Silent chain transmission device

A technology of transmission device and silent chain, which is applied in the direction of transmission chain, etc., can solve the problems of poor meshing sound between silent chain and sprocket, increased vibration sound of silent chain strings, and poor winding of sprocket, etc., to achieve the suppression of creeping teeth , Reduce the string vibration sound, and stabilize the action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

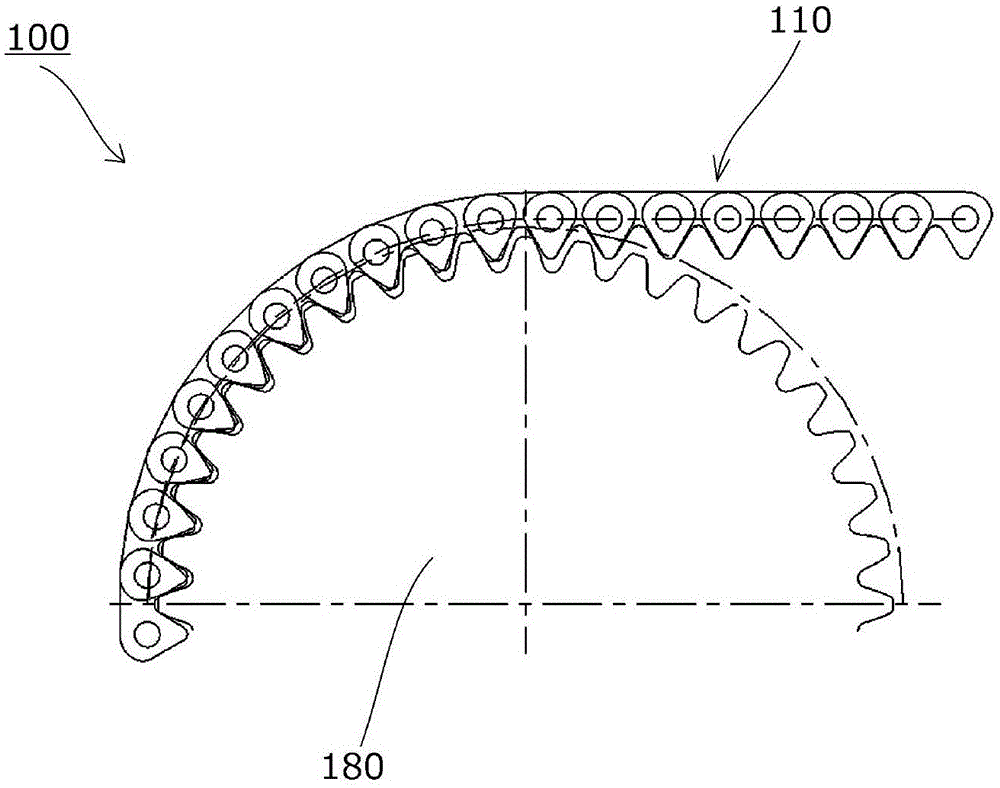

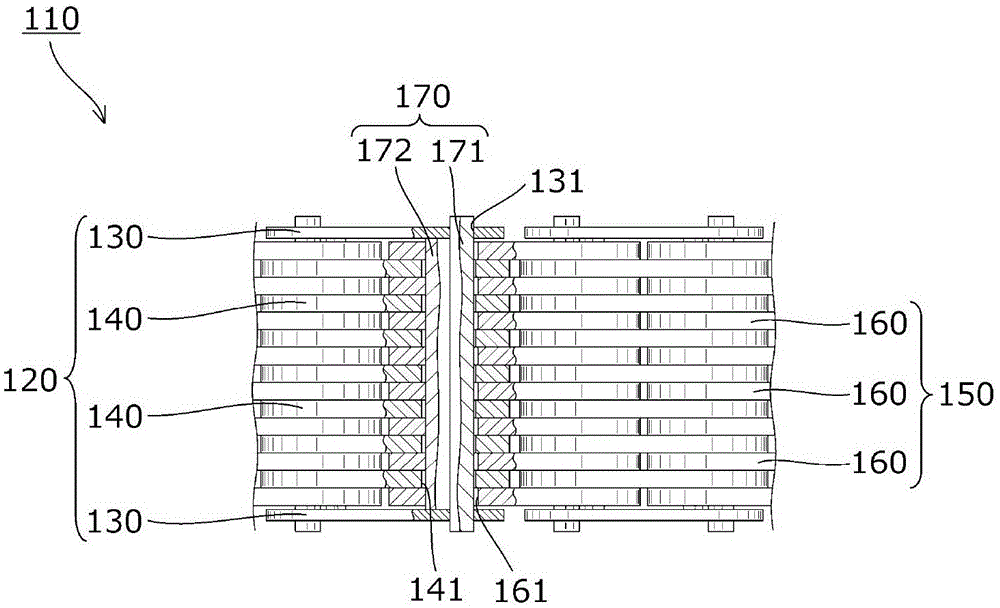

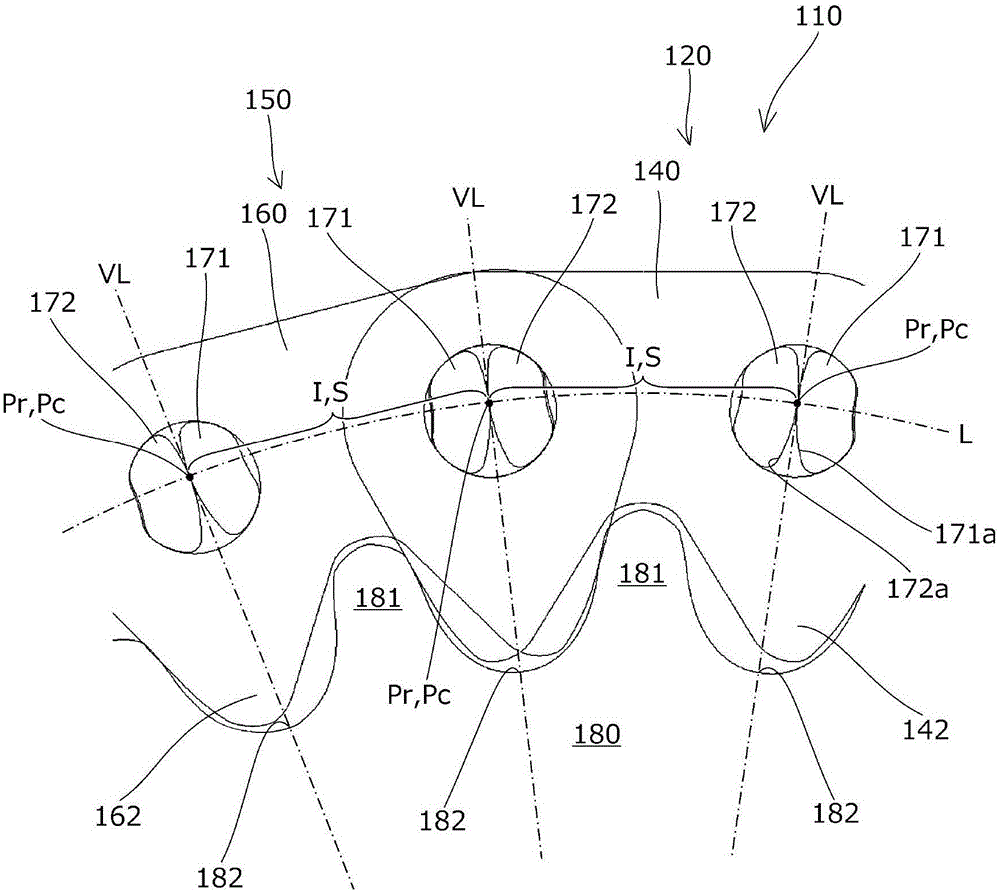

[0034] The present invention is a silent chain transmission device composed of a silent chain and a sprocket wheel. The silent chain is alternately connected by a pair of rotating pins in the length direction of the chain. The guide row constituted by the flat plate and the non-guided row constituted by a plurality of inner flat plates, a pair of rotating pins are formed by long pins and short pins inserted into the front and rear pair of pin holes arranged on the middle flat plate and the inner flat plate. As long as the silent chain is wound around the sprocket with a low load, the pitch between the pivot points of the pivot pins of the front and rear pin holes of the non-guide row is set to be equal to the pitch of the sprocket, as long as the structure is simple , to stabilize the behavior of the chain when the chain moves, to suppress the occurrence of tooth creep, and to reduce the sound of string vibration and meshing, the specific implementation form can be arbitrary. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com