Online infrared temperature measuring early warning system of continuous casting tundish and early warning method

A continuous casting tundish and early warning system technology, applied in the direction of radiation pyrometry, measuring devices, casting equipment, etc., can solve the problems of tundish damage, fixed monitoring points, difficult layout, etc., and achieve easy on-site management and comprehensive monitoring positions , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are examples of the present invention, which are only used for explanation of the present invention and not for limitation.

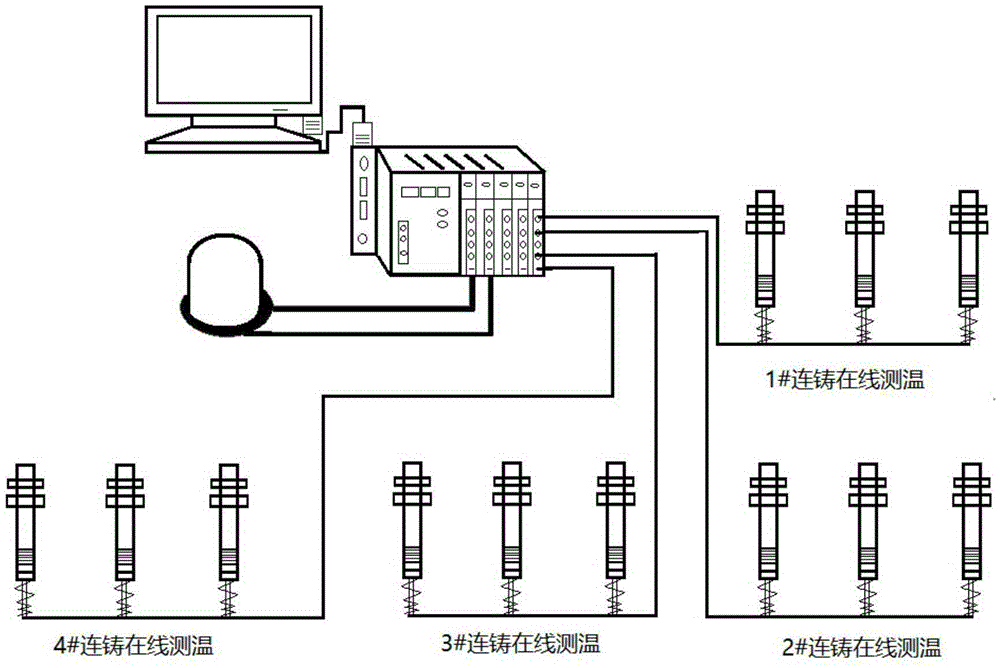

[0026] see figure 2 , the temperature measurement and early warning system of the present invention includes a temperature measurement element, a signal processing device and an early warning system, the temperature measurement element is connected to the signal processing device, and the signal processing device accepts the input of the temperature measurement element and converts it into a temperature signal, the early warning system performs early warning according to the temperature signal obtained by processing; the temperature measuring element is set at a position 2-3m away from the continuous casting tundish to be measured, and the temperature measuring element can choose an infrared temperature measuring sensor, and the infrared ray The temperature sensor can withstand a temperature of 600 degrees Celsius.

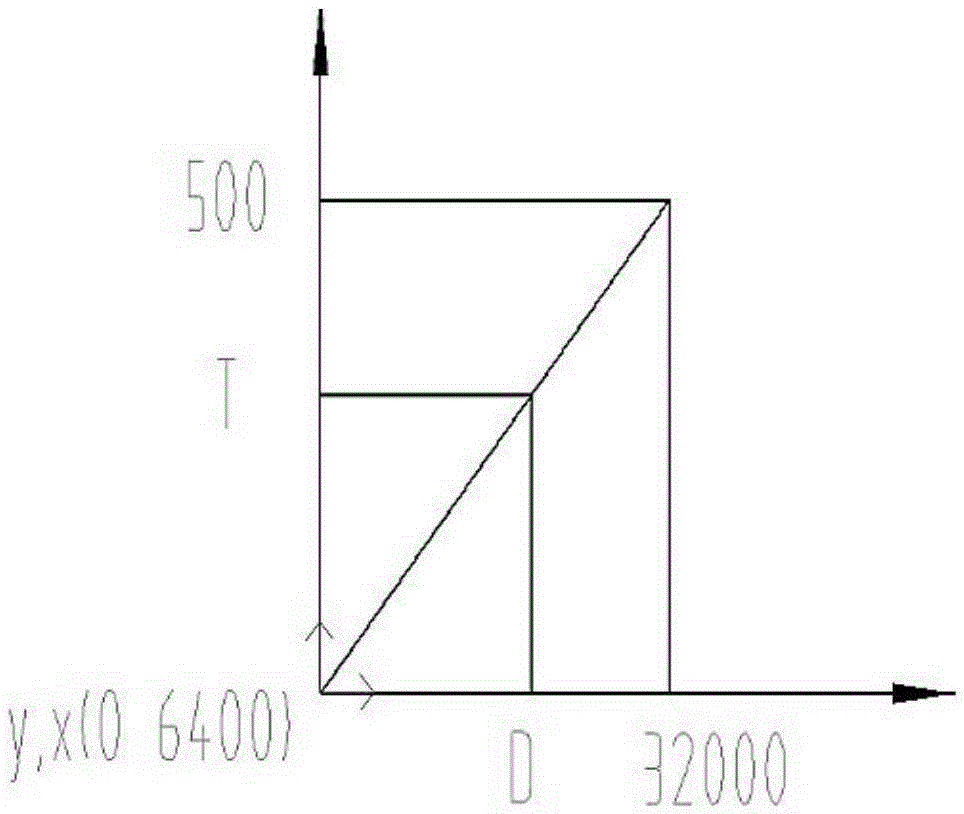

[0027] The ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com