Cocatalyst composition and application thereof

A co-catalyst and composition technology, applied in the field of copolymerization of alkenes and cyclic olefins, can solve the problem of unsatisfactory glass transition temperature of copolymers

- Summary

- Abstract

- Description

- Claims

- Application Information

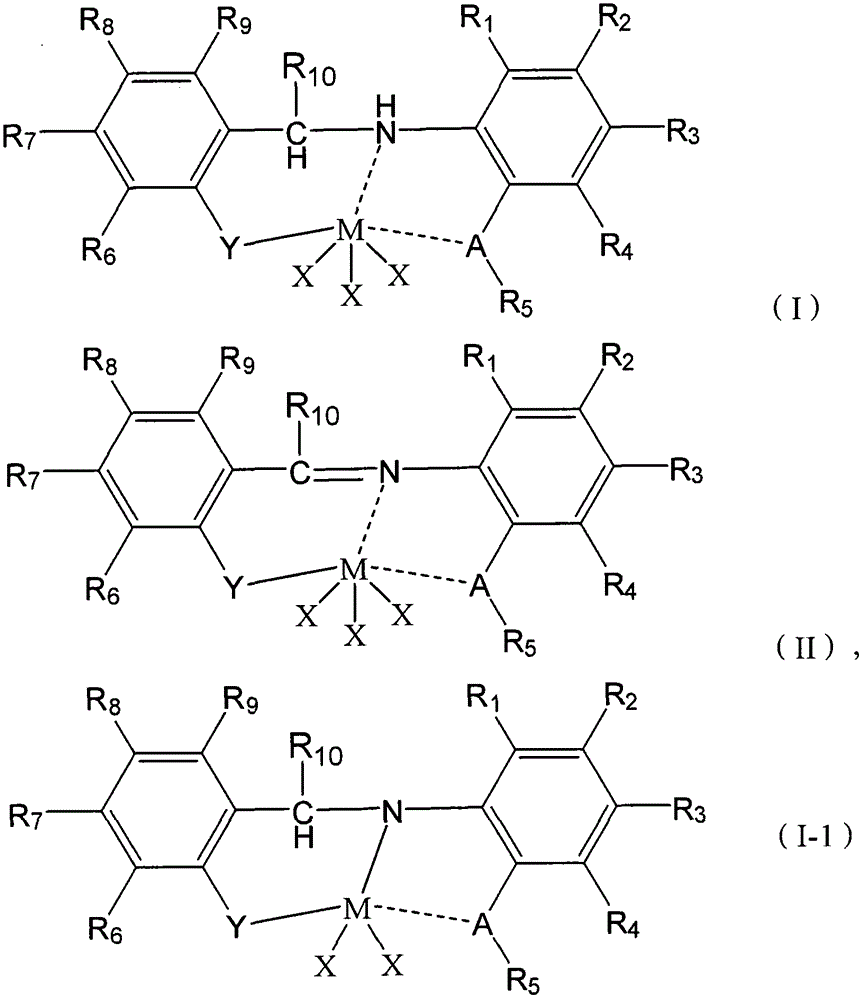

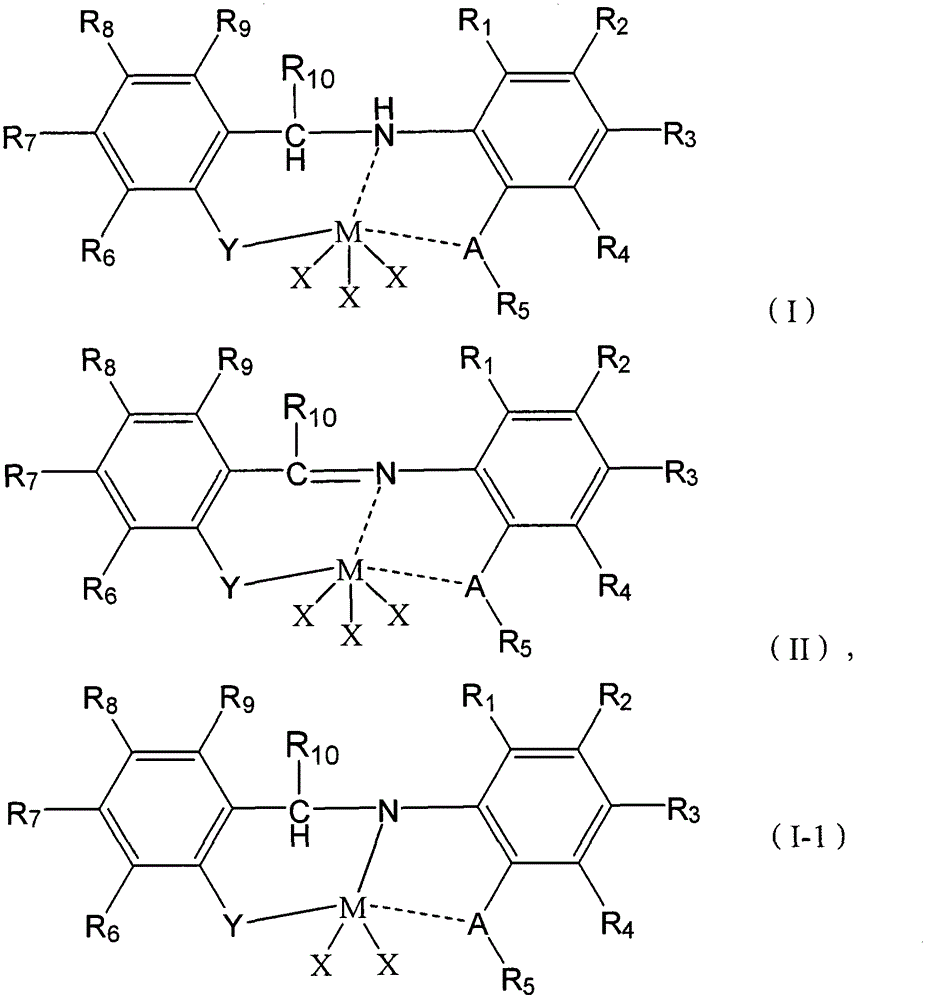

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0210] The following examples will be used to illustrate the present invention in further detail, but the present invention is not limited to these examples.

[0211] The various performance parameters involved in the following examples and comparative examples were measured according to the following methods.

[0212] (1) Polymerization activity

[0213] Catalyst polymerization activity (unit is g(P)·(mol(M)·h) -1 , where P refers to the copolymer, M refers to the metal element M such as Ti) is calculated according to the following formula:

[0214] Polymerization activity = m 1 ×4×Mw / m 2

[0215] in,

[0216] m 1 The amount (g) of copolymer obtained for 15 minutes of polymerization time;

[0217] Mw is the molecular weight of catalyst;

[0218] m 2 is the amount of catalyst added (g).

[0219] (2) Molecular weight Mη of polymer

[0220] The viscosity-average molecular weight Mη of polymer is calculated according to the following method:

[0221] According to the ...

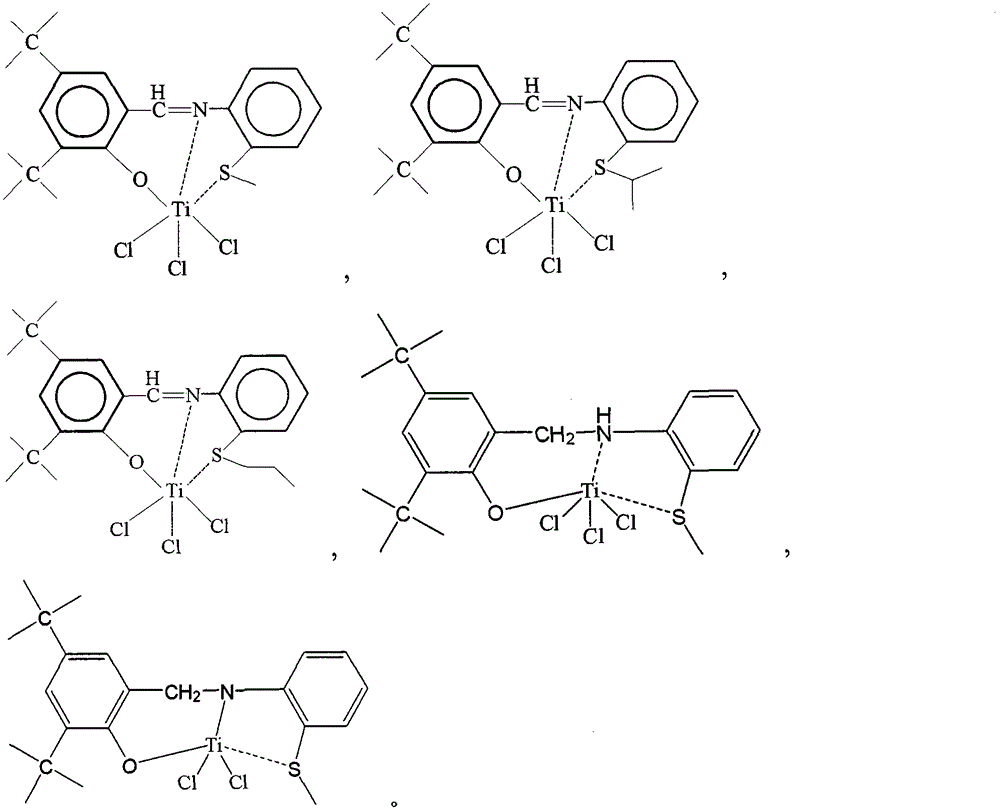

manufacture Embodiment 1

[0228] In a dry 500ml three-necked flask, add 2-aminoanisole sulfide (0.2mol), absolute ethanol (160ml), 3,5-di-tert-butyl salicylaldehyde (0.2mol), acetic acid (0.3ml) successively , heated up to reflux temperature and reacted for 2hr, cooled to room temperature, filtered, washed three times with absolute ethanol, and dried in vacuum to obtain 49.7g of 2-aminoanisole sulfide 3,5-di-tert-butyl salicylaldehyde, called Ligand L1,

[0229]

[0230] L1.

[0231] Elemental analysis: C74.57% (theoretical value 74.32%); H8.35% (theoretical value 8.22%); N4.07% (theoretical value 3.94%). 1 H NMR δ=13.4(OH), 8.6(CHN), 7.5-7.1(Ar-H), 3.25(SCH 3 ), 1.45 (C (CH 3 ) 3 ), 1.35 (C (CH 3 ) 3 ).

manufacture Embodiment 2

[0233] In a dry 500ml three-necked flask, add 2-aminophenylpropyl sulfide (0.2mol), absolute ethanol (160ml), 3,5-di-tert-butyl salicylaldehyde (0.2mol), acetic acid (0.3ml) successively , heated up to reflux temperature and reacted for 2hr, cooled to room temperature, filtered, washed three times with absolute ethanol, and dried in vacuum to obtain 49.7g of 2-aminophenylpropyl sulfide 3,5-di-tert-butyl salicylaldehyde, called Ligand L2,

[0234]

[0235] L2.

[0236] Elemental analysis: C74.57% (theoretical value 75.15%); H8.35% (theoretical value 8.67%); N3.95% (theoretical value 3.65%). 1 H NMR δ=13.4(OH), 8.55(CHN), 7.5-7.1(Ar-H), 2.10(CH 2 CH 3 ), 1.47 (C (CH 3 ) 3 ), 1.35 (C (CH 3 ) 3 ), 1.17 (CH 2 CH 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com