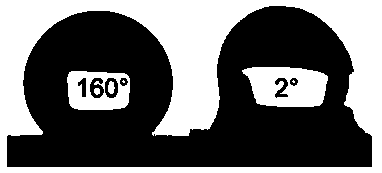

A durable anti-icing superhydrophobic coating and preparation method thereof

A super-hydrophobic coating, durable technology, applied in coatings, devices for coating liquids on surfaces, pre-treatment surfaces, etc., can solve the problem of losing super-hydrophobicity, and achieve excellent ice resistance and good wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) After the steel is polished, the groove structure is obtained by laser treatment. The depth of the concave structure is 250 μm, and the width is 100 μm; the width of the convex structure is 120 μm;

[0024] (2) After cleaning the sample obtained in step (1), spray a decahydronaphthalene solution with a concentration of 4 g / L ultra-high molecular polyethylene on the surface of the groove structure and dry it to obtain an intermediate polymer layer.

[0025] (3) Al with a particle size of 70 nm 2 o 3 Particles were immersed in 0.06 mol / L ethanol solution of heptadecafluorodecyltriethoxysilane at a temperature of 55 °C for 3.5 h.

[0026] (4) The hydrophobic nano-Al obtained in step (3) 2 o 3 Particles and ultra-high molecular polyethylene are added to decahydronaphthalene to keep Al 2 o 3 The concentration is 35 g / L, and the concentration of ultra-high molecular weight polyethylene is 8 g / L. The above mixture is heated to 150 °C, sprayed on the coating described...

Embodiment 2

[0029] (1) After the steel is polished, the groove structure is obtained by laser treatment. The depth of the concave structure is 200 μm, and the width is 150 μm; the width of the convex structure is 100 μm;

[0030] (2) After cleaning the sample obtained in step (1), spray a decahydronaphthalene solution with a concentration of 5 g / L ultra-high molecular polyethylene on the surface of the groove structure and dry it to obtain an intermediate polymer layer.

[0031] (3) Al with a particle size of 50 nm 2 o 3 Particles were soaked in 0.07 mol / L ethanol solution of heptadecafluorodecyltriethoxysilane, the soaking temperature was 50 °C, and the soaking time was 4 h.

[0032] (4) The hydrophobic nano-Al obtained in step (3) 2 o 3 Particles and ultra-high molecular polyethylene are added to decahydronaphthalene to keep Al 2 o 3 The concentration is 40 g / L, and the concentration of ultra-high molecular weight polyethylene is 6 g / L. The above mixture is heated to 150 °C, spray...

Embodiment 3

[0035] (1) After the steel is polished, the groove structure is obtained by laser treatment. The depth of the concave structure is 300 μm, and the width is 50 μm; the width of the convex structure is 200 μm;

[0036] (2) After cleaning the sample obtained in step (1), spray a decahydronaphthalene solution with a concentration of 3 g / L ultra-high molecular polyethylene on the surface of the groove structure and dry it to obtain an intermediate polymer layer.

[0037] (3) Al with a particle size of 90 nm 2 o 3 Particles were soaked in 0.08 mol / L ethanol solution of heptadecafluorodecyltriethoxysilane, the soaking temperature was 60 °C, and the soaking time was 3 h.

[0038] (4) The hydrophobic nano-Al obtained in step (3) 2 o 3 Particles and ultra-high molecular polyethylene are added to decahydronaphthalene to keep Al 2 o 3The concentration is 30 g / L, and the ultra-high molecular weight polyethylene concentration is 8 g / L. The above mixture is heated to 150 °C, sprayed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com