Steel ingot foot and manufacturing method thereof

A steel ingot and ingot foot technology, which is applied in the field of textile devices, can solve the problems of assembly error of steel ingot foot components, high consumption of steel material, and low product precision, and achieve the advantages of not easy to deflection, less steel material consumption, and simple molding process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

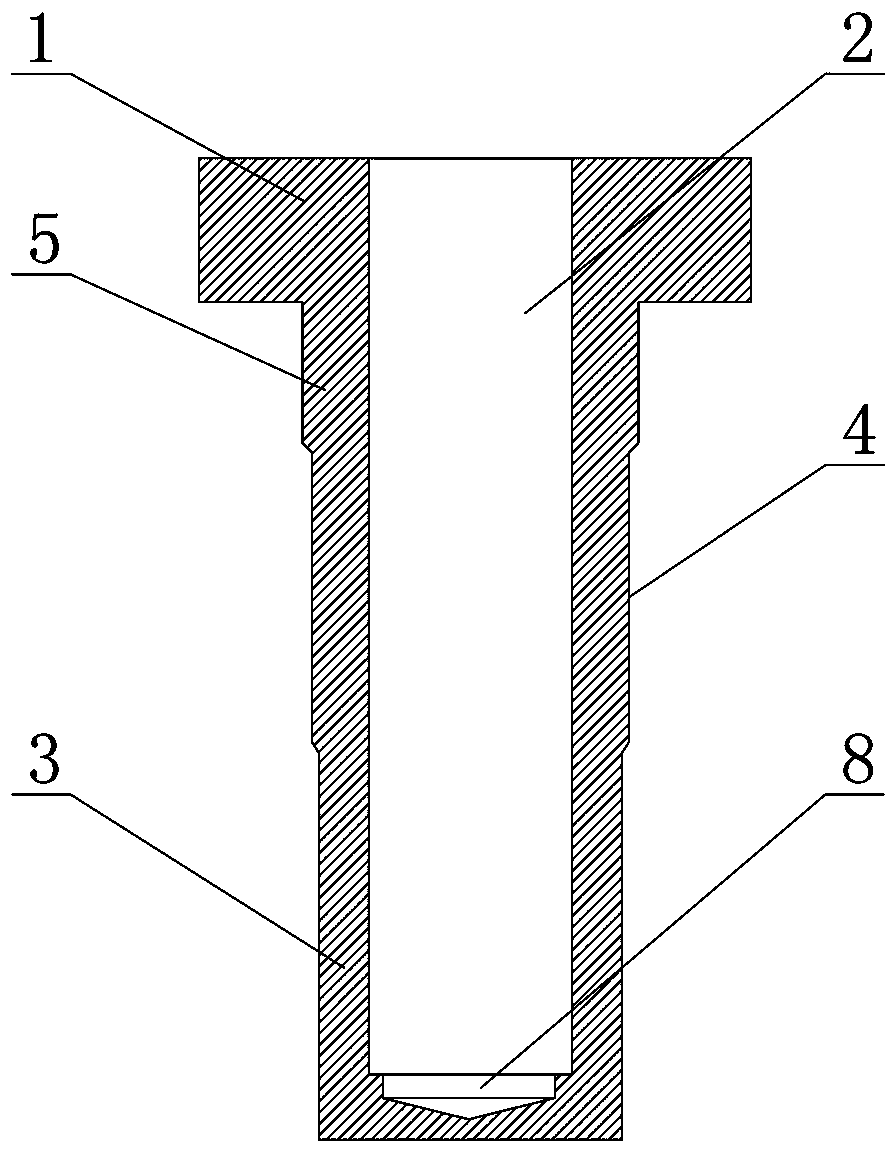

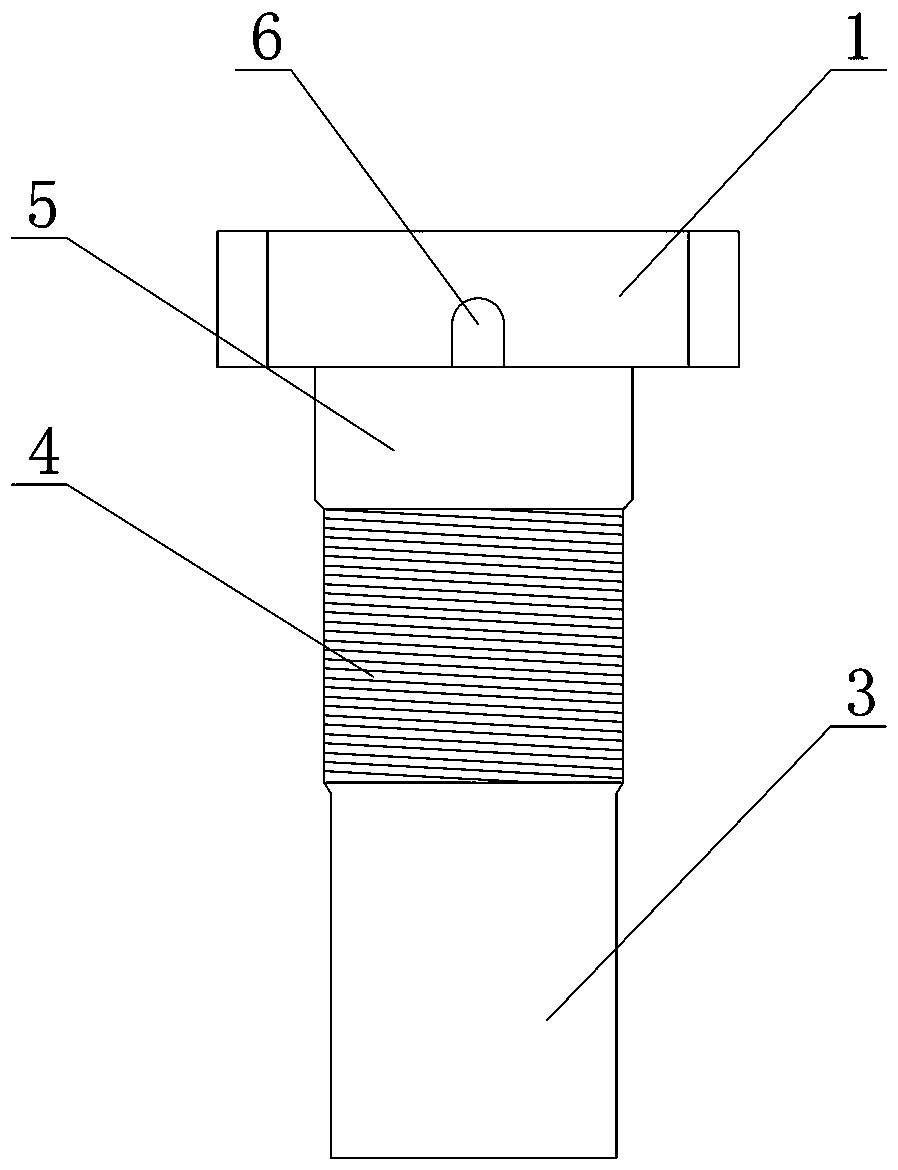

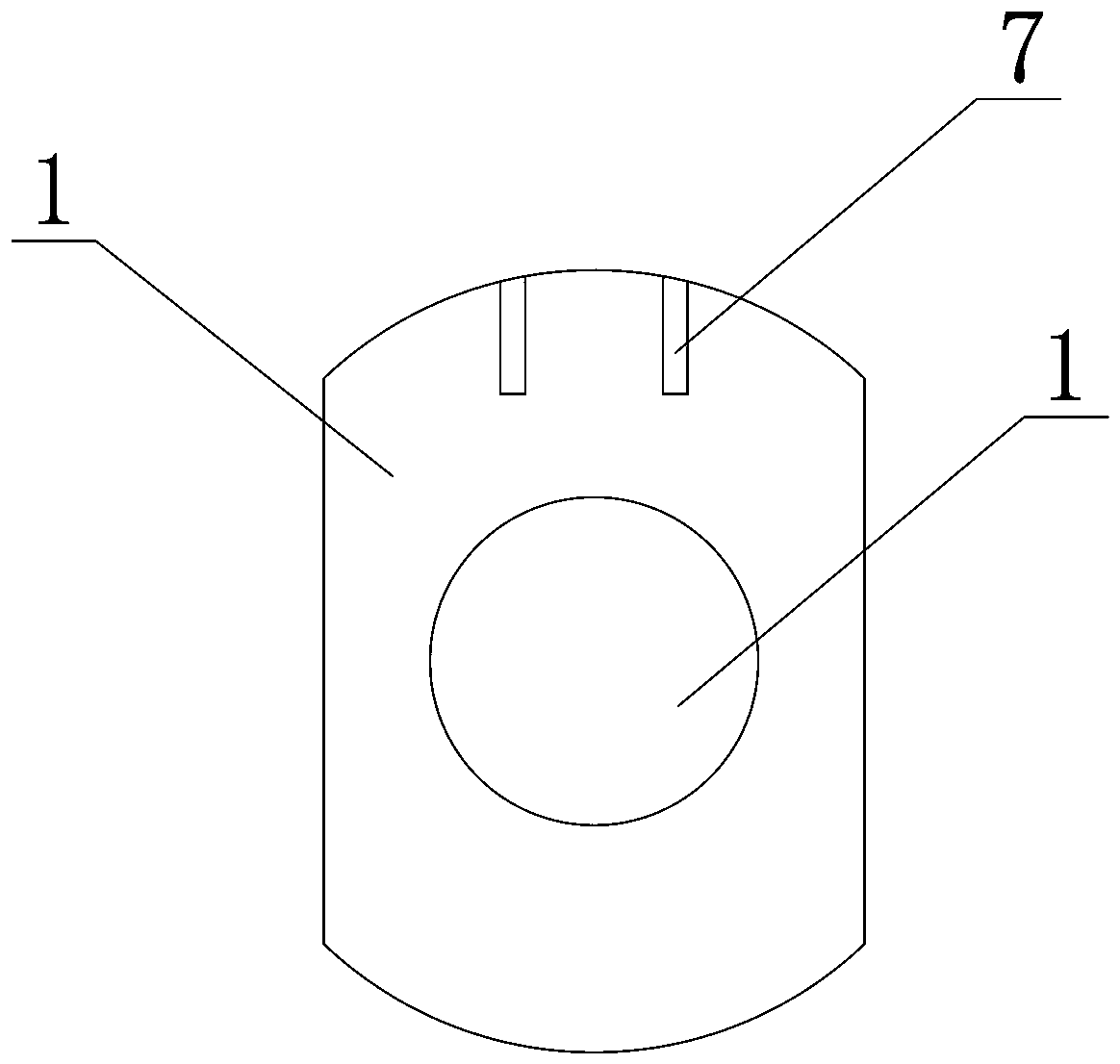

[0041] Such as Figure 1-3 As shown, a steel ingot foot includes a main body formed by integral cold heading and stamping. The blind hole 2 in the spindle foot 3 , wherein the opening of the blind hole 2 is set at the top of the flange 1 , and the bottom end of the blind hole 2 is stamped to form a boss 8 . The outer diameter of the spindle foot 3 decreases stepwise from the top to the bottom, at least one section of the outer wall of the stepped section is provided with threads 4 , and the uppermost section is a vertical positioning section 5 . The opposite two outer ends on the flange 1 are cut into a plane, and a spindle stopper groove 6 is provided on the plane, and the open end of the spindle stopper groove 6 is located at the lower end of the flange 1 . One of the arc ends of the flange 1 is provided with a double-slit ingot hook ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com