Low-temperature antifreezing agent and preparation method thereof

A technology of antifreeze and low temperature, applied in the field of low temperature antifreeze and its preparation, can solve the problems of poor antifreeze and anti-icing performance, and achieve the effect of excellent anti-icing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

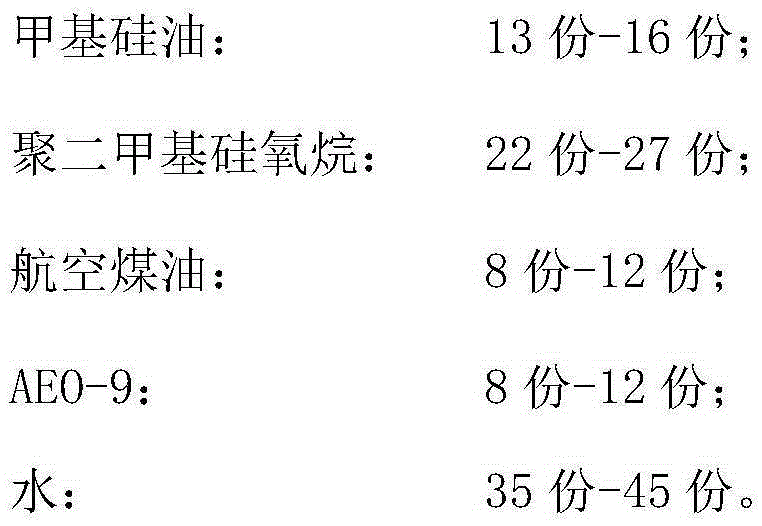

[0023] A low-temperature antifreeze, which comprises the following components in parts by mass,

[0024]

[0025] Experiments have proved that the antifreeze performance of the antifreeze agent is better than that of existing antifreeze agent products under extremely low temperature conditions.

example 2

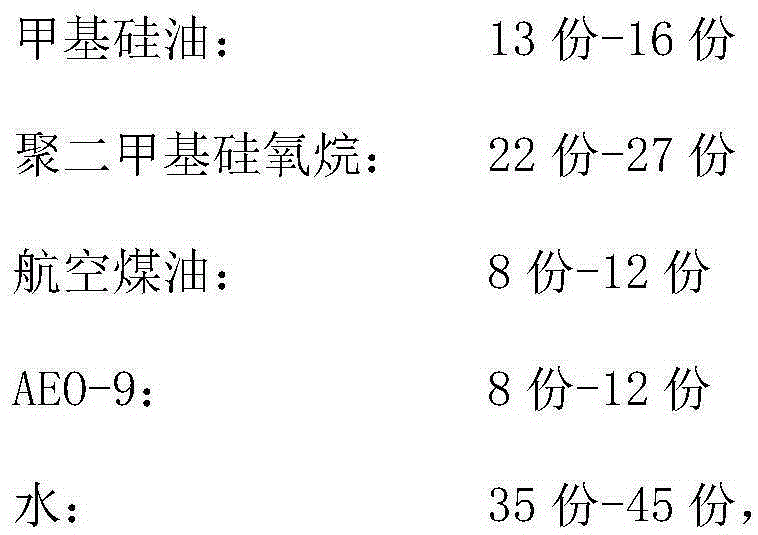

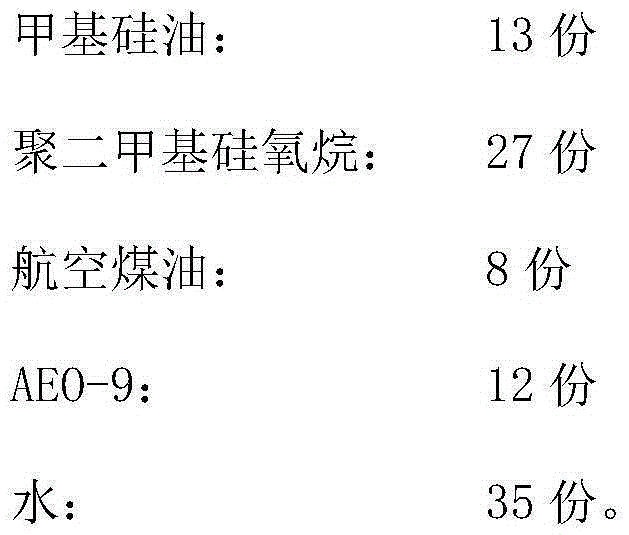

[0027] A low-temperature antifreeze, which comprises the following components in parts by mass,

[0028]

[0029] Experiments have proved that the antifreeze performance of the antifreeze agent is better than that of existing antifreeze agent products under extremely low temperature conditions.

[0030] A preparation method of a low-temperature antifreeze, the method comprising the steps of:

[0031] (1) Mix 8-12 parts of AEO-9 and 35-45 parts of water according to the parts by mass;

[0032] (2) Stir the mixed solution of AEO-9 and water;

[0033] (3) Add 13-16 parts of methyl silicone oil, 22-27 parts of polydimethylsiloxane, 8-12 parts of Aviation kerosene obtains the final mixture;

[0034] (4) Stir the final mixed solution to obtain the final product evenly.

[0035] In the specific implementation of the present invention, the stirring time in the step (4) is 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com