Hollow glass micro-bead reinforced polypropylene material

A technology of hollow glass microspheres and polypropylene materials, applied in the field of polypropylene material production, can solve problems such as poor creep resistance, variability, and large shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Take each raw material respectively by weight ratio as follows:

[0015] Polypropylene: 70;

[0016] Silane coupling agent: 1.0;

[0017] Antioxidant: 1.0;

[0018] Hollow glass microspheres: 10;

[0019] Dispersed lubricant: 0.5;

[0020] Dispersant: 0.5.

[0021] (2) First surface activate the hollow glass microspheres and silane coupling agent, then dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder for melt extrusion , cooling, pelletizing, and packaging the finished product; among them, the temperature of the first zone of the twin-screw extruder is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, and the fourth zone is 200-205°C ; The fifth zone is 190-200°C, the residence time is 1-2 minutes, and the pressure is 10-15Mpa.

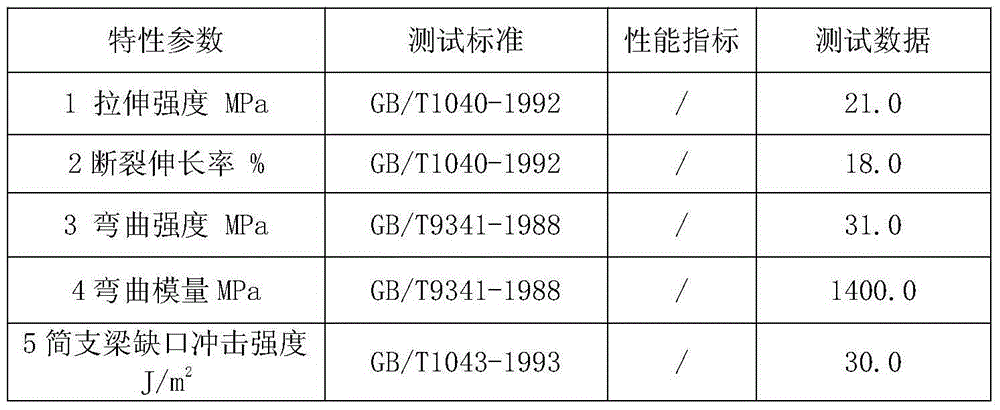

[0022] Experimental results

[0023]

Embodiment 2

[0025] (1) Take each raw material respectively by weight ratio as follows:

[0026] Polypropylene: 75;

[0027] Silane coupling agent: 2.0;

[0028] Antioxidant: 2.0;

[0029] Hollow glass microspheres: 20;

[0030] Dispersed Lubricant: 1.0;

[0031] White oil: 1.0.

[0032] (2) First surface activate the hollow glass microspheres and silane coupling agent, then dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder for melt extrusion , cooling, pelletizing, and packaging the finished product; among them, the temperature of the first zone of the twin-screw extruder is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, and the fourth zone is 200-205°C ; The fifth zone is 190-200°C, the residence time is 1-2 minutes, and the pressure is 10-15Mpa.

[0033] Experimental results

[0034]

Embodiment 3

[0036] (1) Take each raw material respectively by weight ratio as follows:

[0037] Polypropylene: 80;

[0038] Silane coupling agent: 3.0;

[0039] Antioxidant: 3.0;

[0040] Hollow glass microspheres: 30;

[0041] Dispersed lubricant: 1.5;

[0042] Dispersant: 1.5.

[0043] (2) First surface activate the hollow glass microspheres and silane coupling agent, then dry mix the above-mentioned various raw materials in a high-speed mixer for 3-5 minutes, and then put them in a twin-screw extruder for melt extrusion , cooling, pelletizing, and packaging the finished product; among them, the temperature of the first zone of the twin-screw extruder is 90-100°C, the second zone is 150-180°C, the third zone is 200-210°C, and the fourth zone is 200-205°C ; The fifth zone is 190-200°C, the residence time is 1-2 minutes, and the pressure is 10-15Mpa.

[0044] Experimental results

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com