High temperature resistant low voltage variable light-colored acrylonitrile-butadiene rubber formula for skeleton oil seal

A technology of nitrile rubber and skeleton oil seal, which is applied in the field of rubber technology formula, can solve the problems of being unable to be widely used, slow vulcanization speed, and vulcanization delay, etc., achieves the effects of fast vulcanization speed, improved high temperature aging resistance, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

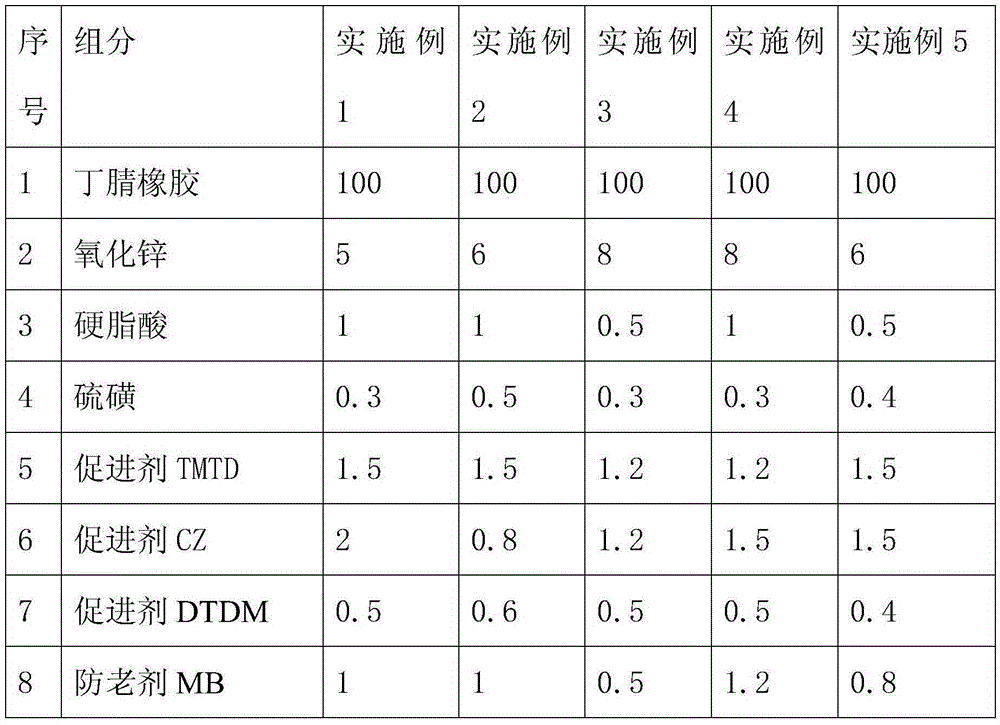

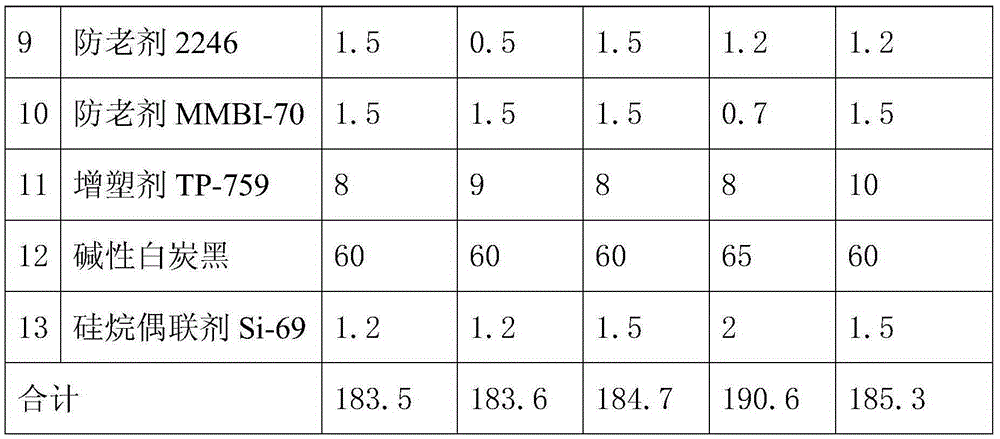

[0010] The high-temperature-resistant and low-pressure light-colored nitrile-butadiene rubber formulation components used for skeleton oil seals of the present invention are as shown in Table 1:

[0011] Table 1. High-temperature-resistant and low-pressure light-colored nitrile-butadiene rubber formulation component list for skeleton oil seal of the present invention

[0012] serial number

components

1

Nitrile rubber

100

2

3~10

3

1~6

[0013] 4

0.2~1.5

5

Accelerator TMTD

0.5~2.5

6

Accelerator CZ

1~3

7

Accelerator DTDM

0.5~2.5

8

Antiager MB

0.5~3.5

9

Antiaging agent 2246

0.5~3.5

10

Antiaging agent MMBI-70

0.5~2

11

Plasticizer TP-759

5~15

12

Basic silica

40~70

13

1~3

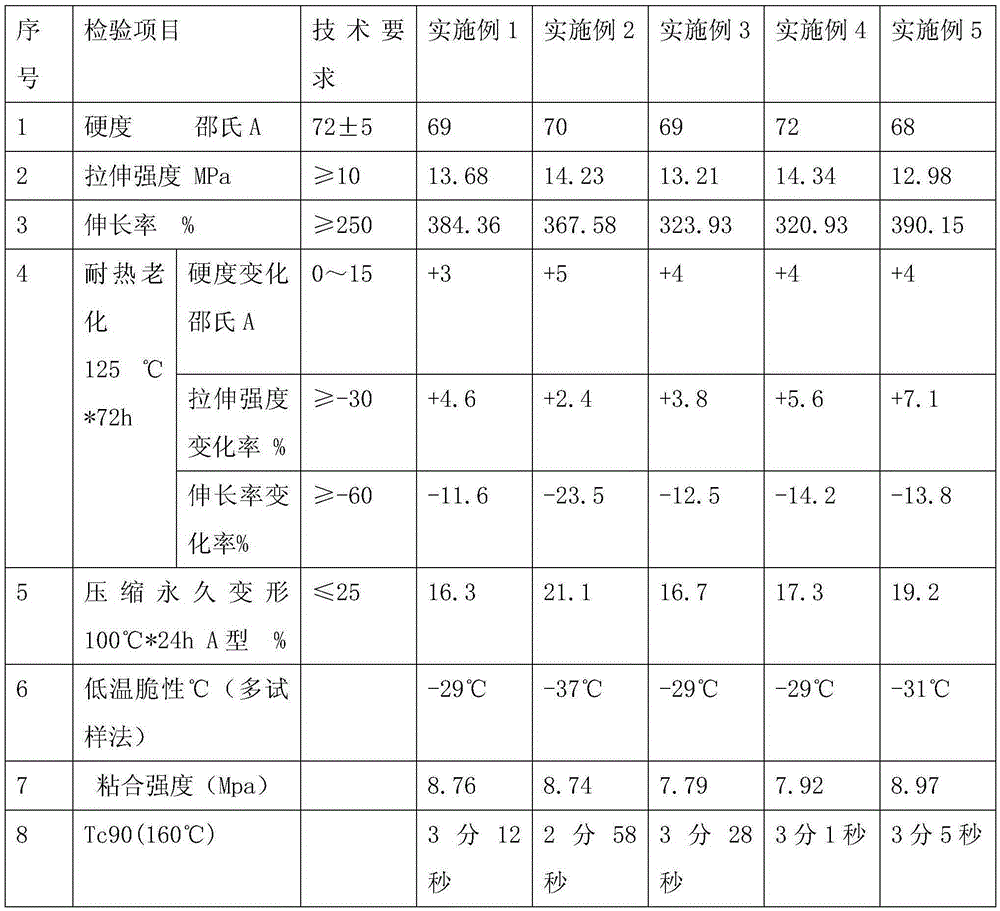

[0014] Embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness change | aaaaa | aaaaa |

| elongation change rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com