A kind of chenille bath towel and its manufacturing process

A manufacturing process and a technology for rubbing bath towels, which are applied in textiles and papermaking, fabrics, textiles, etc., can solve the problems of poor visual effect and no novelty, improve grade and market competitiveness, have strong three-dimensional sense and good air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

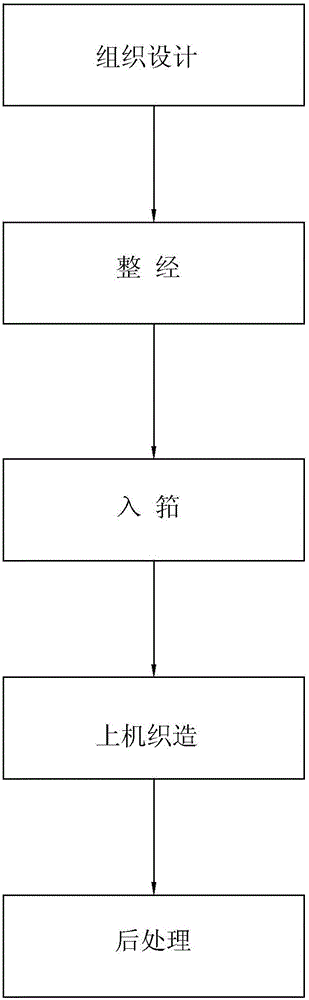

[0026] The invention discloses a manufacturing process of a chenille bath towel, including weave design, warping, reeding, heald and weaving on a machine.

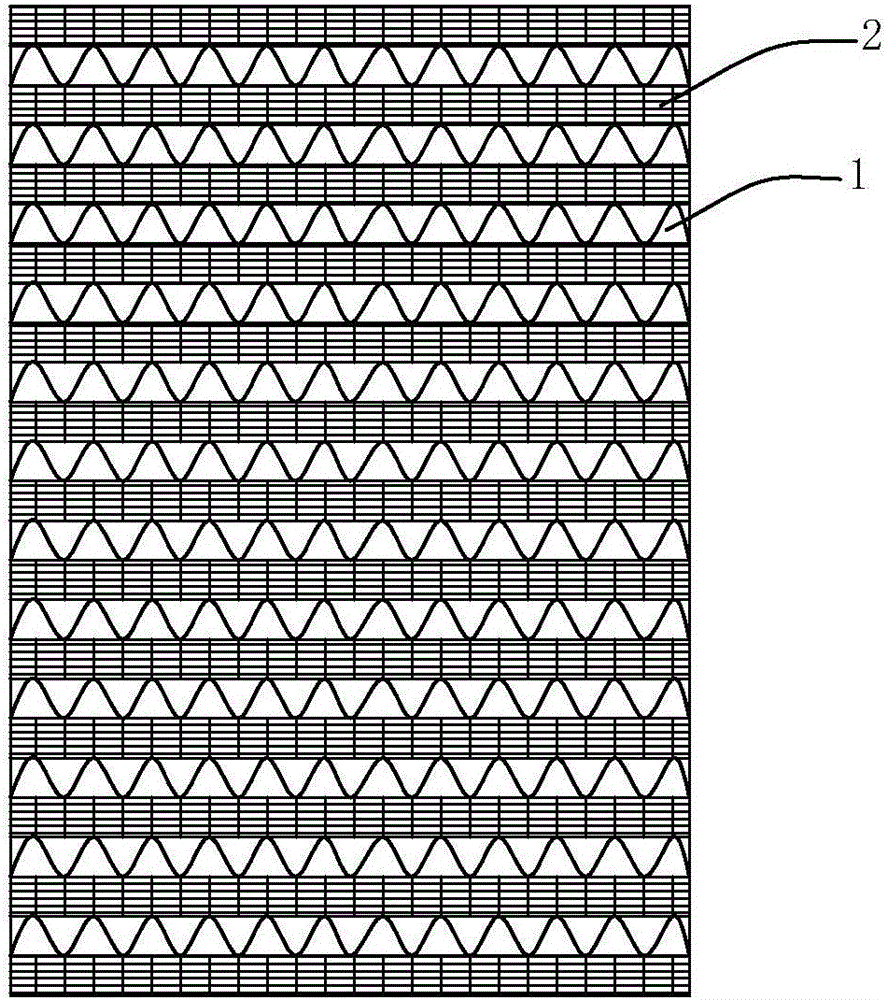

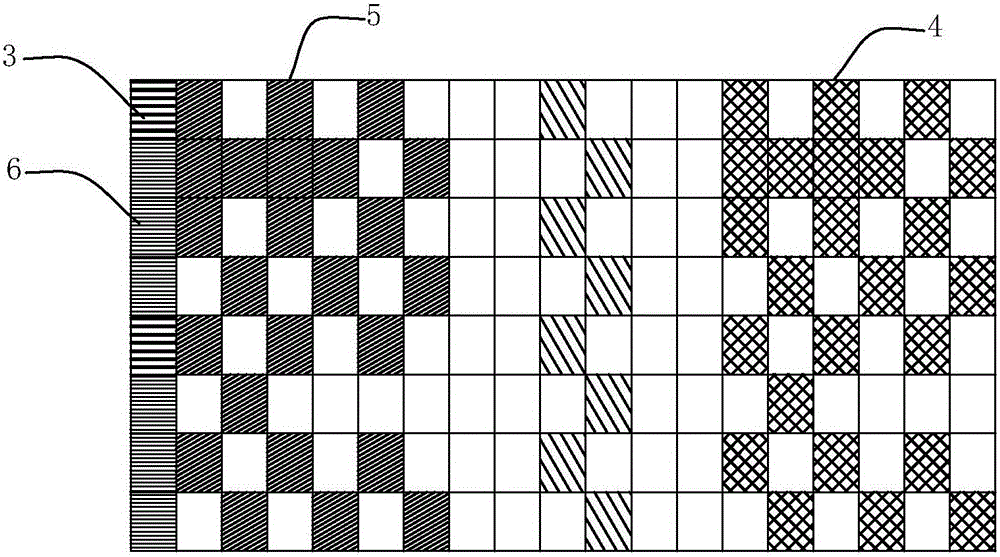

[0027] Weave design, designed using a special weaving process, the bath towel has a three-dimensional horizontal wrinkle weave and a flat cloth weave, the weft yarn includes chenille yarn and combed cotton yarn, and the chenille yarn is interwoven with the wool warp and the ground warp The three-dimensional horizontal wrinkle structure is formed, and the combed cotton yarn is interwoven with the wool warp and the ground warp to form a plain cloth structure.

[0028] Warping, according to the regulations of the organization design, a certain number and length of warp yarns (including hair warp and ground warp) are drawn from the winding bobbin to form a piece of yarn, so that the warp yarns have uniform tension and are parallel to each other. Wrapped tightly around the warp beam, it is initially prepared for forming a beam....

Embodiment 2

[0033] Such as image 3 Shown, a kind of manufacturing process of chenille bath towel, including weave design, warping, reeding, weaving, post-processing, post-processing includes deboiling, bleaching, desizing and softening, loose drying And high temperature tentering treatment.

[0034] Weave design, designed using a special weaving process, the bath towel has a three-dimensional horizontal wrinkle weave and a flat cloth weave, the weft yarn includes chenille yarn and combed cotton yarn, and the chenille yarn is interwoven with the wool warp and the ground warp The three-dimensional horizontal wrinkle structure is formed, and the combed cotton yarn is interwoven with the wool warp and the ground warp to form a plain cloth structure.

[0035] Warping, according to the regulations of the organization design, a certain number and length of warp yarns (including hair warp and ground warp) are drawn from the winding bobbin to form a piece of yarn, so that the warp yarns have uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com