A kind of environmental barrier coating for ceramic matrix composite material matrix and its preparation method

An environmental barrier coating and composite material technology, which is applied in the field of high-temperature coating preparation for aero-engines and ground gas turbines, can solve problems such as incompetence for long-term high-temperature environment requirements, short working hours, and inability to meet long-life work requirements, etc., to eliminate Peeling and cracking, low volatility, good erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

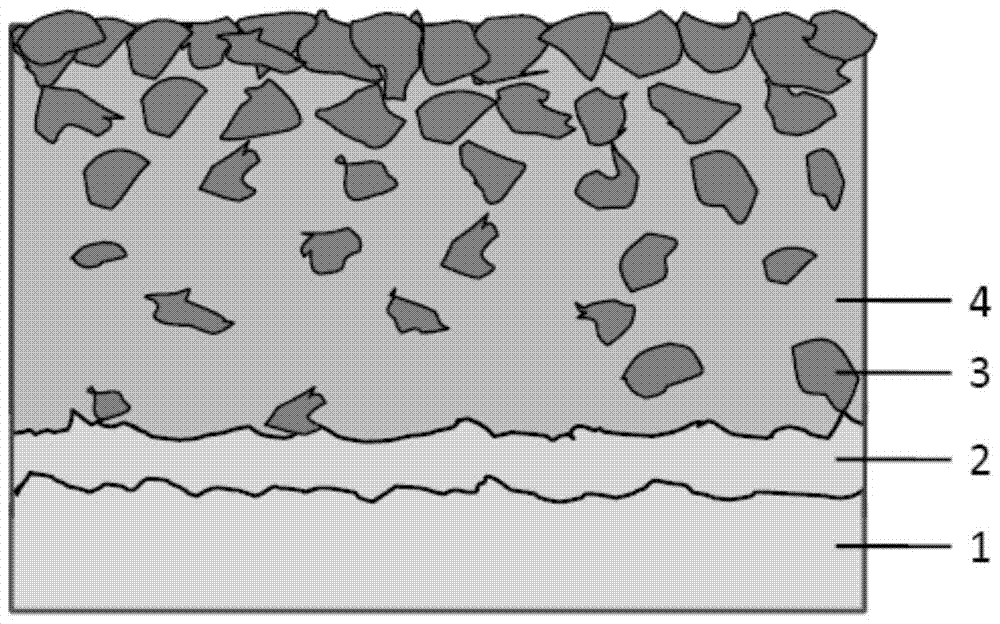

[0035] This embodiment provides a kind of environmental barrier coating for ceramic matrix composite material matrix (structural schematic diagram sees figure 1 ), the bottom layer material used when preparing the coating is SiC; the surface layer is a composite layer, the composite layer is made of yttrium silicate and mullite materials, and the chemical purity is 99.5%, and the powder particle size is 100-200 mesh Mollite. Come stone powder; the chemical purity is 99.448%, and the powder particle size is 100-200 mesh yttrium silicate powder.

[0036] The preparation process of the coating is:

[0037] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0038] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 30kW, and the spraying distance is 80mm;

...

Embodiment 2

[0045] This embodiment provides a kind of environmental barrier coating that is used for the substrate of ceramic matrix composite material, and the base material that selects when preparing coating is SiC; Surface layer is composite layer, and this composite layer is made of yttrium silicate, mullite material In the process, respectively use mullite powder with a chemical purity of 99.5% and a powder particle size of 100-200 mesh; chemical purity of 99.448% and a powder particle size of yttrium silicate powder of 100-200 mesh.

[0046] The preparation process of the coating is:

[0047] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0048] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 35kW, and the spraying distance is 90mm;

[0049] The speci...

Embodiment 3

[0056] This embodiment provides a kind of environmental barrier coating that is used for the substrate of ceramic matrix composite material, and the base material that selects when preparing coating is SiC; Surface layer is composite layer, and this composite layer is made of yttrium silicate, mullite material In the process, respectively use mullite powder with a chemical purity of 99.5% and a powder particle size of 100-200 mesh; chemical purity of 99.448% and a powder particle size of yttrium silicate powder of 100-200 mesh.

[0057] The preparation process of the coating is:

[0058] 1. Use chemical vapor deposition technology to prepare SiC coating on the ceramic matrix composite material substrate as the bottom layer, and the thickness is controlled at about 100 μm.

[0059] 2. Use plasma spraying technology to spray the surface layer on the bottom layer, which is a composite layer; the plasma spraying power is 35kW, and the spraying distance is 90mm;

[0060] The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com