Reinforced polyethylene complex pipeline

A technology of composite pipes and polyethylene, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of consuming manpower and material resources, reducing production efficiency, etc., to improve production efficiency, prolong service life, and use at low cost Effect

Inactive Publication Date: 2016-03-02

HAIXI HUAHUI CHEM MASCH CO LTD

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It is necessary to re-purchase pipes and re-lay pipes, again consuming manpower and material resources, and reducing production efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

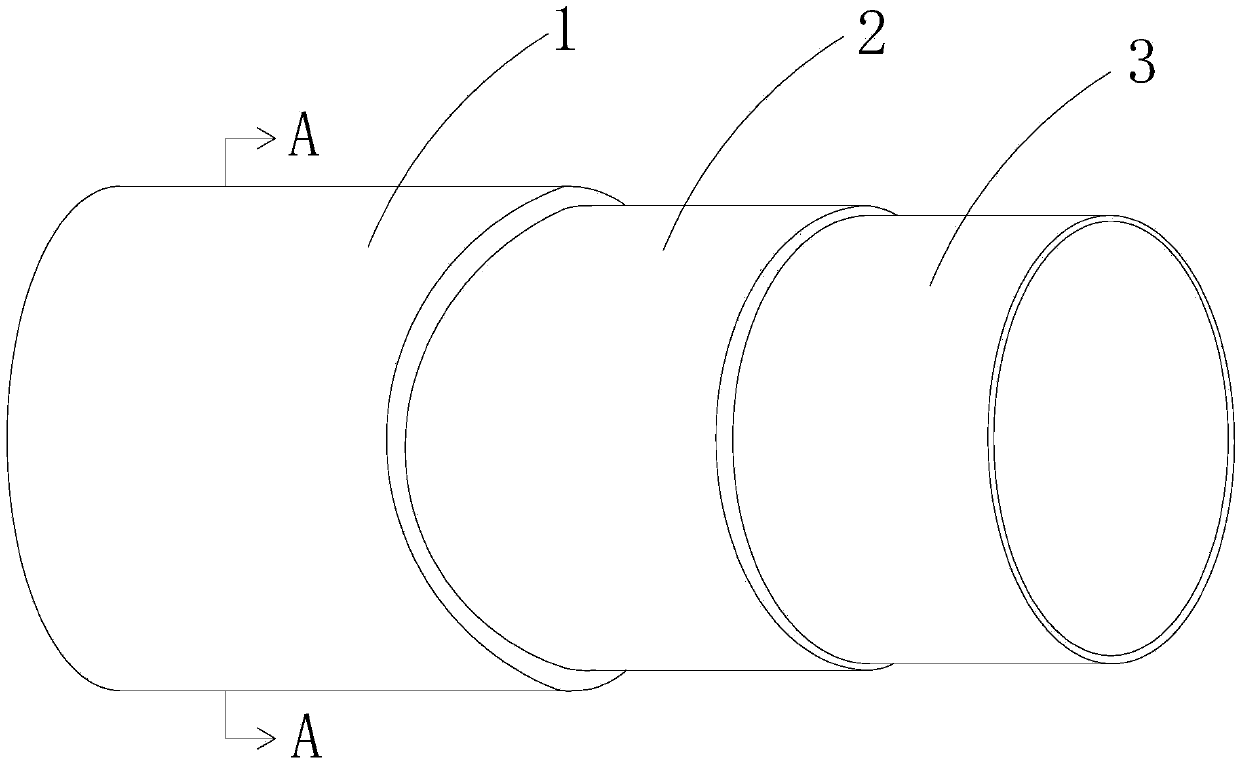

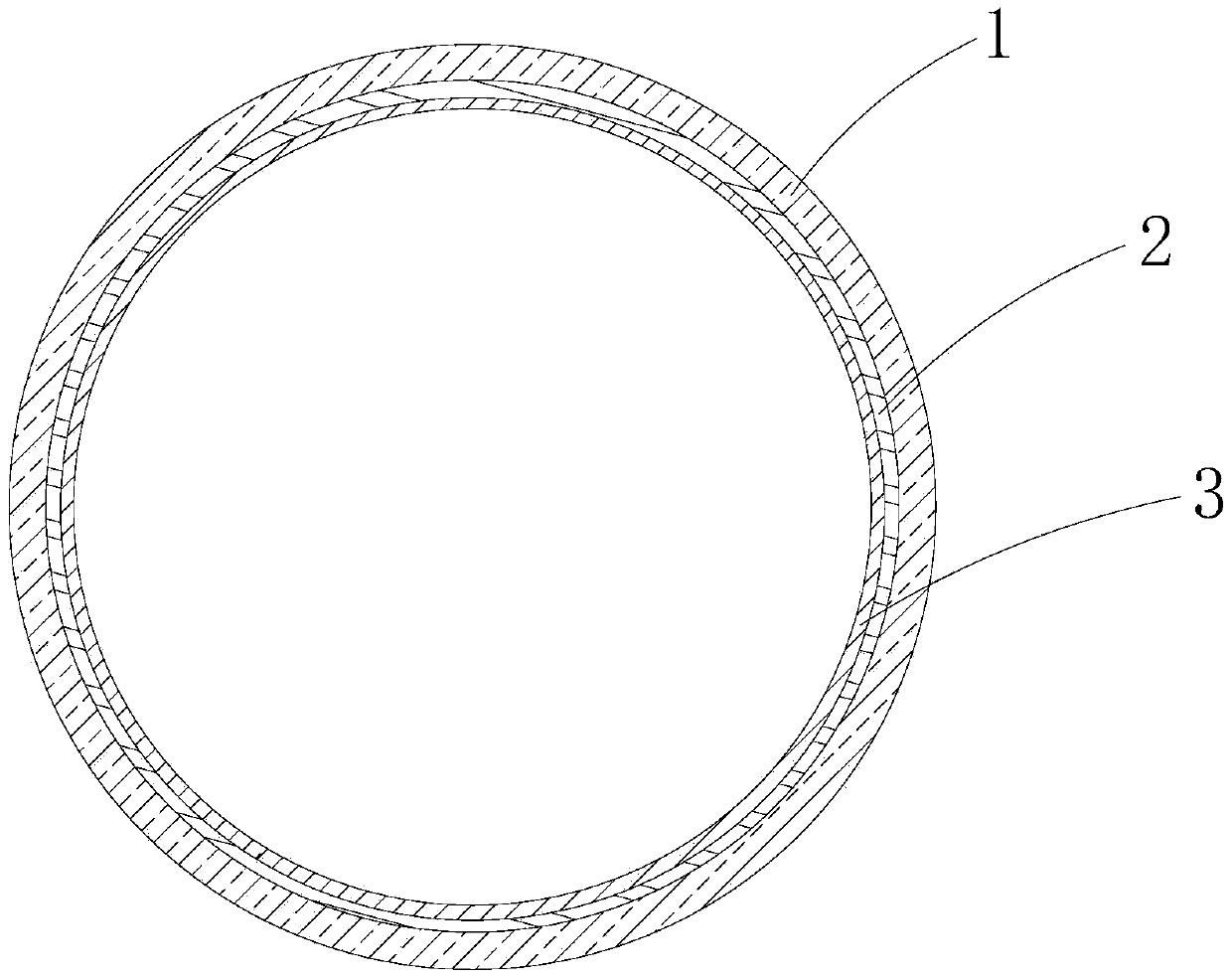

The invention relates to the technical field of oil, gas and chemical. A reinforced polyethylene complex pipeline comprises a carbon steel pipe layer, a high-density polyethylene layer and an ultra-high molecular weight polyethylene layer which are sequentially arranged from outside to inside, wherein the ultra-high molecular weight polyethylene layer and the high-density polyethylene layer are formed by melting ultra-high molecular weight polyethylene and high-density polyethylene at high temperature and high pressure and then co-extruding and forming through two die heads; a base pipe of the high-density polyethylene layer extends to the outer edge of a flange plate end surface of the carbon steel pipe layer along a pipe port in an outer layer; the carbon steel pipe layer, the high-density polyethylene layer and the ultra-high molecular weight polyethylene layer are integrally formed. The reinforced polyethylene complex pipeline is simple in structure, convenient to mount and connect, and low in use cost; the steel pipe layer and the high-density polyethylene layer at the outer layer can bear big pressure; the ultra-high molecular weight polyethylene layer at an inner layer has the effects of resisting abrasion, resisting impacting, resisting corrosion and self-lubricating. The abrasion resistance of the reinforced polyethylene complex pipeline is improved 7 to 10 times by being compared with that of a common metal conveying pipeline, thus the service life can be greatly prolonged, and the production efficiency is improved.

Description

technical field The invention relates to the technical field of oil and gas chemical industry, in particular to a reinforced polyethylene composite pipe used in the oil and gas chemical industry for the transportation of oil, gas and related materials. Background technique In recent years, plastic pipes have developed rapidly, and many new types of plastic pipes are being popularized and applied. It is a major trend to replace steel with plastic. As a new material with particularly excellent properties, ultra-high molecular weight polyethylene pipes are gradually recognized by the market. But at present, domestically produced polyethylene plastic pipes are mostly used in gas and water projects in the fields of gas, chemical industry, tap water, power plants, aluminum plants and the like. However, in the fields of gold mine, copper mine, coal mine, salt lake chemical industry, oil and gas chemical industry, etc., the friction of the powder material on the pipe is relatively...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16L9/147

CPCF16L9/147

Inventor 金红祥

Owner HAIXI HUAHUI CHEM MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com