Wind turbine blade edge protection paint based on bio-based polyol

A bio-based polyol, wind power blade technology, applied in coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve problems such as the environment and occupational health injuries of construction workers, and achieve large-scale production, high construction efficiency, and curing speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A wind power blade edge protection paint based on bio-based polyols, the main paint contains 20 parts of bio-based polyol A, 25 parts of bio-based polyol B, 5 parts of reactive diluent SOVERMOL 1102, 15 parts of rutile titanium dioxide R902+ , 15 parts of precipitated barium sulfate, 0.05 parts of drier dibutyltin dilaurate, 0.5 parts of dispersant BYK110, 0.5 parts of leveling agent EFKA3777, 0.5 parts of defoamer BYK066N, 0.5 parts of anti-settling agent BENTONE 38, 1.35 parts of anti-aging Agent Tinuvin 1130, 0.65 parts of Tinuvin292.

[0029] The curing agent is N3900, and the main paint and curing agent are mixed evenly at a mass ratio of 2:1 to make a sample for testing.

Embodiment 2

[0031] A wind power blade edge protection paint based on bio-based polyols, the main paint contains 40 parts of bio-based polyol A, 10 parts of bio-based polyol B, 15 parts of reactive diluent SOVERMOL 1102, 35 parts of rutile titanium dioxide R930 , 30 parts of precipitated barium sulfate, 0.1 part of drier stannous octoate, 1.5 parts of dispersant EFKA4010, 0.5 parts of leveling agent BYK306, 0.7 parts of leveling agent BYK358, 1.2 parts of defoamer BYK085, 1.5 parts of anti-settling agent gas phase Silica R972, 2.1 parts of anti-aging agent Tinuvin1130, 1.9 parts of Tinuvin 292.

[0032] The curing agent is HXLV, and the main paint and curing agent are mixed uniformly at a mass ratio of 3:1 to make a sample for testing.

Embodiment 3

[0034] A wind power blade edge protection paint based on bio-based polyols, the main paint contains 25 parts of bio-based polyol A, 18 parts of bio-based polyol B, 10 parts of reactive diluent SOVERMOL 1102, 18 parts of rutile titanium dioxide R706 , 25 parts of precipitated barium sulfate, 0.05 part of drier dibutyltin dilaurate, 0.8 part of dispersant EFKA4010, 0.1 part of leveling agent BYK306, 0.7 part of leveling agent BYK358, 0.9 part of defoamer BYK085, 0.9 part of anti-settling agent Polyamide wax SUPER, 1.7 parts of anti-aging agent Tinuvin1130, 0.85 parts of Tinuvin 292.

[0035] The curing agent is a mixture of HXLV and N3900 in equal weight ratios. The main paint and curing agent are mixed uniformly at a mass ratio of 2.5:1 to make a sample for testing.

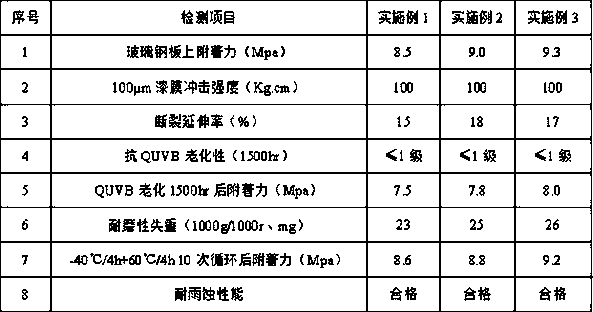

[0036] The performance index of each model among the embodiment 1~3 is as follows:

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com