Material and method for manufacturing piston

A manufacturing method and technology of pistons, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve problems such as the need to improve the structural strength of pistons, affect the reliability of the whole machine, thermal fatigue damage, etc., and achieve the solution of uneven carbon fiber division and excellent The effect of mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A piston manufacturing material, characterized in that: the piston is made of a carbon fiber reinforced aluminum-based composite material, the surface of the material is coated with 10% carbon fiber T50, and the base layer is made of 90% aluminum alloy ZL109 material. The preparation method is as follows:

[0018] (1) Pretreatment of the carbon fiber T50 surface with SIC isolation layer, disperse the SIC particles in a sol prepared by polycarbosilane and solvent n-hexane to form a suspension, the carbon fiber is ultrasonically coated through the suspension, and the frequency of ultrasonic stirring Controlled at 20KHz, stirring power 4000w, time 40s, and finally dried and dehydrated to obtain carbon fiber T50 coated with SIC isolation layer;

[0019] (2) The aluminum-based ZL109 is smelted in a resistance furnace at 740°C, and the temperature is kept for 10 minutes after all melting.

[0020] (3) The pre-treated carbon fiber is preheated to 600°C, and then directly added to th...

Embodiment 2

[0022] The rest is the same as the first embodiment, the difference is that the surface of the material described in claim 1 is covered with 20% carbon fiber T50, and the base layer is made of 80% aluminum alloy ZL109 material.

Embodiment 3

[0024] The rest is the same as the first embodiment, the difference is that the surface of the material described in claim 1 is covered by 30% carbon fiber T50, and the base layer is made of 70% aluminum alloy ZL109 material.

[0025]

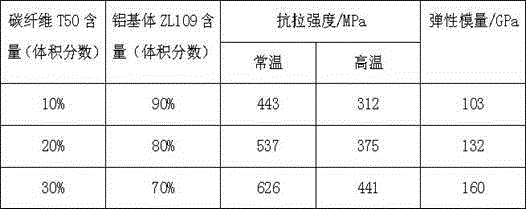

[0026] Through the above three examples, the three sets of data in the above table show that when the carbon fiber T50 content in the material is 30% and the aluminum matrix content is 70%, the carbon fiber composite material has the best mechanical properties and the produced piston has the best performance. It is more conducive to the production of pistons.

[0027] The piston manufactured by the present invention uses a carbon fiber reinforced aluminum-based composite material. Compared with traditional aluminum alloy, cast iron, and cast steel materials, the piston manufactured by this material has lighter weight, low thermal expansion coefficient, good thermal conductivity, and high temperature conditions. More wear-resistant. The method for m...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap