulp to activate it for 20 minutes to obtain activated active dry yeast;

[0047] The activated active dry yeast is inoculated into the strawberry pulp fermenter and fermented to obtain strawberry fermented juice, wherein the amount of yeast added is 0.2g / L (relative to the strawberry pulp); when the alc...

Embodiment 2

[0052] Preparation of sweet strawberry wine:

[0053] Fresh strawberries are sorted to remove impurities, washed 2-3 times with clean water, and then added to the beater while adding 65mg / L of sulfurous acid relative to fresh strawberries while crushing. The crushing outlet is about 1cm. After crushing, add 30mg / L pectinase relative to the fresh strawberries, enzymatically hydrolyze at 24°C for 2.3 hours, add rock sugar to adjust the sugar content of strawberry pulp to 365g / L, and obtain strawberry pulp for later use;

[0054] Dissolve the active dry yeast in warm water equivalent to 10 times its weight and activate it for 20 minutes, then add an equal weight of strawberry pulp to activate it for 20 minutes to obtain activated active dry yeast;

[0055] The activated active dry yeast is inoculated into the strawberry pulp fermenter and fermented to obtain strawberry fermented juice, wherein the amount of yeast added is 0.2g / L (relative to the strawberry pulp); when the alcohol...

Embodiment 3

[0060] Preparation of sweet strawberry wine:

[0061] Fresh strawberries are sorted to remove impurities, washed 2-3 times with clean water, and then added to the beater while adding 80mg / L sulfurous acid relative to fresh strawberries while crushing, and the crushing outlet is about 1cm. After crushing, add 40mg / L pectinase relative to the fresh strawberries and enzymatically hydrolyze at 28°C for 3 hours, add rock sugar to adjust the sugar content of strawberry pulp to 380g / L, and obtain strawberry pulp for later use;

[0062] Dissolve the active dry yeast in warm water equivalent to 10 times its weight and activate it for 20 minutes, then add an equal weight of strawberry pulp to activate it for 20 minutes to obtain activated active dry yeast;

[0063] The activated active dry yeast is inoculated into the strawberry pulp fermenter and fermented to obtain strawberry fermented juice, wherein the amount of yeast added is 0.2g / L (relative to the strawberry pulp); when the alcoh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com