Touch display device, driving method thereof and manufacturing method thereof

A technology of a touch display device and a manufacturing method, which are applied to static indicators, instruments, electrical digital data processing, etc., can solve the problems of affecting the size of the touch sensing signal, limiting the sensitivity of the touch sensing element, and low conductivity. , to increase the touch sensitivity, reduce the thickness and production cost, and improve the coupling capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

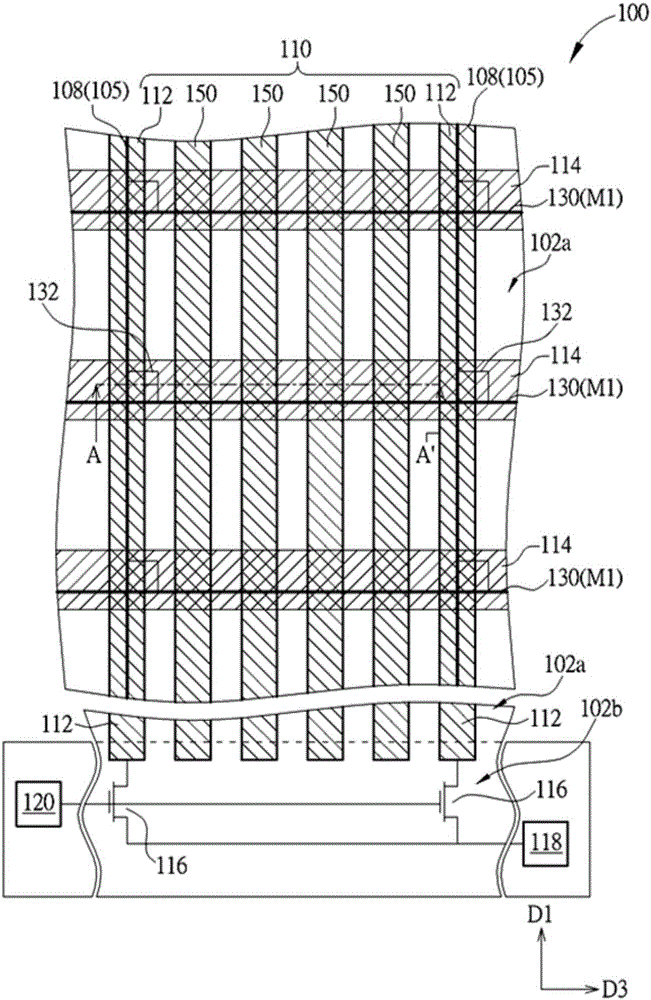

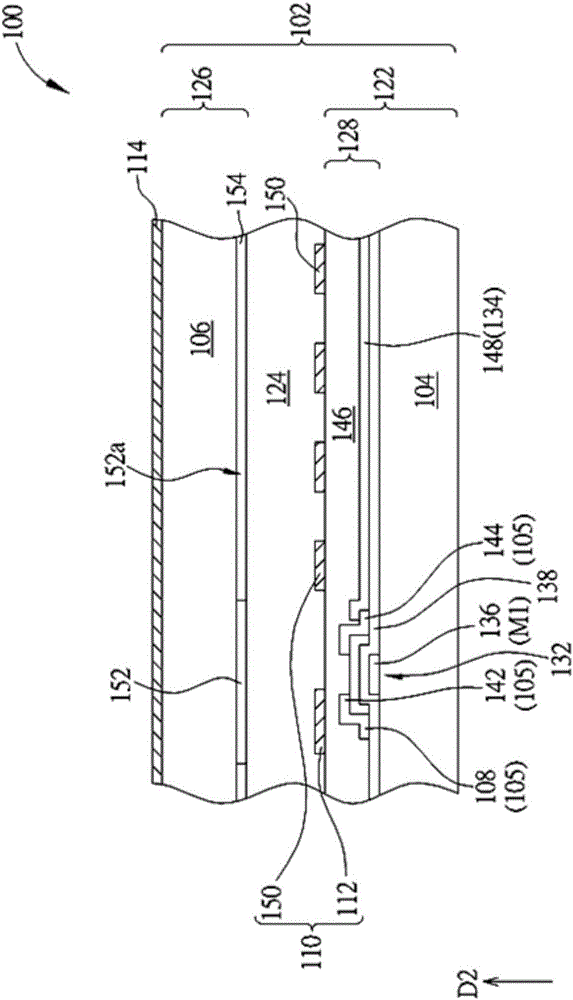

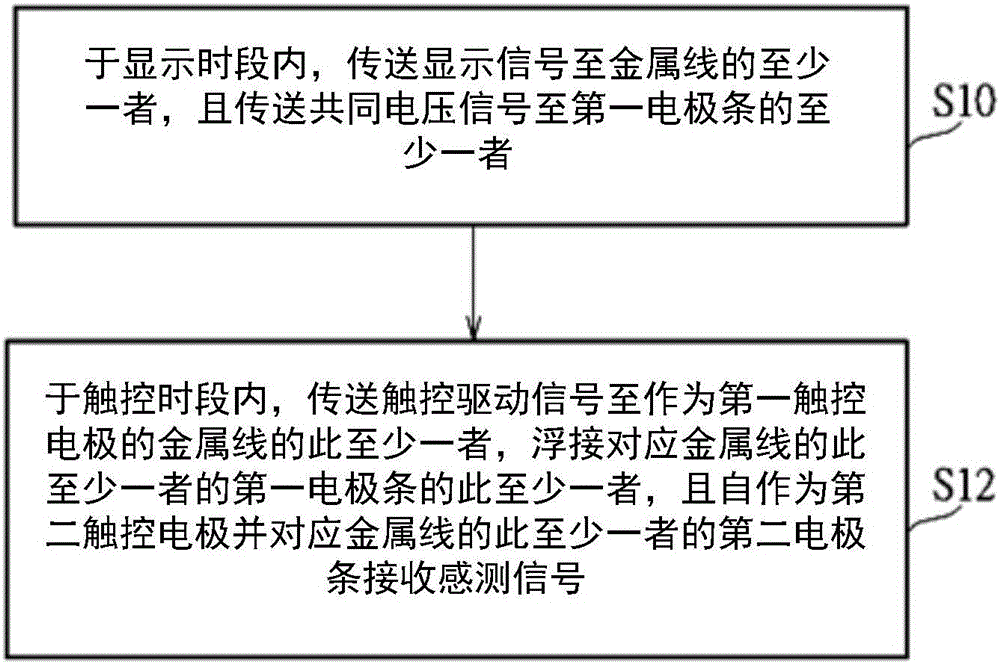

[0076] Please refer to figure 1 and figure 2 , the touch display device 100 provided by the first embodiment of the present invention includes a display panel 102 . Wherein, the display panel 102 may have an active area 102 a and a peripheral area 102 b, and the display panel 102 includes a first substrate 104 , a conductive layer 105 and a first transparent layer 110 . The conductive layer 105 is disposed on the first substrate 104 and includes a plurality of metal lines 108 . The metal lines 108 are disposed in the active region 102 a and respectively extend along a first direction D1 , and the metal lines 108 are insulated from each other. The first transparent layer 110 is disposed on the conductive layer 105, and includes a plurality of first electrode strips 112, disposed in the active region 102a, wherein each first electrode strip 112 extends along the first direction D1, and is approximately perpendicular to A second direction D2 of the first substrate 104 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com