A toughened glass cutting device adopting an abrasive blasting mode

A tempered glass and cutting device technology, which is applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of difficult to change the nozzle correctly, cannot guarantee the precise cutting size, incorrect nozzle position, etc., and achieve shortening and adjusting the nozzle position time, improve product reliability, and increase production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

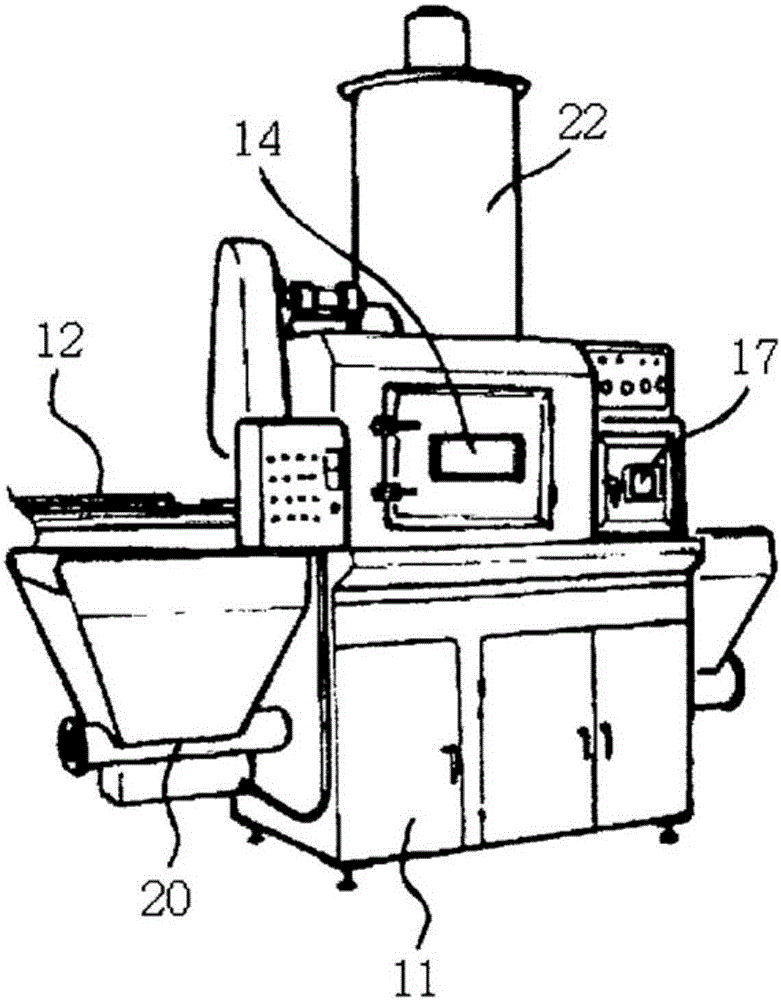

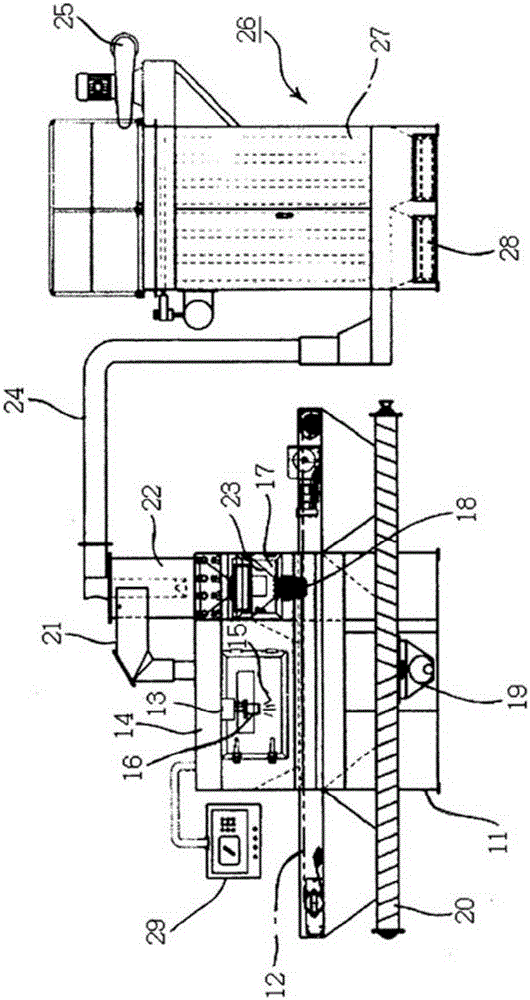

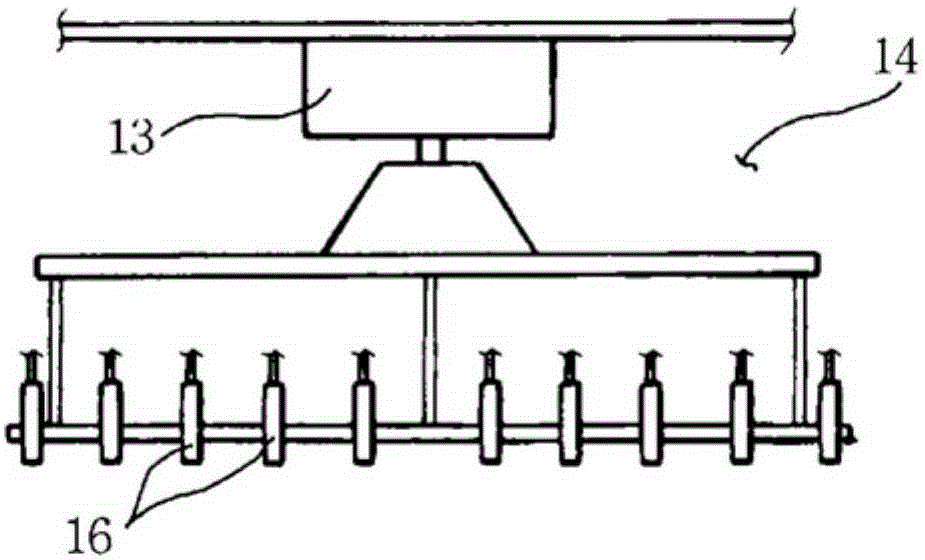

[0048] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings (the same reference numerals are used to designate the same structures as in the past, and detailed description thereof will be omitted).

[0049] The tempered glass cutting device adopting the sandblasting method of the present invention includes: a main body 11; a conveyor unit 12, which transfers the workpiece 1 to the main body 11; a chamber 14, which is arranged in the middle of the conveyor unit 12 in a sealed manner part, cutting the workpiece 1 in the chamber 14; the nozzle unit is arranged in the chamber 14 to perform the cutting operation of cutting the workpiece 1 in the X-axis and Y-axis directions; the driving unit , to provide a driving force so that the nozzle unit is moved to the X-axis or Y-axis direction; the sensor unit senses to change the position of the nozzle that is arranged in the nozzle unit; and the clean room 17 is arranged in the One ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com