Environmental barrier coating used for ceramic base composite material matrix, and making method thereof

A technology of environmental barrier coatings and composite materials, which is applied in the field of high-temperature coating preparation of aero-engines and ground gas turbines, can solve problems such as short working hours, inability to meet the requirements of long-term high-temperature environments, and inability to meet long-life work requirements. Evaporation rate, elimination of spalling and cracking, and good erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

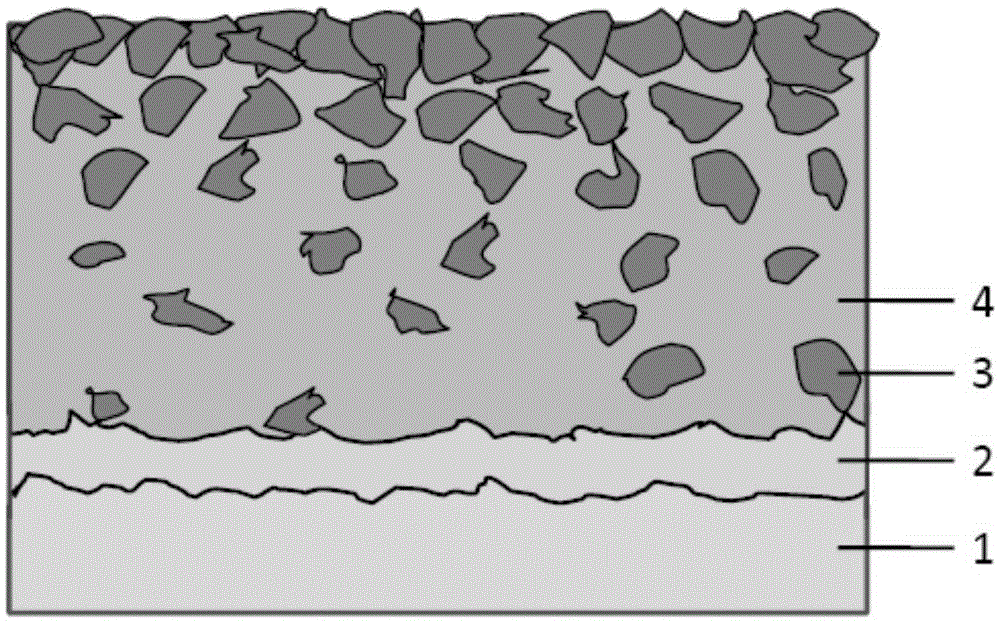

[0035] This embodiment provides a kind of environmental barrier coating for ceramic matrix composite material matrix (structural schematic diagram sees figure 1 ), the bottom layer material used when preparing the coating is SiC; the surface layer is a composite layer, the composite layer is made of yttrium silicate and mullite materials, and the chemical purity is 99.5%, and the powder particle size is 100-200 mesh Mollite. Come stone powder; the chemical purity is 99.448%, and the powder particle size is 100-200 mesh yttrium silicate powder.

[0036] The preparation process of the coating is:

[0037] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0038] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 30kW, and the spraying distance is 80mm;

...

Embodiment 2

[0045] This embodiment provides a kind of environmental barrier coating that is used for the substrate of ceramic matrix composite material, and the base material that selects when preparing coating is SiC; Surface layer is composite layer, and this composite layer is made of yttrium silicate, mullite material In the process, respectively use mullite powder with a chemical purity of 99.5% and a powder particle size of 100-200 mesh; chemical purity of 99.448% and a powder particle size of yttrium silicate powder of 100-200 mesh.

[0046] The preparation process of the coating is:

[0047] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0048] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 35kW, and the spraying distance is 90mm;

[0049] The speci...

Embodiment 3

[0056] This embodiment provides a kind of environmental barrier coating that is used for the substrate of ceramic matrix composite material, and the base material that selects when preparing coating is SiC; Surface layer is composite layer, and this composite layer is made of yttrium silicate, mullite material In the process, respectively use mullite powder with a chemical purity of 99.5% and a powder particle size of 100-200 mesh; chemical purity of 99.448% and a powder particle size of yttrium silicate powder of 100-200 mesh.

[0057] The preparation process of the coating is:

[0058] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0059] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 35kW, and the spraying distance is 90mm;

[0060] The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com